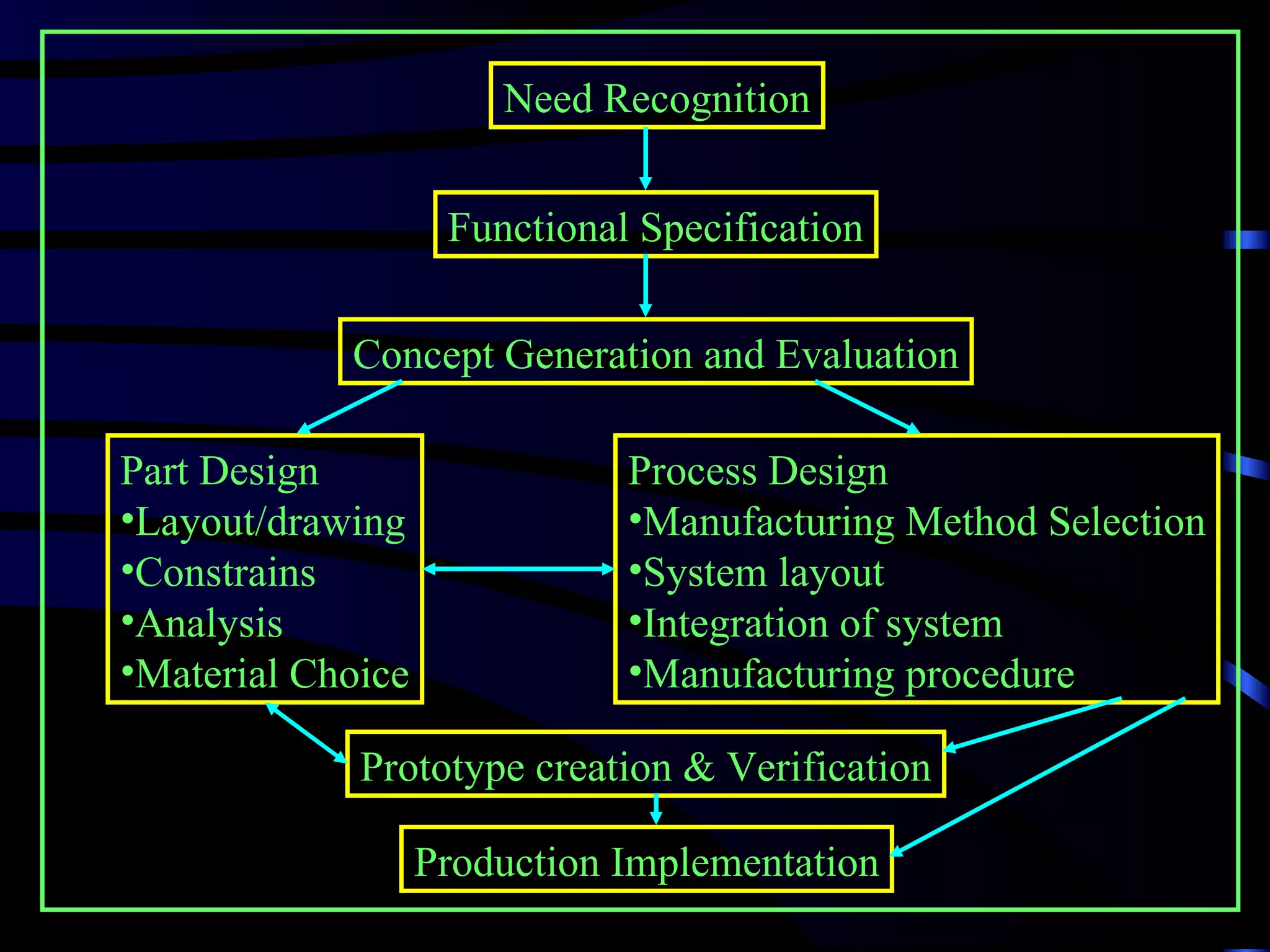

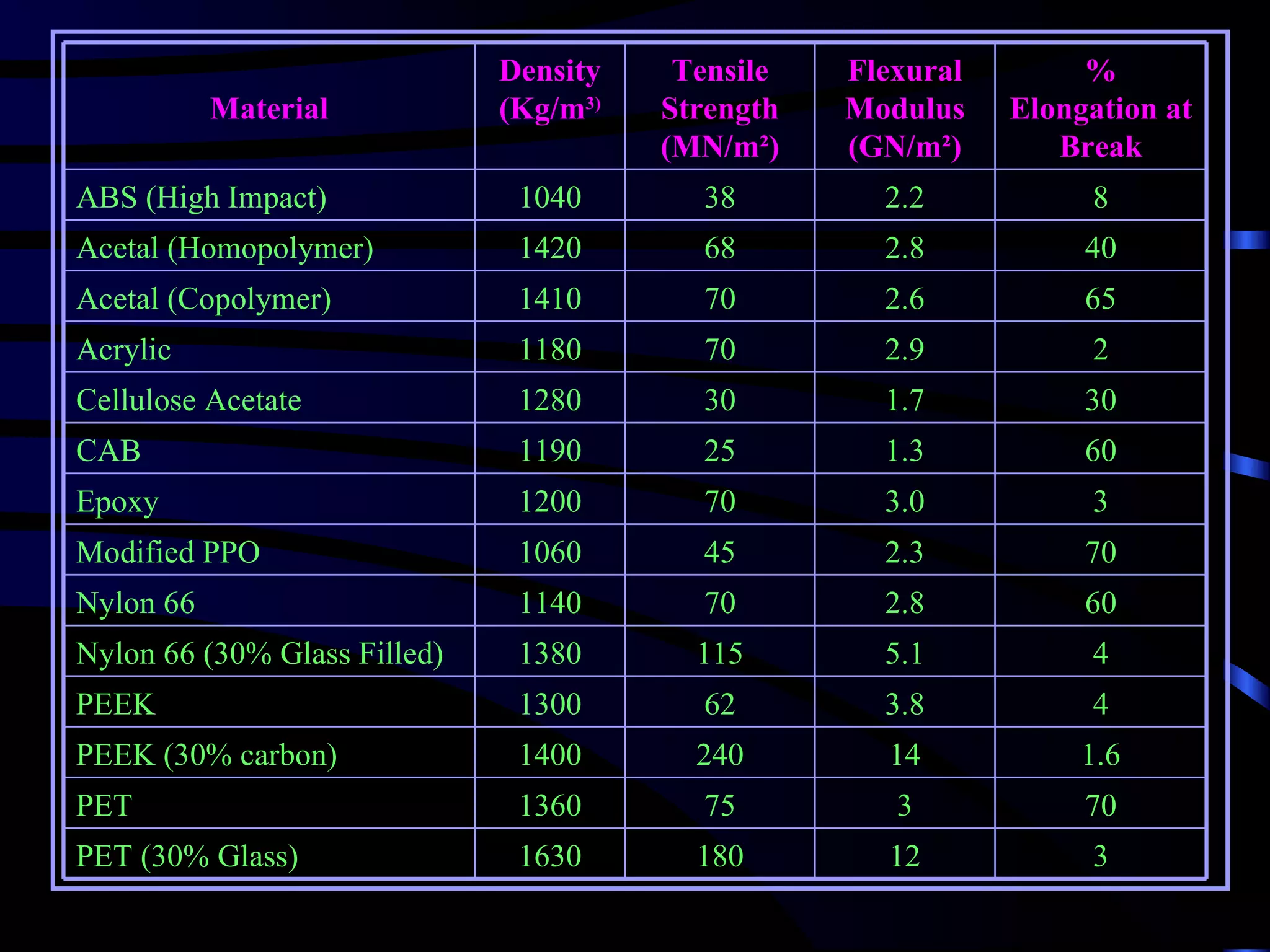

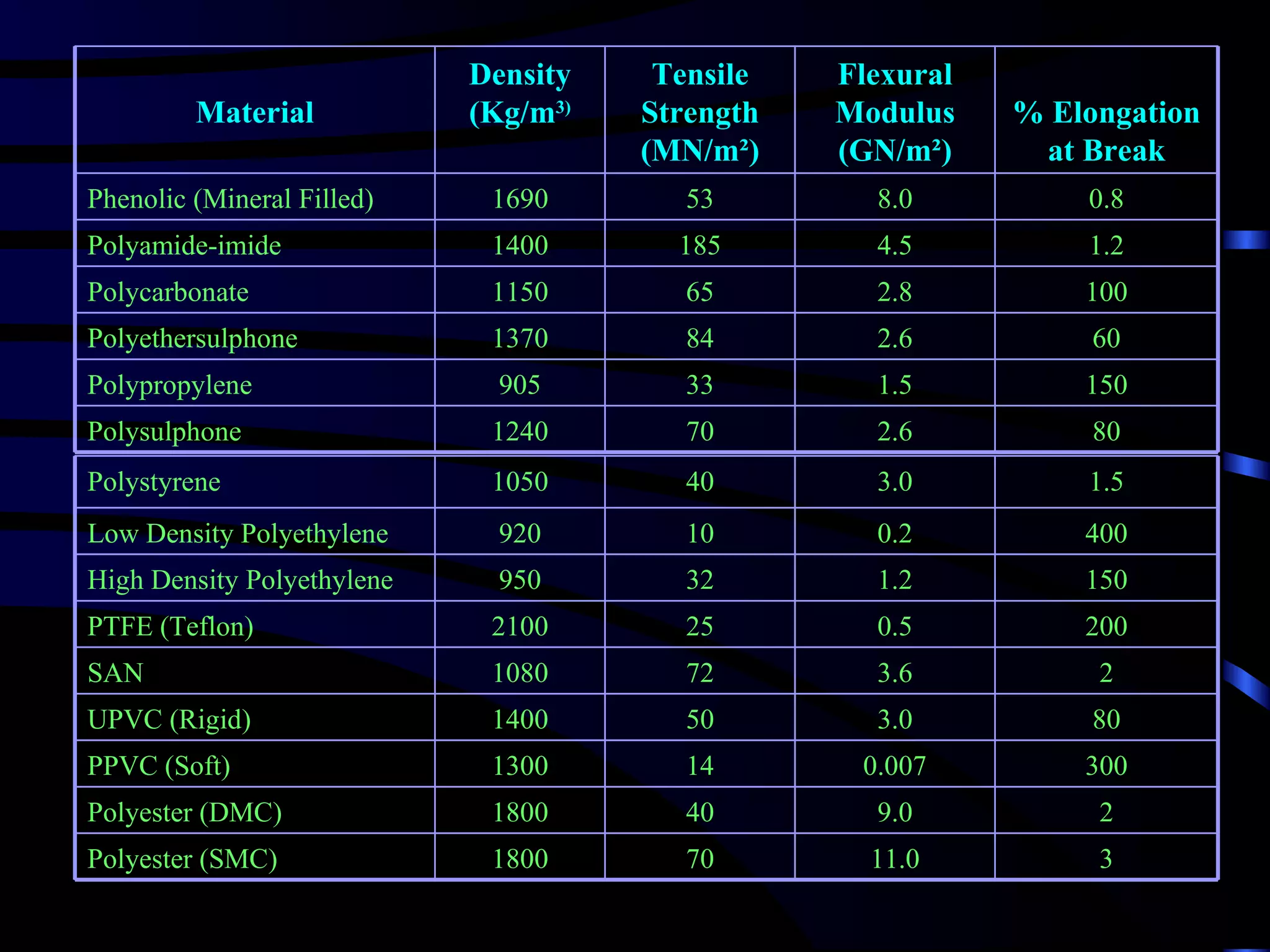

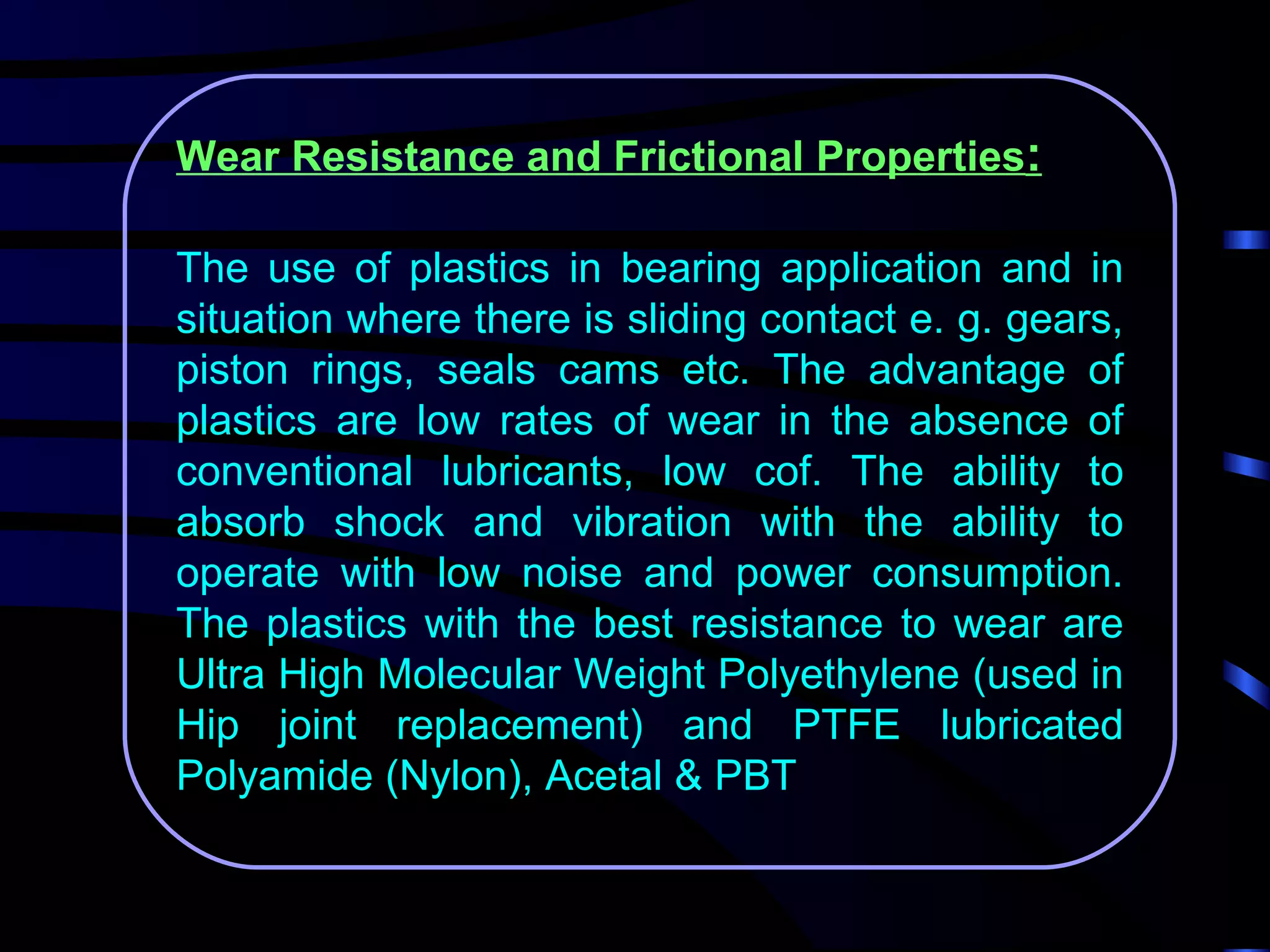

