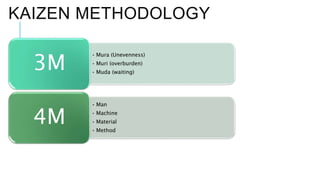

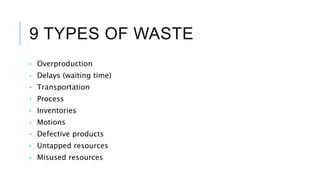

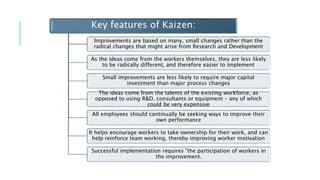

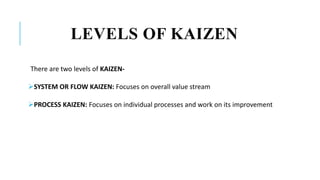

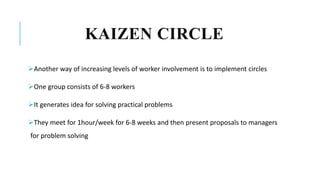

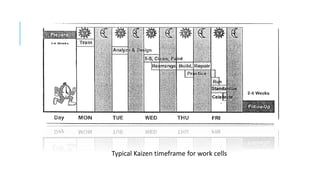

This document provides an overview of Lean Manufacturing and Kaizen. It defines Kaizen as a Japanese term meaning "continuous improvement" and a philosophy that advocates continuously improving products, processes and activities to meet changing customer requirements through the elimination of waste. The document then discusses key aspects of the Kaizen methodology including the 3Ms/4Ms, PDCA cycle, types of waste, and two levels of Kaizen - system/flow and process. It also covers Kaizen principles, steps, mini-Kaizen, Kaizen blitz/events, and provides three case studies on implementing Kaizen approaches.