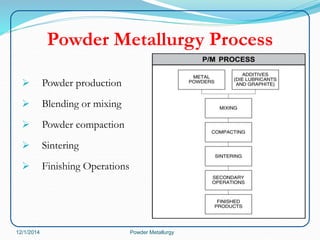

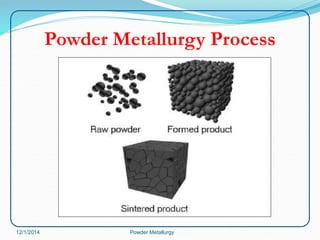

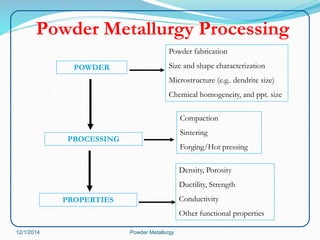

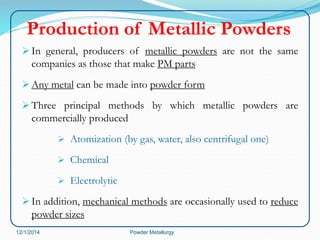

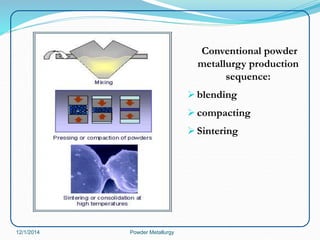

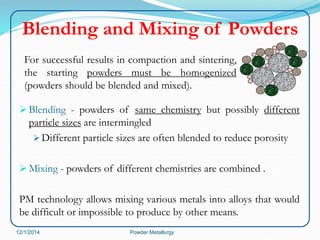

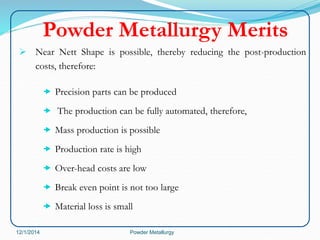

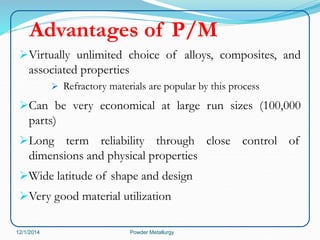

Powder metallurgy is a process that involves producing metal powders and compacting and sintering them to form finished parts. It allows for complex alloy compositions and near-net shape manufacturing, avoiding costly machining. The key steps are powder production, blending/mixing, compaction into a green compact, sintering to bond particles, and optional finishing. It offers advantages over casting and machining for net shape precision parts in large volumes.

![Powder Metallurgy

An important point that comes out :

The entire material need not be melted to fuse it.

The working temperature is well below the melting point of the

major constituent, making it a very suitable method to work

with refractory materials, such as: W, Mo, Ta, Nb, oxides,

carbides, etc.

It began with Platinum technology about 4 centuries ago… in

those days, Platinum, [MP = 1774°C], was "refractory", and

could not be melted.

12/1/2014 Powder Metallurgy](https://image.slidesharecdn.com/powdermetallurgy-141201022709-conversion-gate02/85/Powder-metallurgy-3-320.jpg)