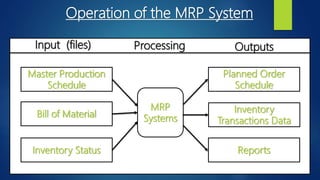

MRP is a materials requirements planning system developed in 1964 to help manufacturing companies manage inventory. It uses a master production schedule, bill of materials, and inventory records as inputs to determine when to release new orders and reschedule open orders. The objectives of MRP are to ensure materials and products are available when needed, maintain low inventory levels, and plan manufacturing, delivery, and purchasing activities. It operates by processing input files through the MRP system to generate outputs like planned order schedules. Potential issues include lot sizing, safety stock, scrap allowance, and updating inaccurate files.