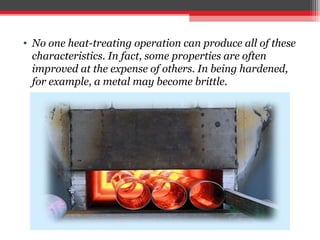

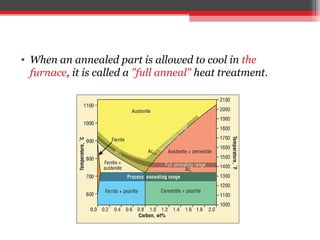

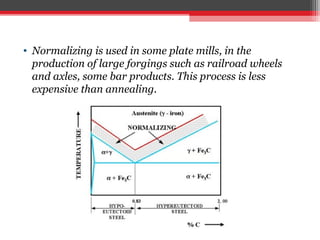

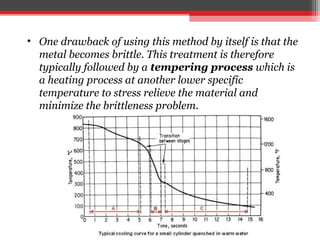

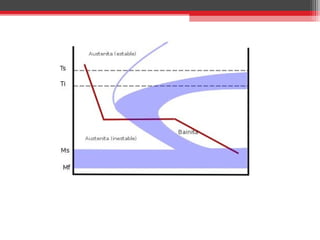

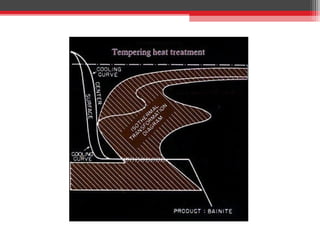

The document provides an overview of various heat treatment processes used in metals, aiming to alter mechanical properties for improved serviceability. Key processes discussed include annealing, normalizing, quenching, case hardening, and tempering, each with specific purposes and outcomes. The techniques enhance characteristics such as strength, wear resistance, and ductility while acknowledging trade-offs between hardness and brittleness.