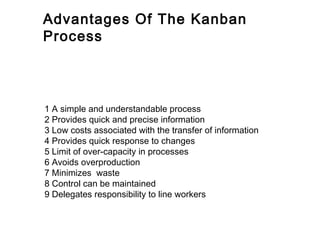

The Kanban system is a Japanese production system that uses visual signals like cards and containers to control the flow of parts between workstations. Only the necessary components are delivered from suppliers to the production line as needed to avoid excess storage. Each workstation only produces enough parts to fill an empty container before stopping in order to limit inventory levels in the process.