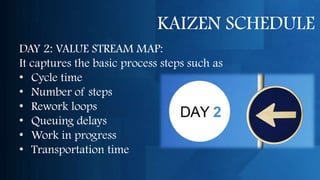

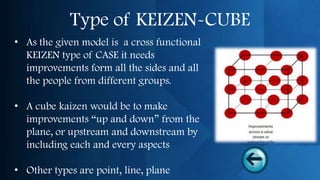

The document discusses Kaizen and its implementation at a national bank through a 5-day Kaizen event. It describes the Kaizen schedule and methodology used which involved identifying problems, creating value stream maps, brainstorming solutions, testing solutions, and presenting findings. Results of the event included reducing cycle times by 30-95%, reducing an administrative process time from 20 to 12 minutes, and reducing complaint resolution time from 30 to 8 days. The Kaizen event was considered a powerful improvement tool as it allowed focused problem solving and creativity to generate immediate productivity and quality gains.