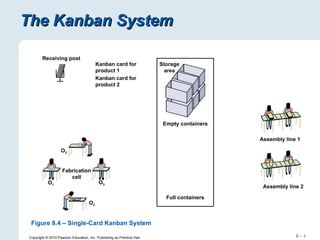

The document describes a single-card Kanban system with a figure showing the flow of materials through different stages of production including receiving, fabrication, storage, and assembly lines. Kanban cards are used to signal the need to replenish materials and allow containers to move between stages only when authorized by a card. The key aspects of Kanban systems are also summarized such as only moving full containers with a card and not exceeding authorized production levels.