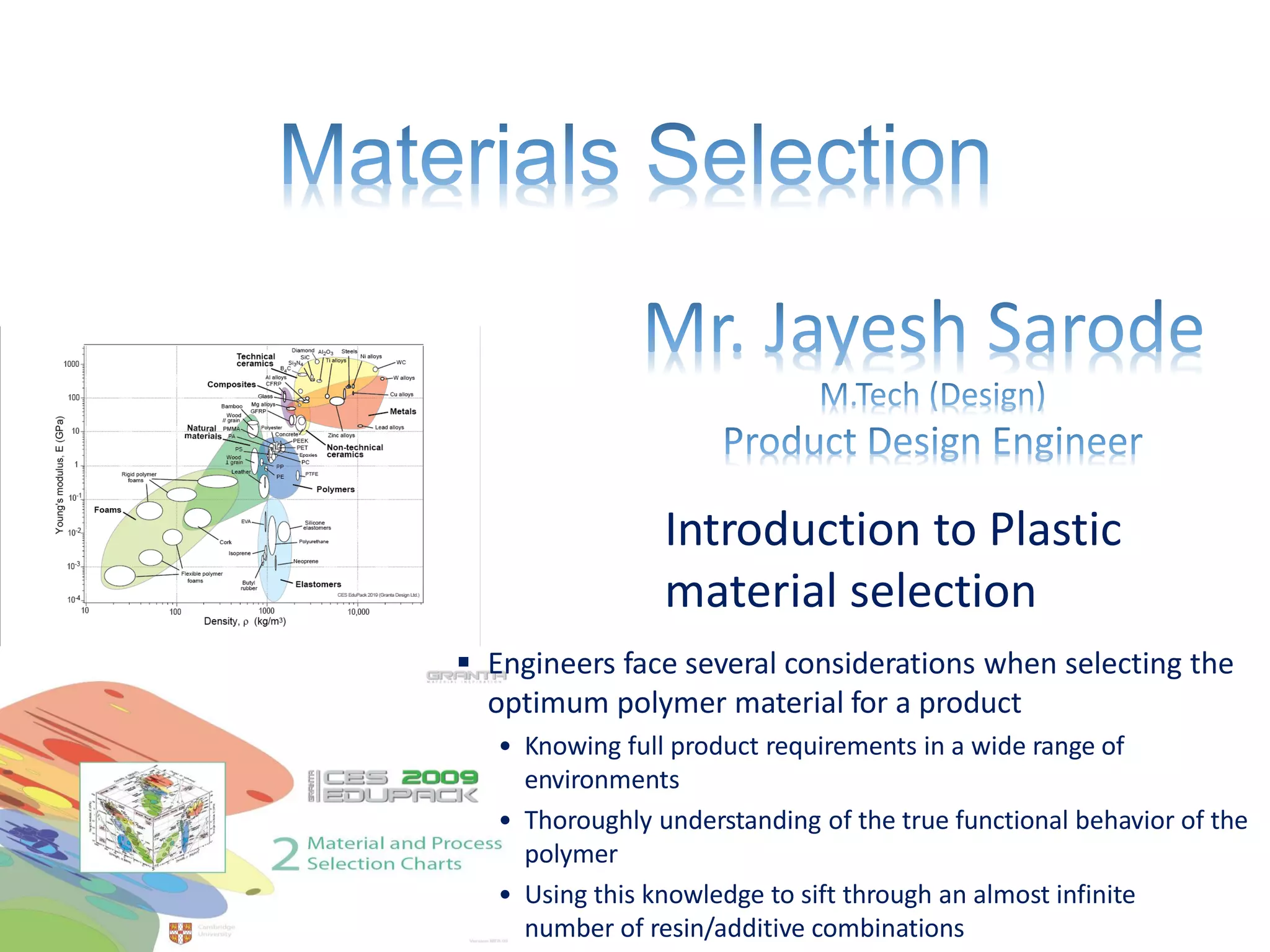

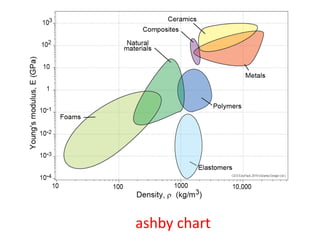

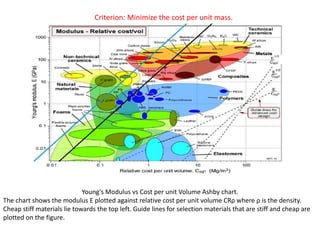

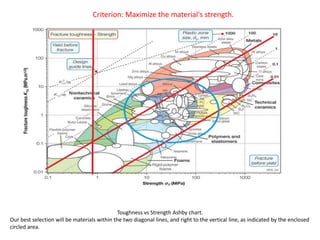

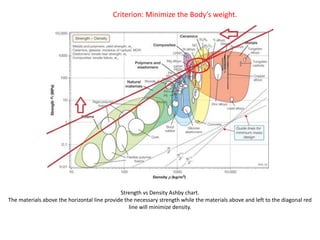

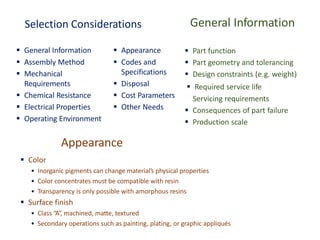

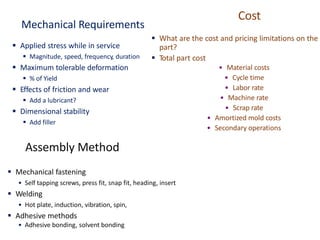

Engineers must consider various factors when selecting polymer materials, including product requirements, functional behavior, and cost versus performance metrics as illustrated by Ashby charts. Key considerations in material selection encompass mechanical properties, appearance, assembly methods, chemical resistance, and cost parameters. Material datasheets often lack comprehensive engineering data, emphasizing the importance of thorough analysis beyond marketing claims.