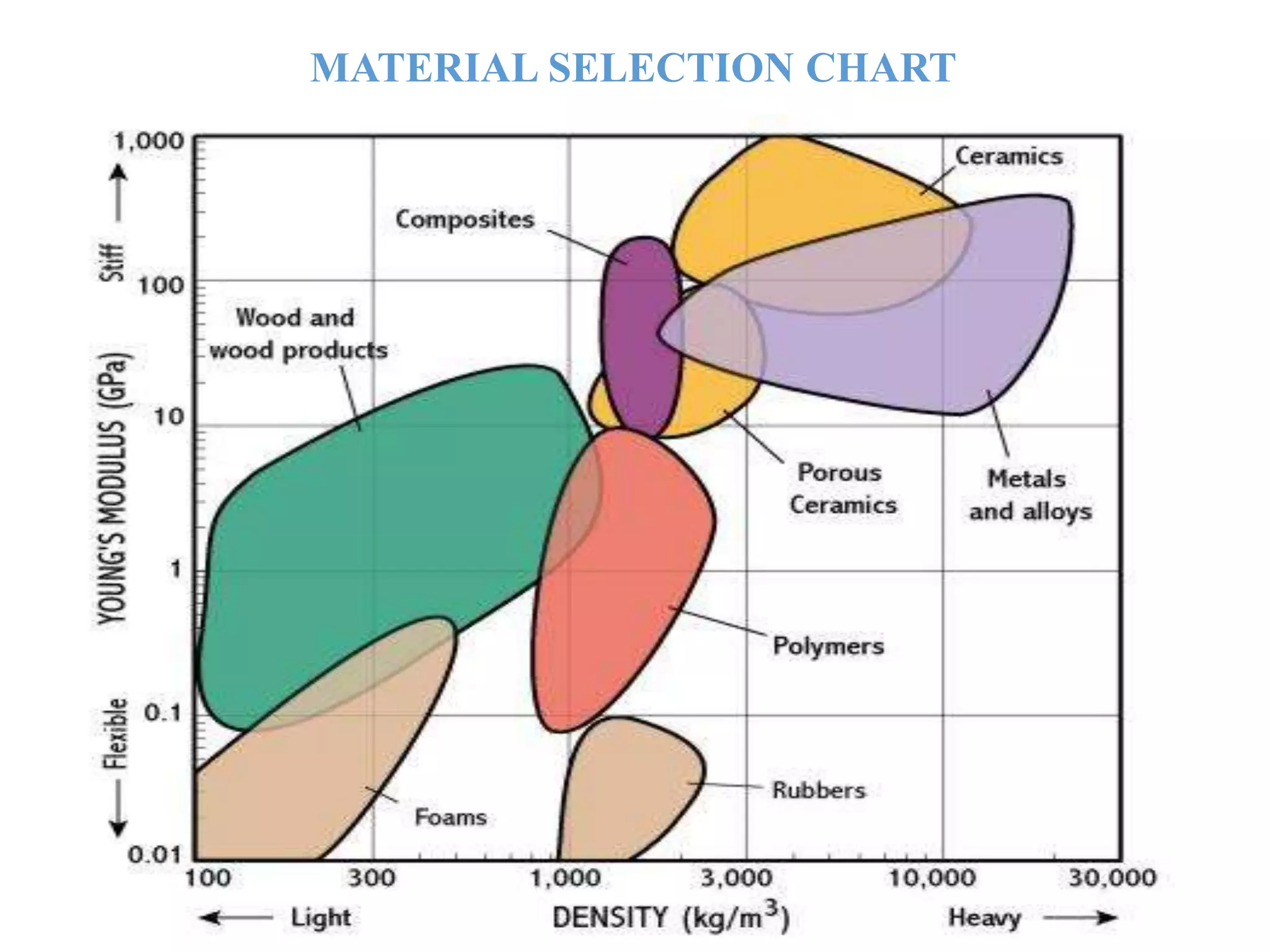

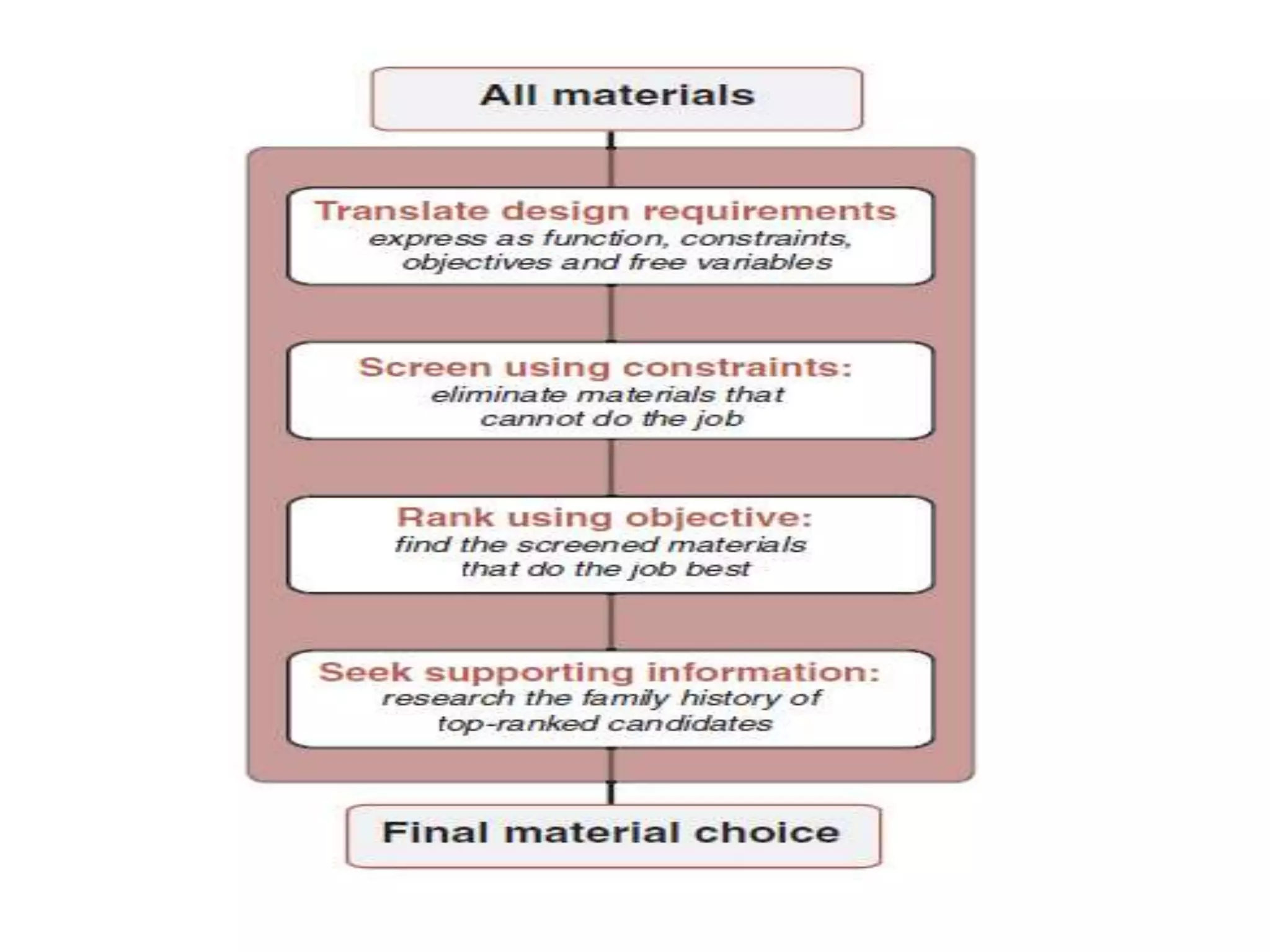

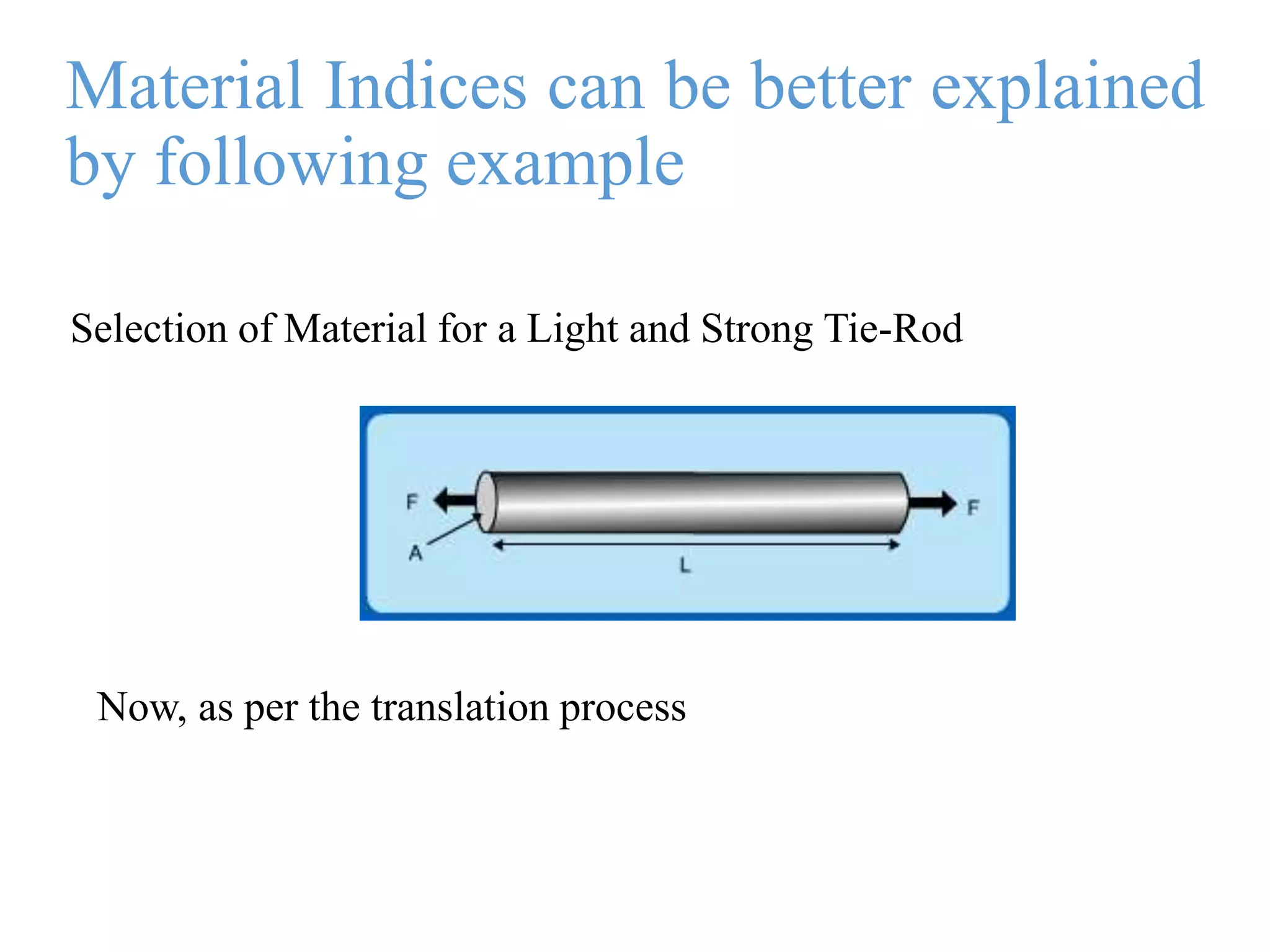

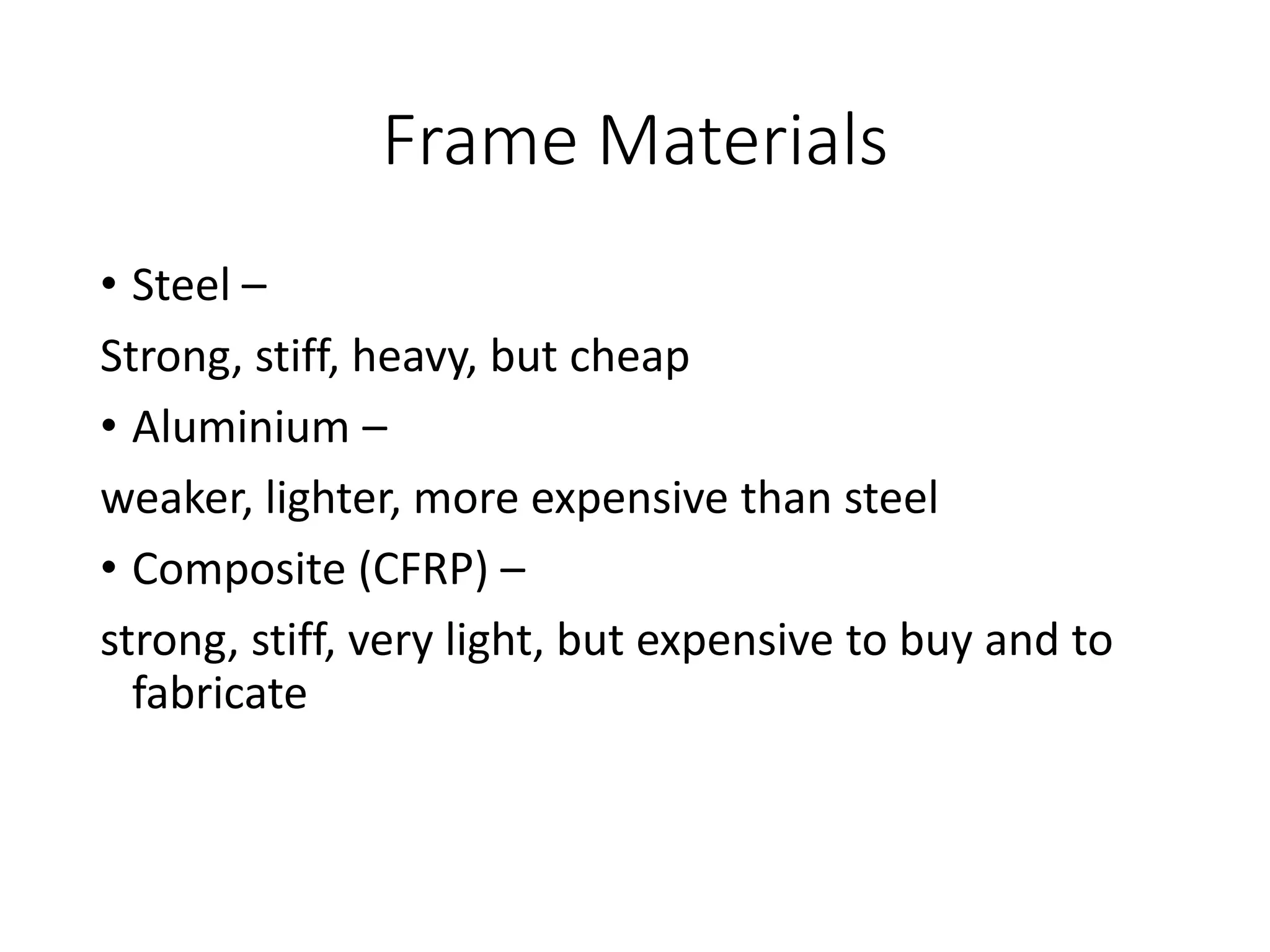

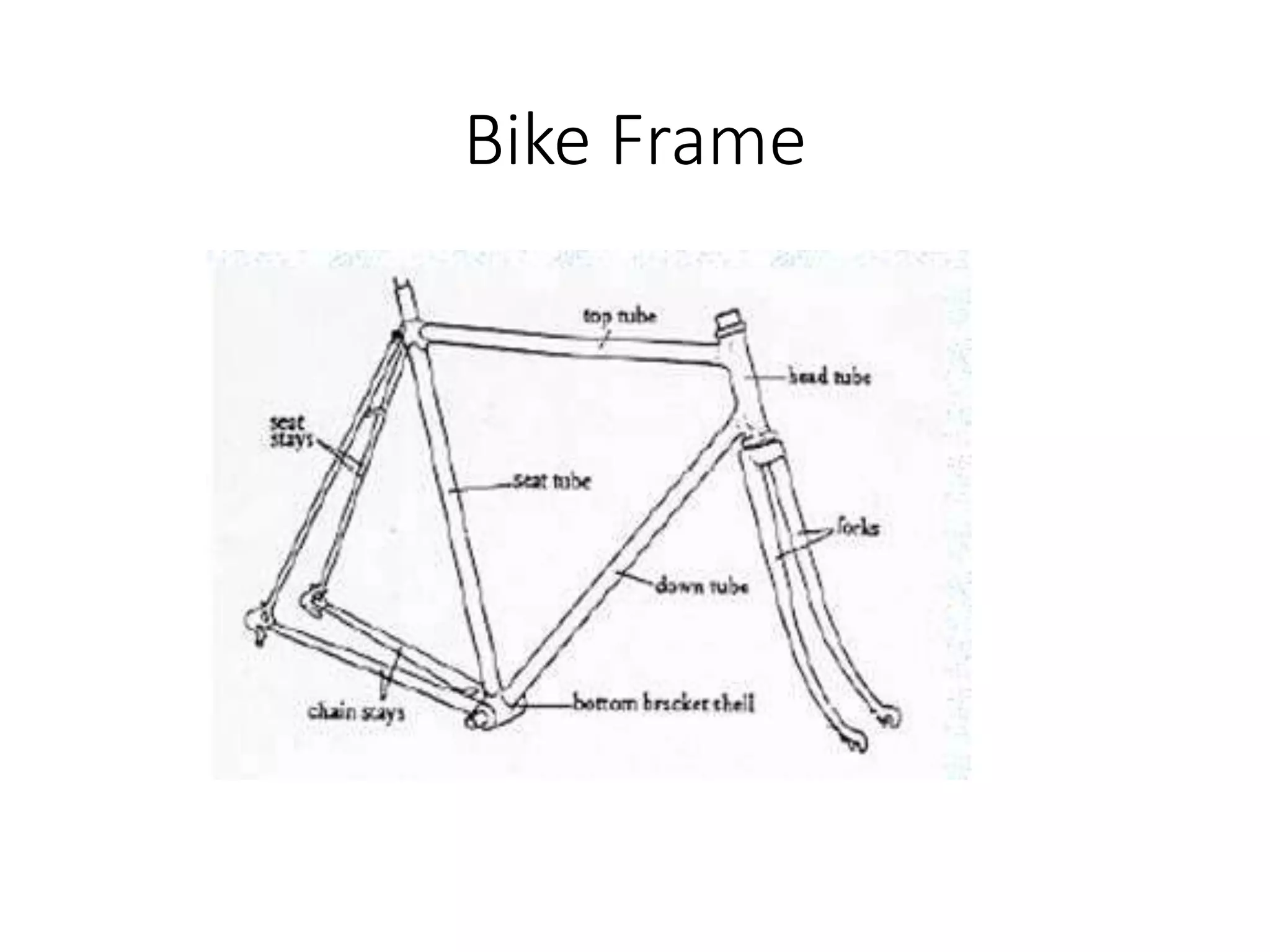

This document discusses material selection for manufacturing. It begins by stating that material selection is an important step in product design to minimize costs while meeting performance goals. It then discusses using material selection charts to compare properties like stiffness and density to help choose appropriate materials. The document outlines a four step strategy for material selection: 1) translation to identify design requirements, 2) screening out unsuitable materials, 3) ranking remaining candidates, and 4) seeking additional supporting information. Key material properties like function, constraints, and objectives are defined. Case studies on selecting materials for a bike and drink container are also provided.