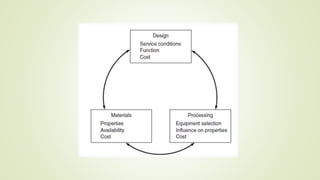

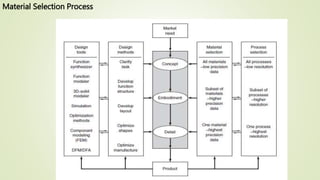

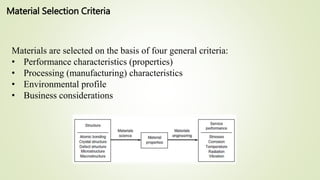

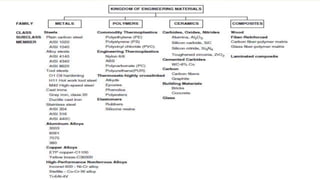

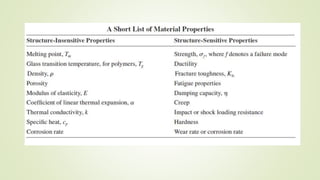

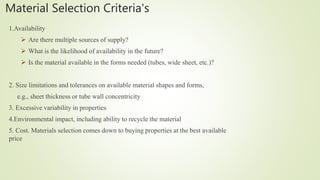

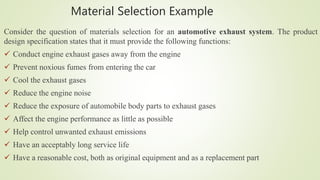

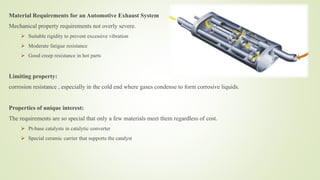

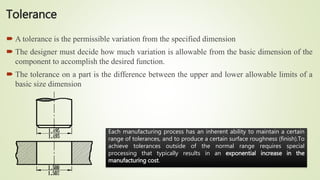

The document outlines the material selection process in engineering, emphasizing criteria such as performance characteristics, processing capabilities, environmental impact, and cost considerations. It provides an example related to automotive exhaust systems and highlights the importance of various materials based on specific mechanical properties and tolerances. Additionally, it discusses engineering standards and codes as essential tools for ensuring safety, compatibility, and effective communication across the industry.