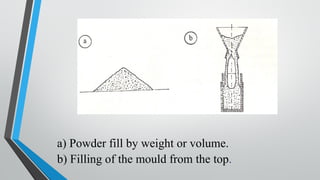

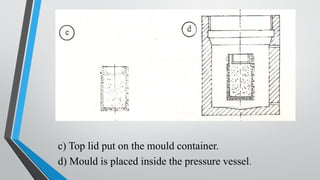

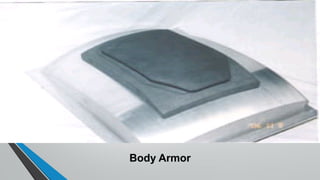

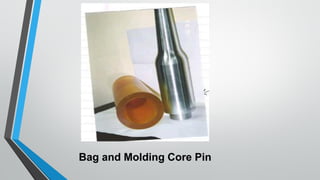

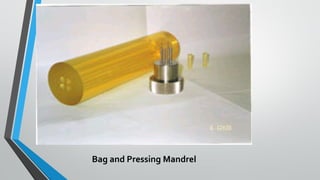

Cold isostatic pressing (CIP) is a technique where high pressure is applied uniformly to metal powder sealed in a flexible container. This compacts the powder to a density of 75-85% without die wall friction, resulting in a part with uniform density and no residual stresses. There are two methods - the wet bag process suited for batch production of complex parts, and the dry bag process using a fixed mold for mass production. CIP is used to make intricate or long shapes out of materials like titanium, tool steels, tungsten, and molybdenum powders.