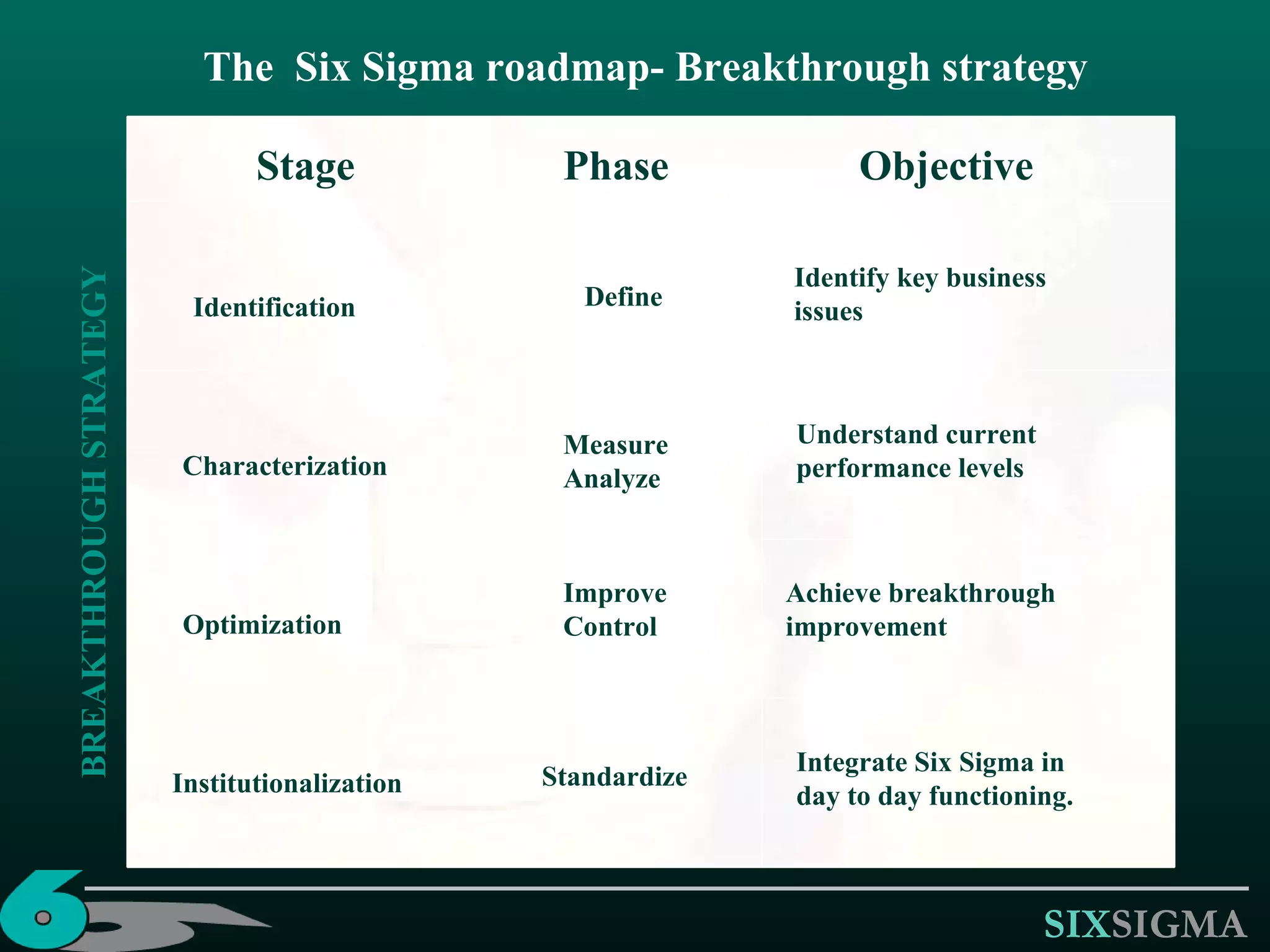

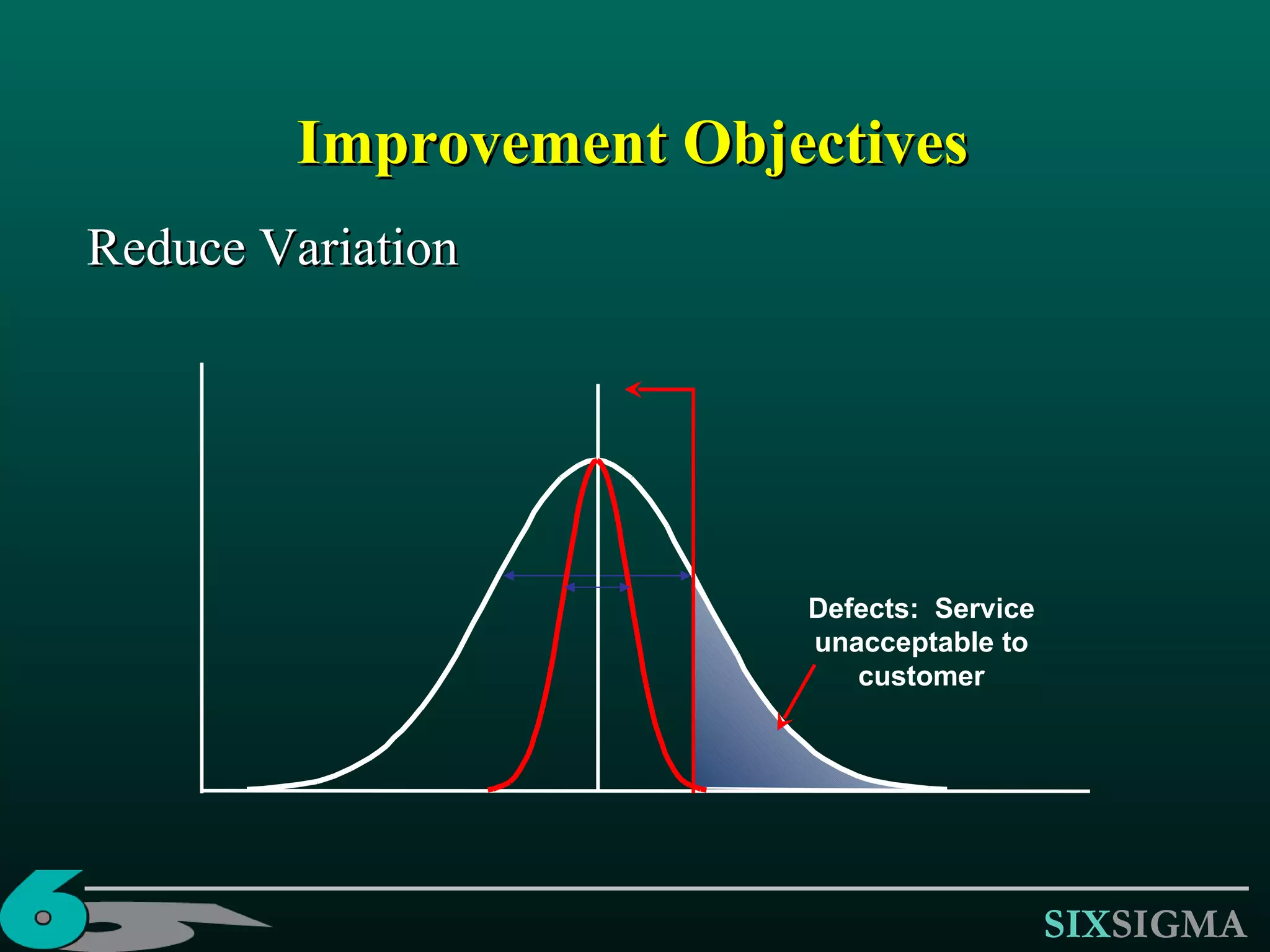

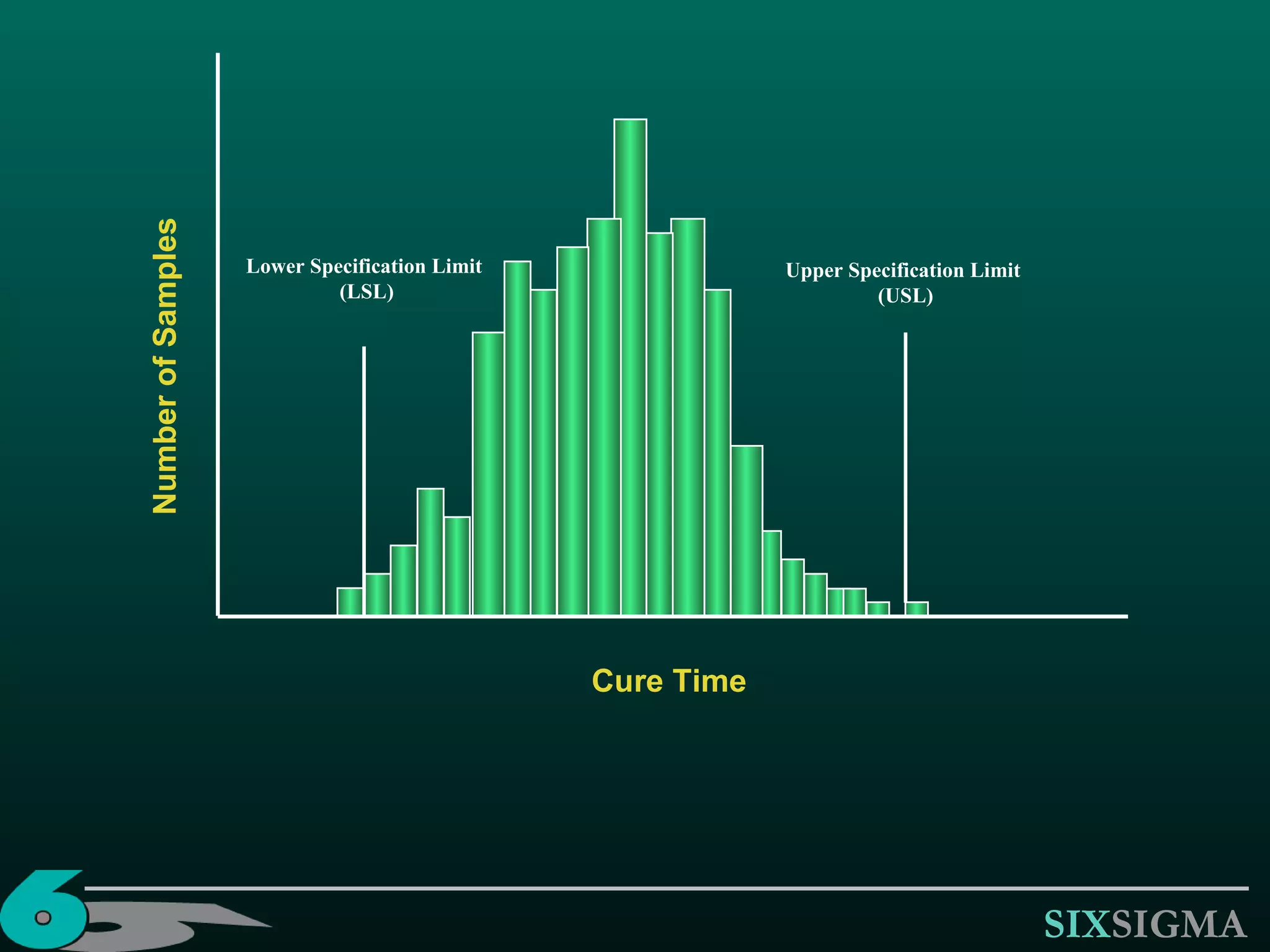

