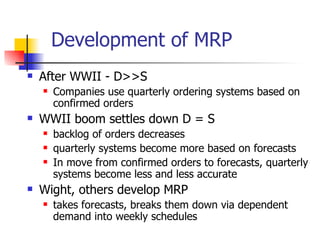

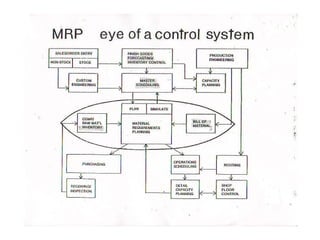

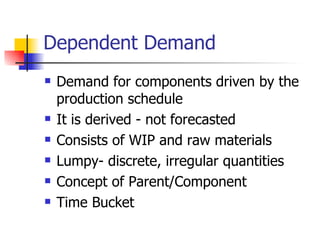

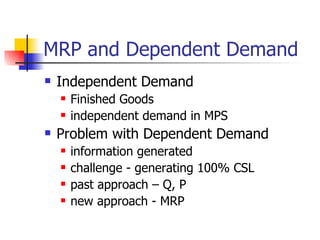

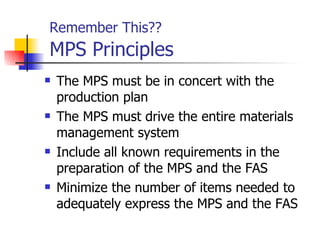

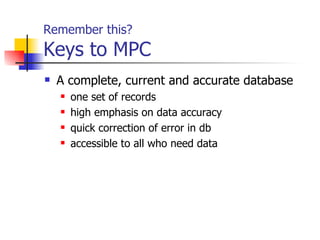

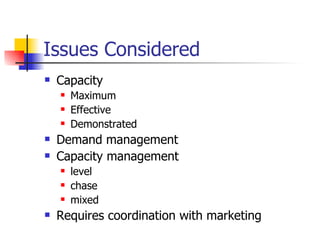

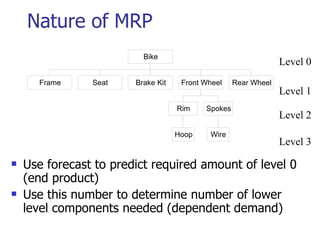

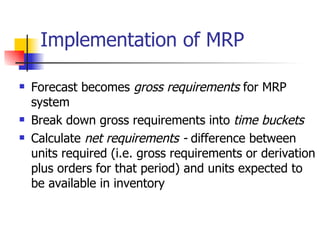

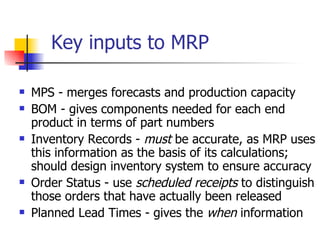

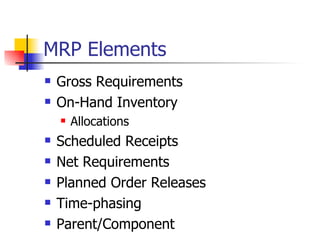

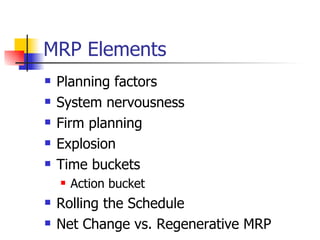

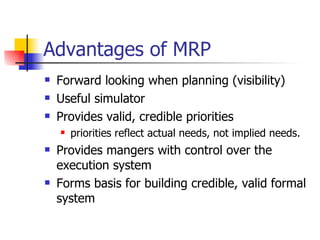

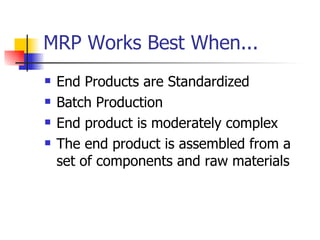

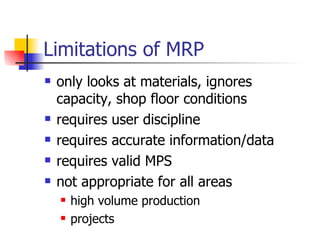

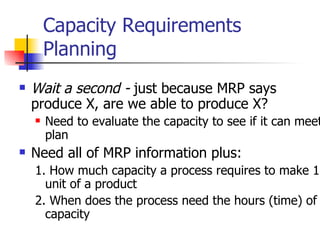

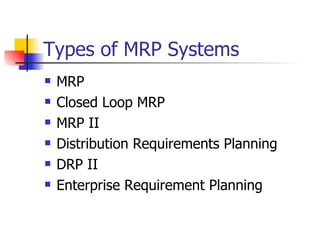

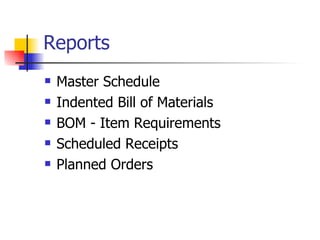

The document discusses materials requirements planning (MRP), which coordinates the flow of components and inputs through the production process. MRP was developed after World War II to improve upon quarterly ordering systems as demand became more based on forecasts rather than confirmed orders. It takes production forecasts and breaks them down into weekly schedules using a bill of materials to determine dependent demand for components. MRP provides schedules and priorities to help manage inventory levels and avoid stockouts. It requires accurate data on master production schedules, bills of materials, inventory levels, and order status.