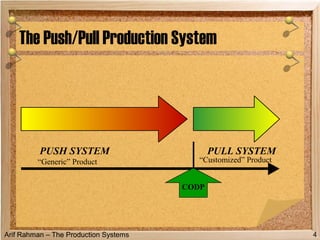

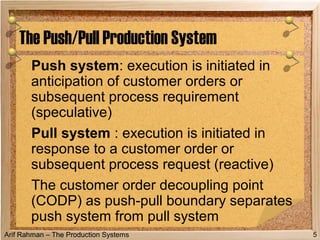

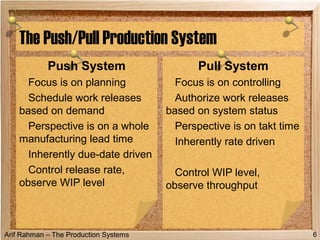

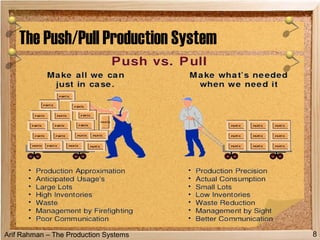

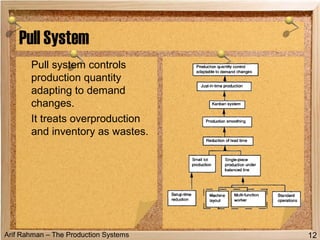

The document discusses push and pull production systems. It focuses on explaining the pull system and Kanban methodology. Some key points:

- A pull system is a production system where a downstream workstation pulls units from upstream as needed, rather than units being continuously pushed downstream.

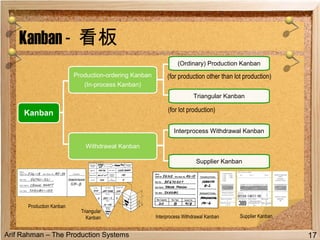

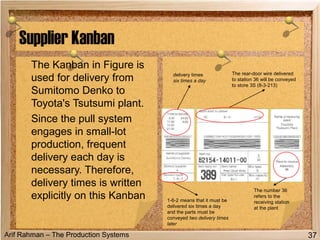

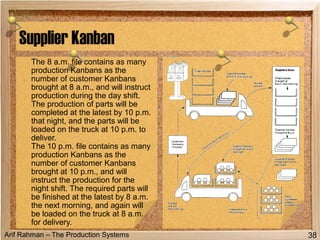

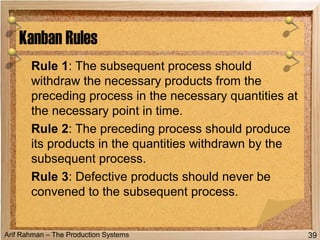

- Kanban is a signaling system used in pull production to trigger replenishment of units. Withdrawal Kanbans are sent from downstream to upstream and trigger production of replacement units.