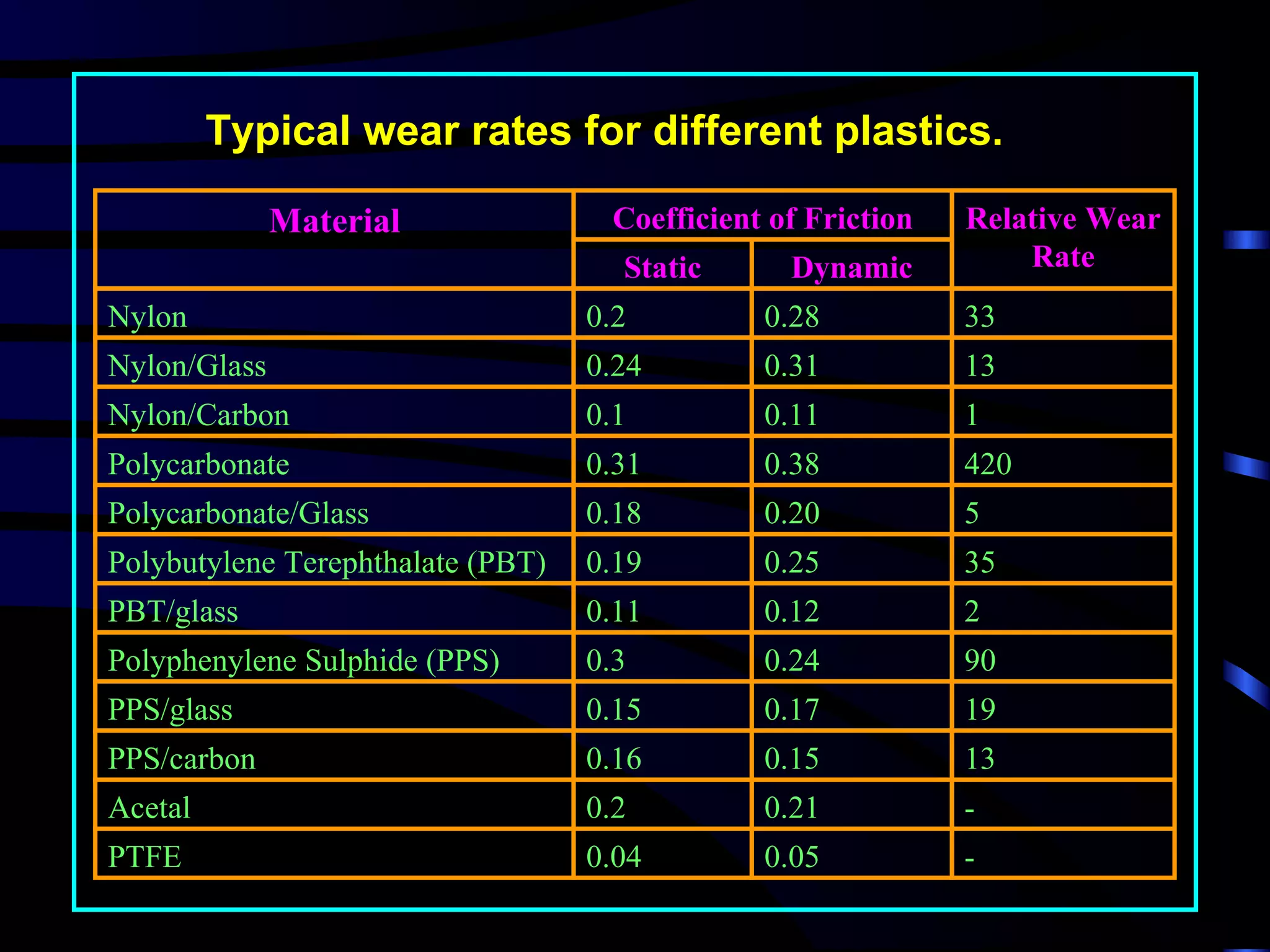

The document discusses material selection criteria for plastics in specific applications. It outlines the process of selecting plastics which involves defining the product purpose, assessing material properties, and considering factors like strength, temperature resistance, wear resistance, degradation resistance, and special properties. The document provides data on various plastic materials and their properties to guide selection. Key properties discussed include tensile strength, fatigue resistance, toughness, corrosion resistance, coefficient of friction, and electrical and thermal properties. Examples are given of applications suited for different plastics based on required characteristics.