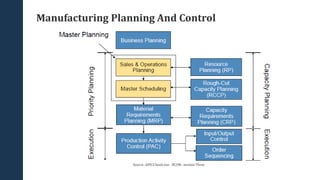

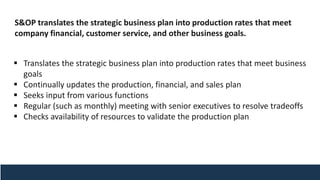

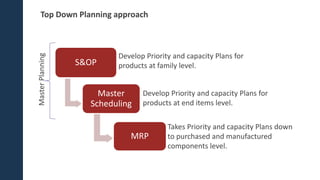

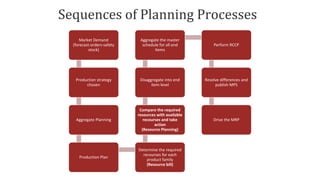

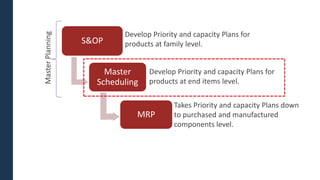

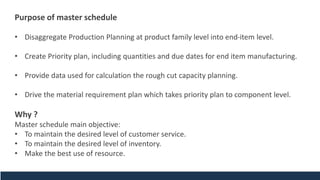

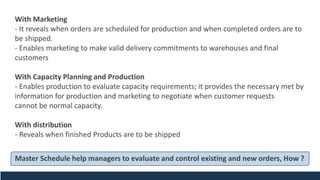

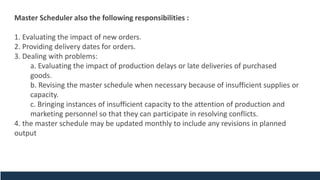

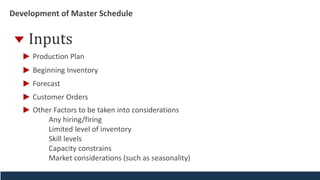

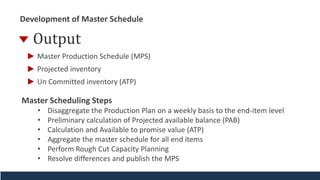

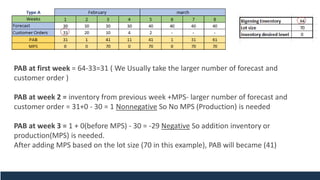

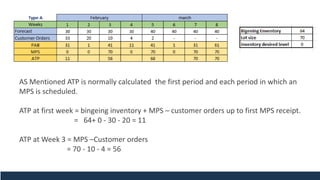

The document discusses production planning processes including sales and operations planning (S&OP), master scheduling, and material requirements planning (MRP). S&OP translates strategic business plans into production rates to meet goals. Master scheduling develops priority and capacity plans for products at the end item level. It disaggregates aggregate production plans and provides data for rough cut capacity planning (RCCP) and material requirements planning (MRP). RCCP ensures master schedules are feasible by checking capacity against demand. [END SUMMARY]