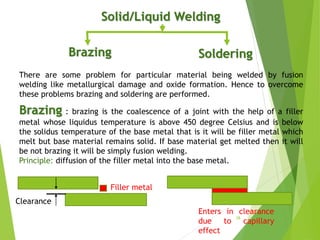

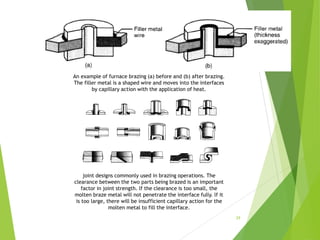

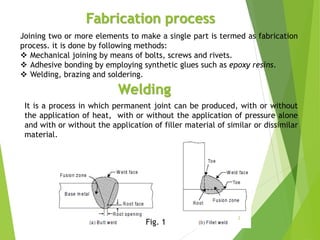

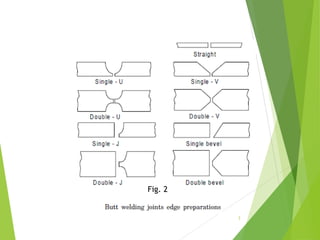

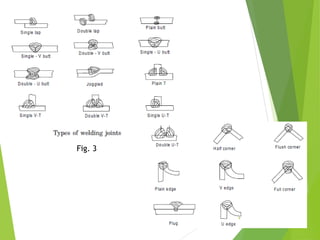

The document provides an extensive overview of welding practices, outlining various methods of joining materials, including mechanical joining, adhesive bonding, and multiple welding techniques such as oxy-fuel and arc welding. It discusses the advantages and disadvantages of welding, the types of equipment used, and the specific processes involved, such as gas tungsten arc and gas metal arc welding. Safety recommendations for gas welding and requirements for preparation, filler metals, and joint design in brazing and soldering are also covered.

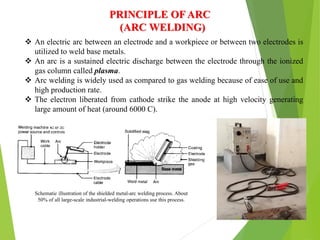

![[a] Direct current

straight polarity

(DCSP) or direct

current electrode

negative (DCEN)

[b] Direct current

reverse polarity

(DCRP) or direct

current electrode

positive (DCEP)

[c] Alternative

current (AC)

Electrode is ‘–ve’ and

workpiece is ‘+ve’.

2/3 rd heat on w/p

and 1/3 rd heat on

electrode.

Used for high

thickness w/p and

high melting point

material.

Depth of penetration

is more.

weld deposition rate

and welding speed will

be low.

Electrode is ‘+ve’ and

workpiece is ‘-ve’.

1/3 rd heat on w/p

and 2/3 rd heat on

electrode.

Used for low thickness

w/p and low melting

point material.

Depth of penetration

is less.

weld deposition rate

and welding speed will

be more.

50 % heat on w/p and

50 % heat on

electrode.

Used for medium

thickness w/p and

intrmediate melting

point material.

Depth of penetration

is intermediate.

weld deposition rate

and welding speed will

be intermediate.

The effect of polarity and current type on

weld beads: (a) DC current with straight polarity; (b) DC

current with reverse polarity; (c) AC current.

21](https://image.slidesharecdn.com/welding-200401100655/85/Welding-21-320.jpg)