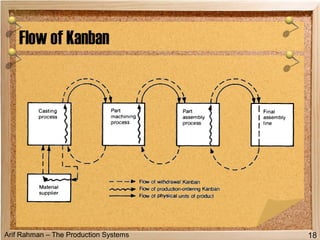

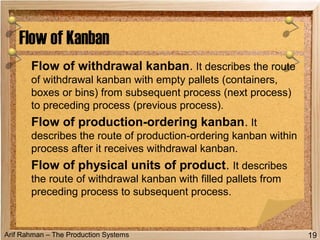

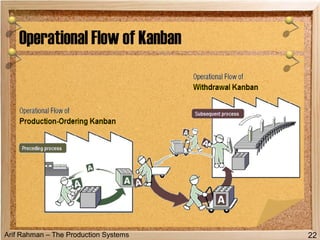

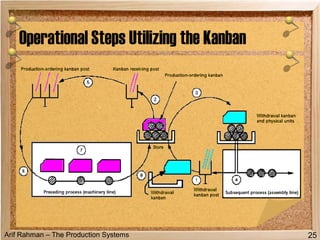

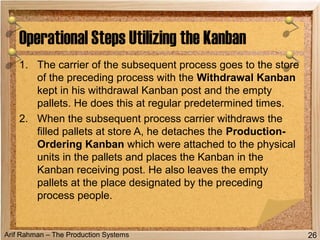

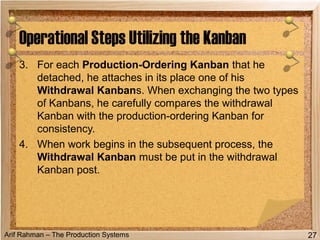

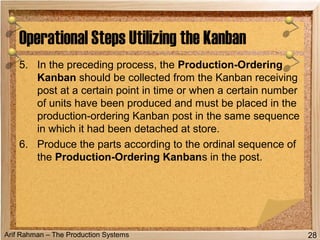

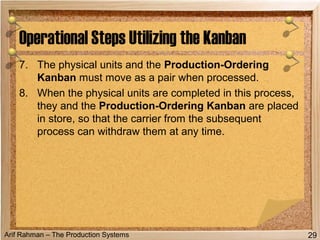

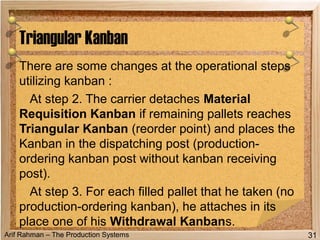

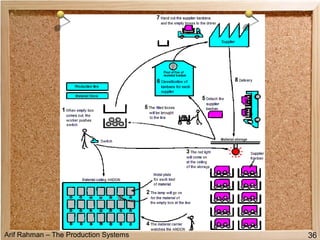

- The operational flow of Kanban involves carriers exchanging withdrawal Kanbans for production-ordering Kanbans between processes, and attaching the Kanbans to units as they move through the system.

![Arif Rahman – The Production Systems

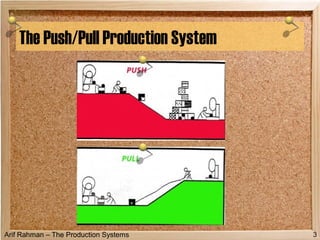

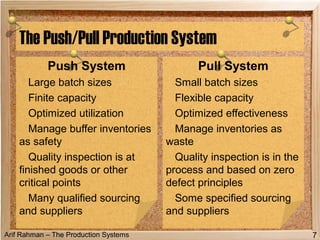

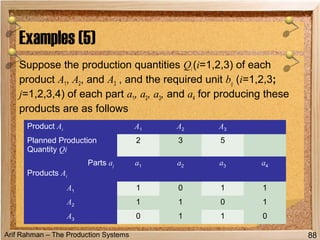

Then, the total necessary quantity (Nj) of the part aj

(j=1,2,3,4) for producing all products Ai(i=1,2,3) can be

computed as follows:

the total production quantity of all products Ai(i=1,2,3) :

and

untuk (j=1,2,3,4)

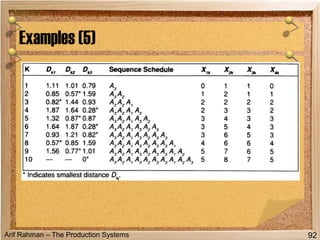

Examples (5)

89

[ ] [ ]5785

0110

1011

1101

532

]][[][

=

=

= ijij bQN

10532

3

1

=++=∑=i

iQ [ ]10/510/710/810/5]/[ =QN j](https://image.slidesharecdn.com/13pullsystem-190208153118/85/13-pull-system-89-320.jpg)

![Arif Rahman – The Production Systems

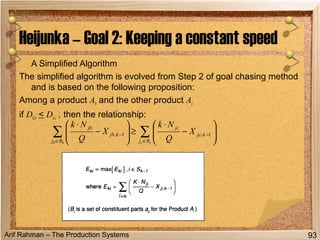

Applying the values of [Nj/Q] and [bij] to the formula in step 2

of the above algorithm,

When K = 1, the distances Dki can be computed as follows:

Thus, D1,i* = min {1.11, 1.01, 0.79) = 0.79

Sequence A3

Xjk = Xjk-1 + b3j = [0 1 1 0]

Examples (5)

90

( ) ( ) ( ) ( ) 11.110100010,1for

2

10

512

10

712

10

812

10

51

1,1 =−−+−−+−−+−−== ××××

Di

( ) ( ) ( ) ( ) 01.110001010,2for

2

10

512

10

712

10

812

10

51

2,1 =−−+−−+−−+−−== ××××

Di

( ) ( ) ( ) ( ) 79.000101000,3for

2

10

512

10

712

10

812

10

51

3,1 =−−+−−+−−+−−== ××××

Di](https://image.slidesharecdn.com/13pullsystem-190208153118/85/13-pull-system-90-320.jpg)

![Arif Rahman – The Production Systems

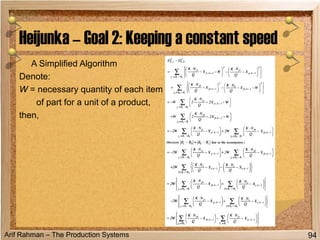

When K = 2, the distances Dki can be computed as follows:

Thus, D2,i* = min {0.85, 0.57, 1.59) = 0.57

Sequence A3 A2

Xjk = Xjk-1 + b2j = [1 2 1 1]

Examples (5)

91

( ) ( ) ( ) ( ) 85.010110110,1for

2

10

522

10

722

10

822

10

52

1,2 =−−+−−+−−+−−== ××××

Di

( ) ( ) ( ) ( ) 57.010011110,2for

2

10

522

10

722

10

822

10

52

2,2 =−−+−−+−−+−−== ××××

Di

( ) ( ) ( ) ( ) 59.100111100,3for

2

10

522

10

722

10

822

10

52

3,2 =−−+−−+−−+−−== ××××

Di](https://image.slidesharecdn.com/13pullsystem-190208153118/85/13-pull-system-91-320.jpg)