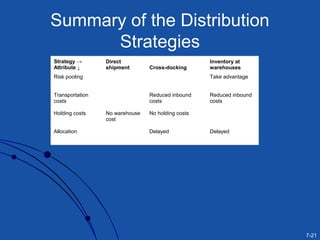

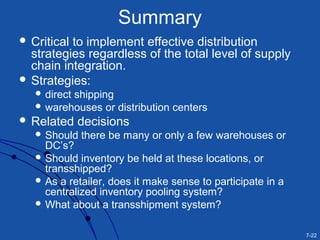

The document discusses various distribution strategies including direct shipment, intermediate inventory storage, traditional warehousing, cross-docking, and centralized pooled systems. Direct shipment reduces costs but removes risk pooling benefits. Intermediate storage uses warehouses and distribution centers to hold or transfer inventory using strategies like traditional warehousing, cross-docking, and centralized pooling. The optimal strategy depends on factors like costs, demand variability, and service level requirements.