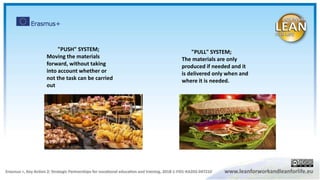

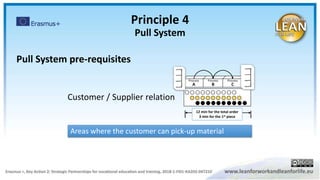

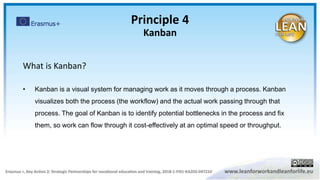

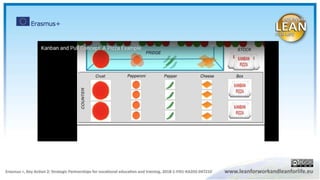

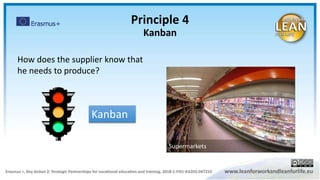

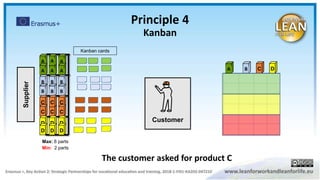

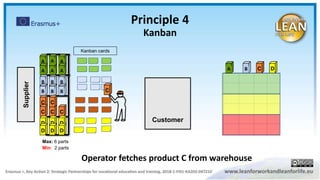

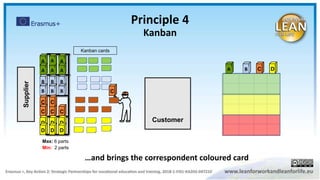

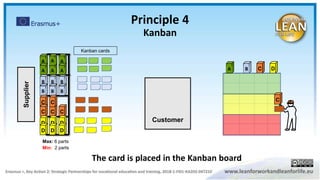

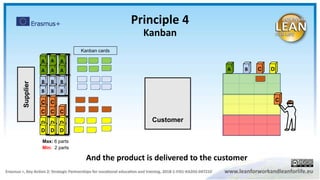

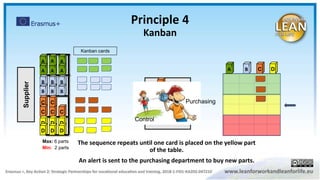

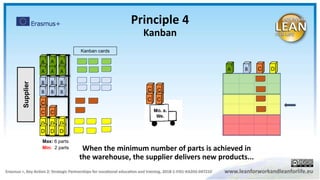

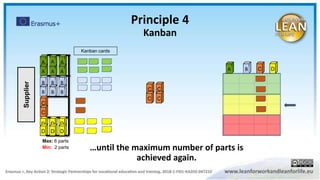

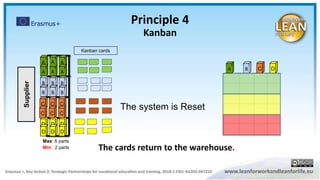

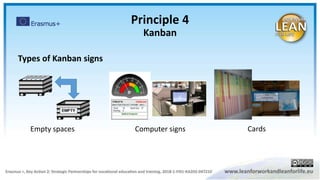

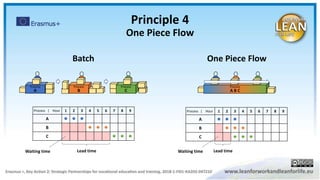

This document provides an overview of pull production in Lean manufacturing. It discusses the differences between push and pull systems, and how pull systems avoid waste by only producing what is needed. Kanban cards and one-piece flow are introduced as tools to implement a pull system. Kanban cards allow the customer to signal production needs and regulate workflow between processes. One-piece flow reduces waste by processing one item at a time through each process. Examples of pull systems in supermarkets and Kanban card usage in a supply chain are described. The benefits of pull systems like reduced inventory and self-regulating production schedules are also summarized.