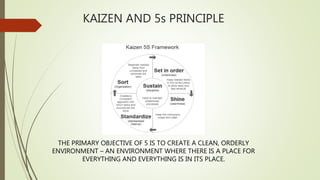

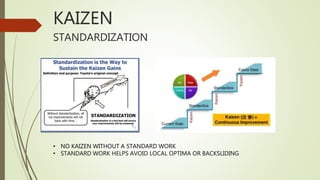

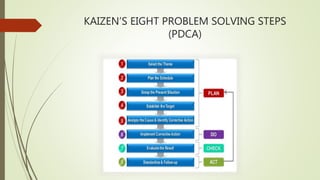

The document discusses the concept of Kaizen, a Japanese philosophy of continuous improvement. It defines Kaizen as an ongoing improvement process involving everyone in an organization. The presentation covers the origins and key benefits of Kaizen, as well as its three pillars: culture, standardization, and visual management. Kaizen aims to eliminate waste from processes through techniques like 5S and identifying the eight deadly wastes. Toyota is highlighted as an example of a company that successfully uses Kaizen principles in its production system. Potential disadvantages of Kaizen like resistance to change are also addressed.