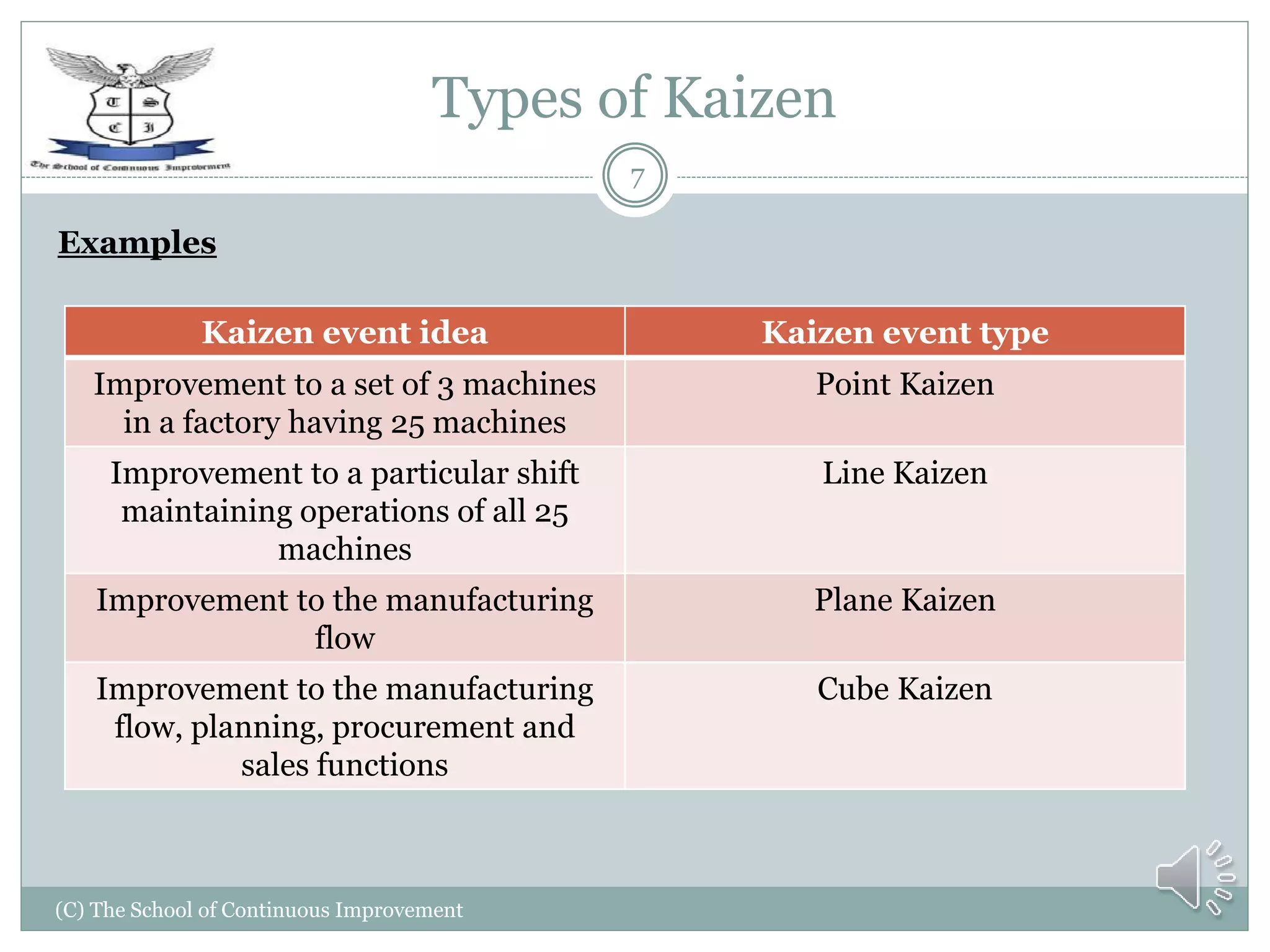

