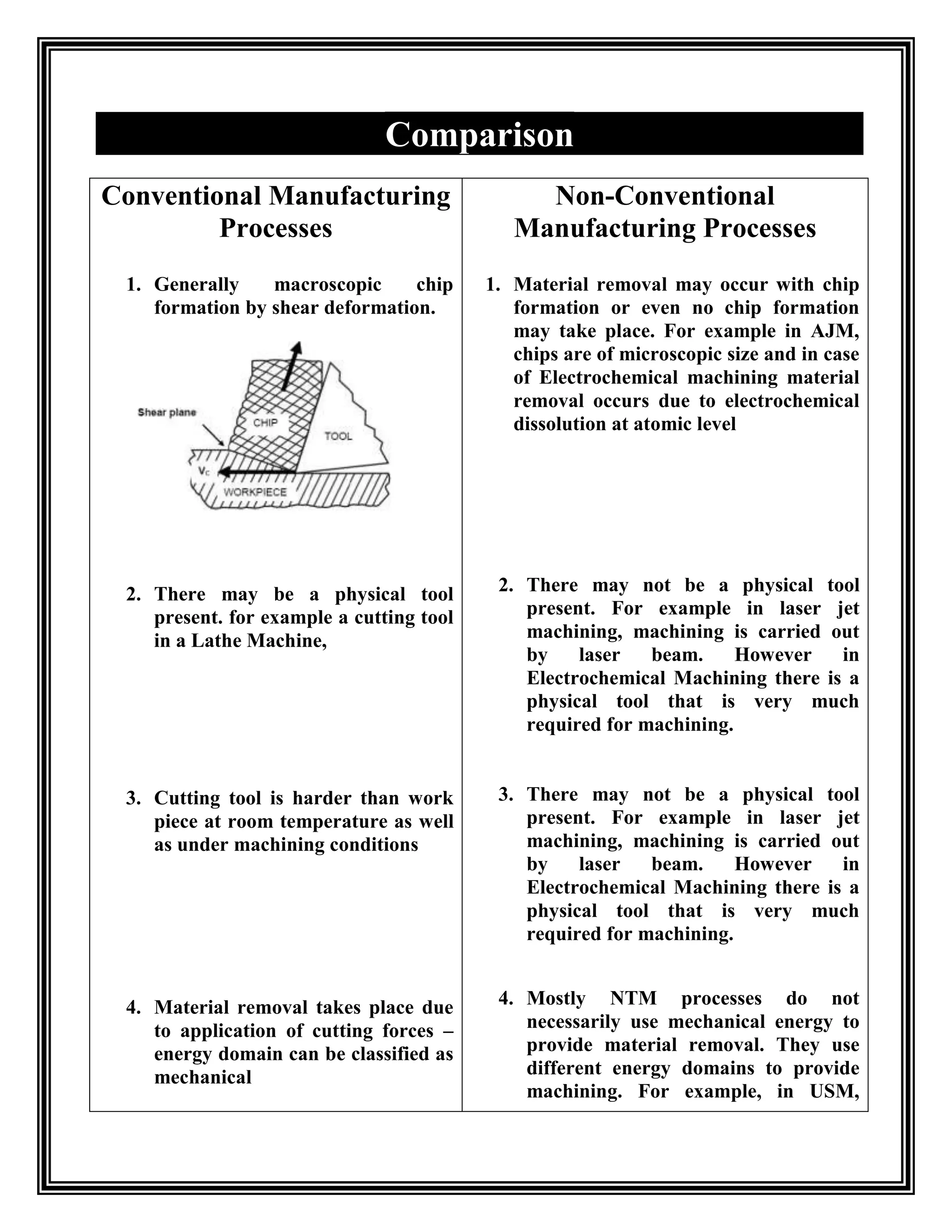

Conventional machining involves physically removing material from a workpiece using a harder cutting tool, typically through mechanical forces. Non-conventional machining utilizes other forms of energy like thermal, chemical, or electrical instead of mechanical forces and may not require physical contact or chip formation. While conventional machining can be used for most materials economically, non-conventional machining allows for higher precision machining of hard metals and complex parts but requires more advanced equipment and skilled operators.