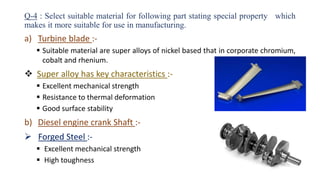

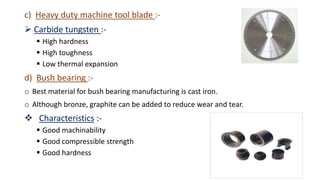

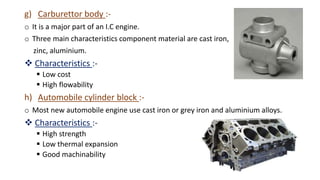

The document discusses material selection criteria for machine element design, highlighting factors like availability, cost, mechanical properties, and manufacturing considerations. It provides examples of commonly used engineering materials such as cast iron, alloy steel, plastics, and aluminum alloys, along with their properties and applications. Additionally, it outlines suitable materials for specific machine parts based on their mechanical requirements.

![Gandhinagar Institute of Technology

Subject :- Design of machine Element

MECHANICAL ENGINEERING

5th - B : 2

Material selection

– Malaviya Bhautik [130120119094]

Pavan Narkhede [130120119111]

Darshit Panchal [130120119114]

:

Prof. Amit Patel](https://image.slidesharecdn.com/dme-exercise-materialselection-151231102702/75/selection-of-material-1-2048.jpg)