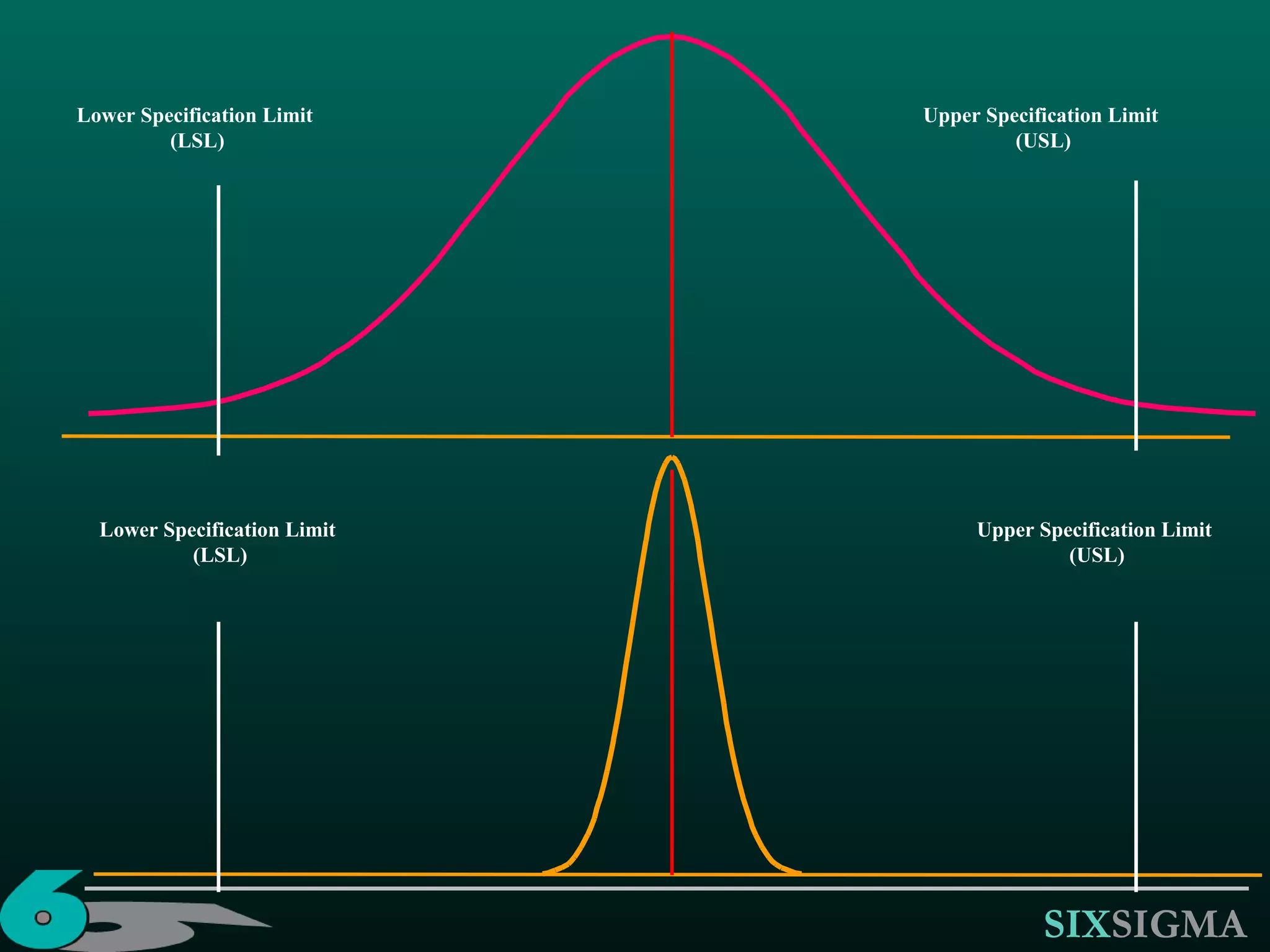

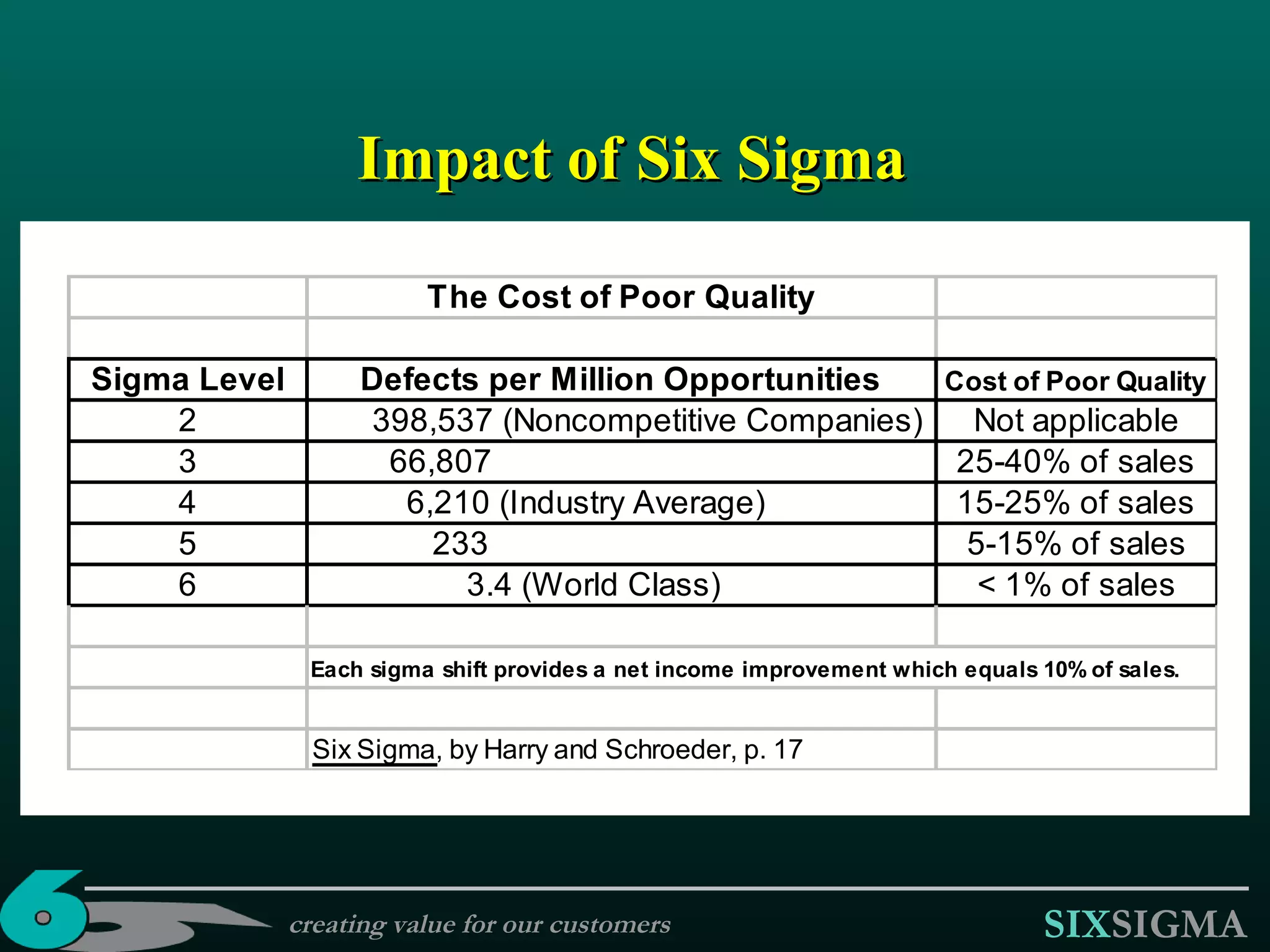

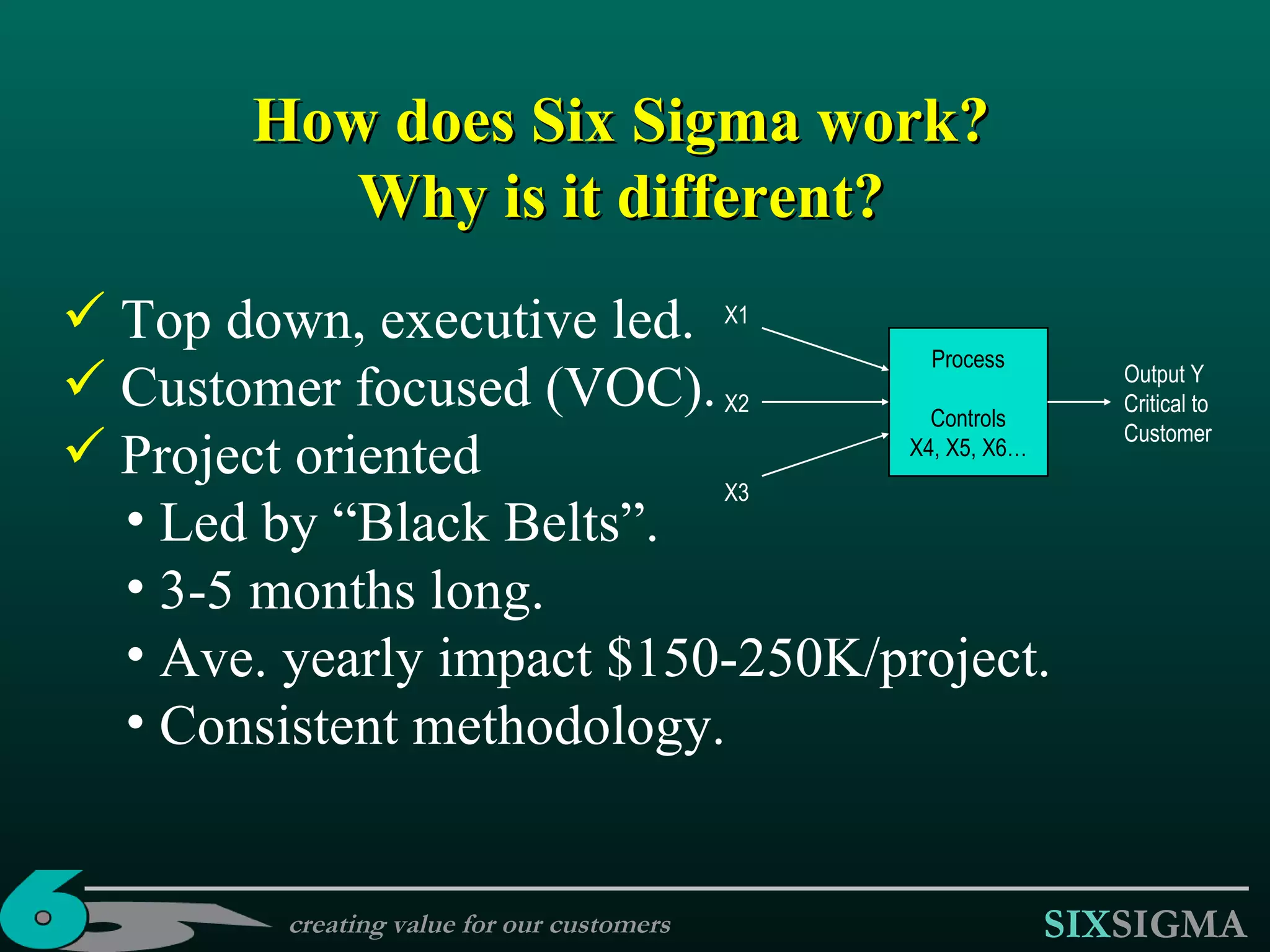

Six Sigma is a methodology for process improvement that aims to reduce defects to 3.4 defects per million opportunities. It is driven by close understanding of customer needs and uses statistical analysis to improve processes. The Six Sigma methodology involves defining problems, measuring key aspects, analyzing causes of defects, improving processes, and controlling improvements. The goal is to achieve a high level of quality that creates value for customers through eliminating waste and defects.