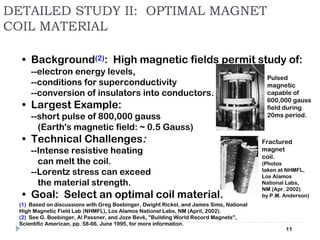

This document discusses materials selection and design considerations. It addresses selecting materials based on price, availability, and optimal performance for applications like shafts under torsion, bars under tension, and plates under bending. Examples are provided on maximizing performance indices or minimizing cost indices for strong, light members and for selecting optimal materials for magnet coils based on withstanding Lorentz stress and resistive heating. Recycled materials can significantly reduce energy use compared to processing raw materials.