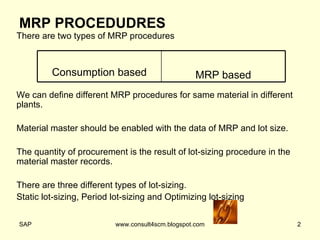

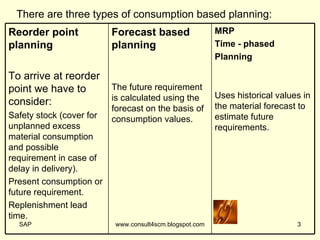

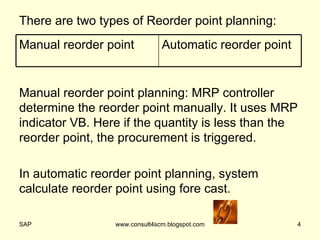

MRP (Material Requirements Planning) procedures involve defining different MRP procedures for materials in different plants and enabling the material master with MRP and lot size data. There are three types of lot sizing - static, period, and optimizing - that determine order quantities. MRP generates procurement proposals like planned production orders and purchase requisitions to ensure material availability based on consumption, forecast, or reorder point planning. Main functions of MRP are to ensure material availability and generate procurement proposals for purchasing and production.