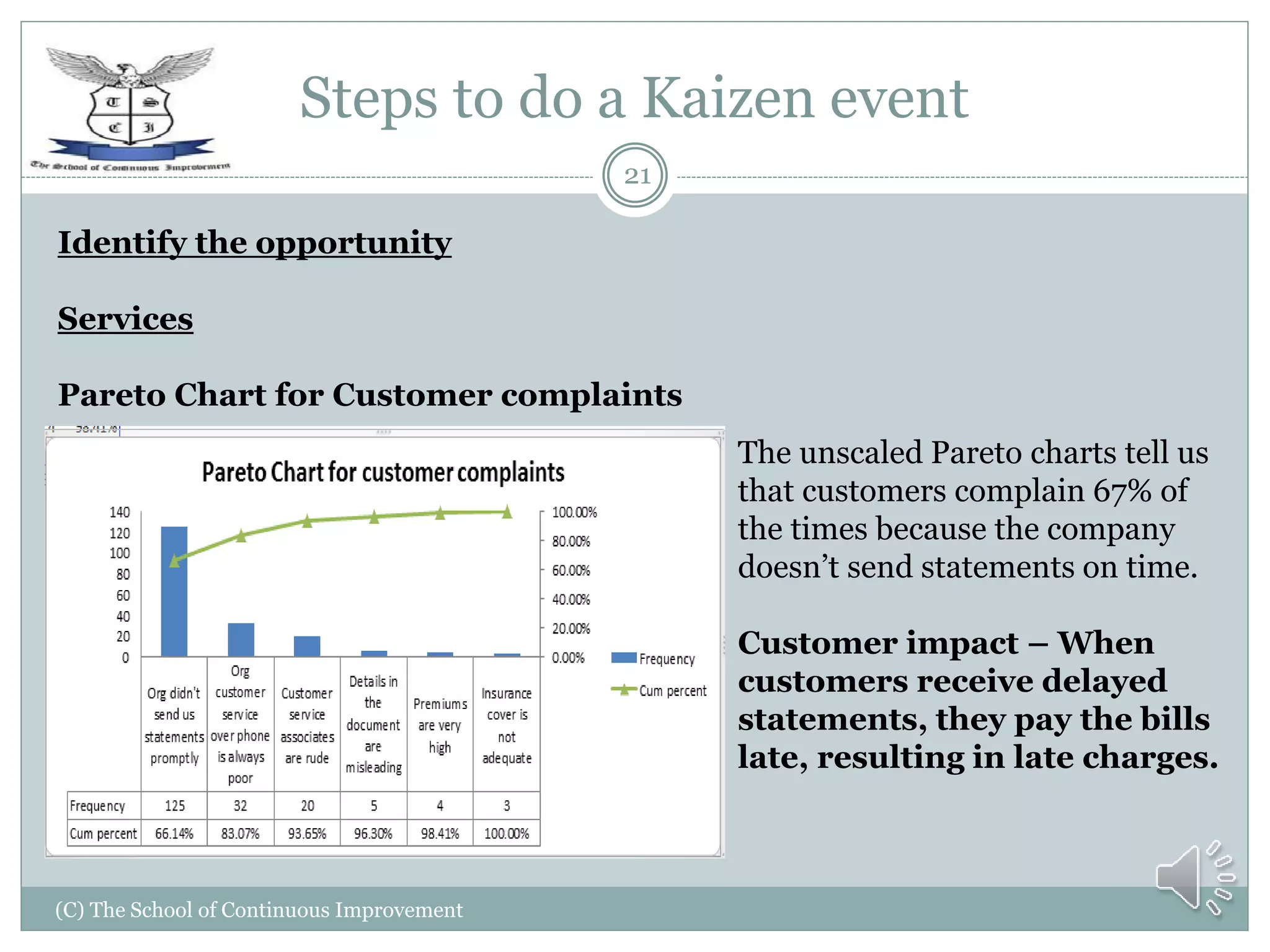

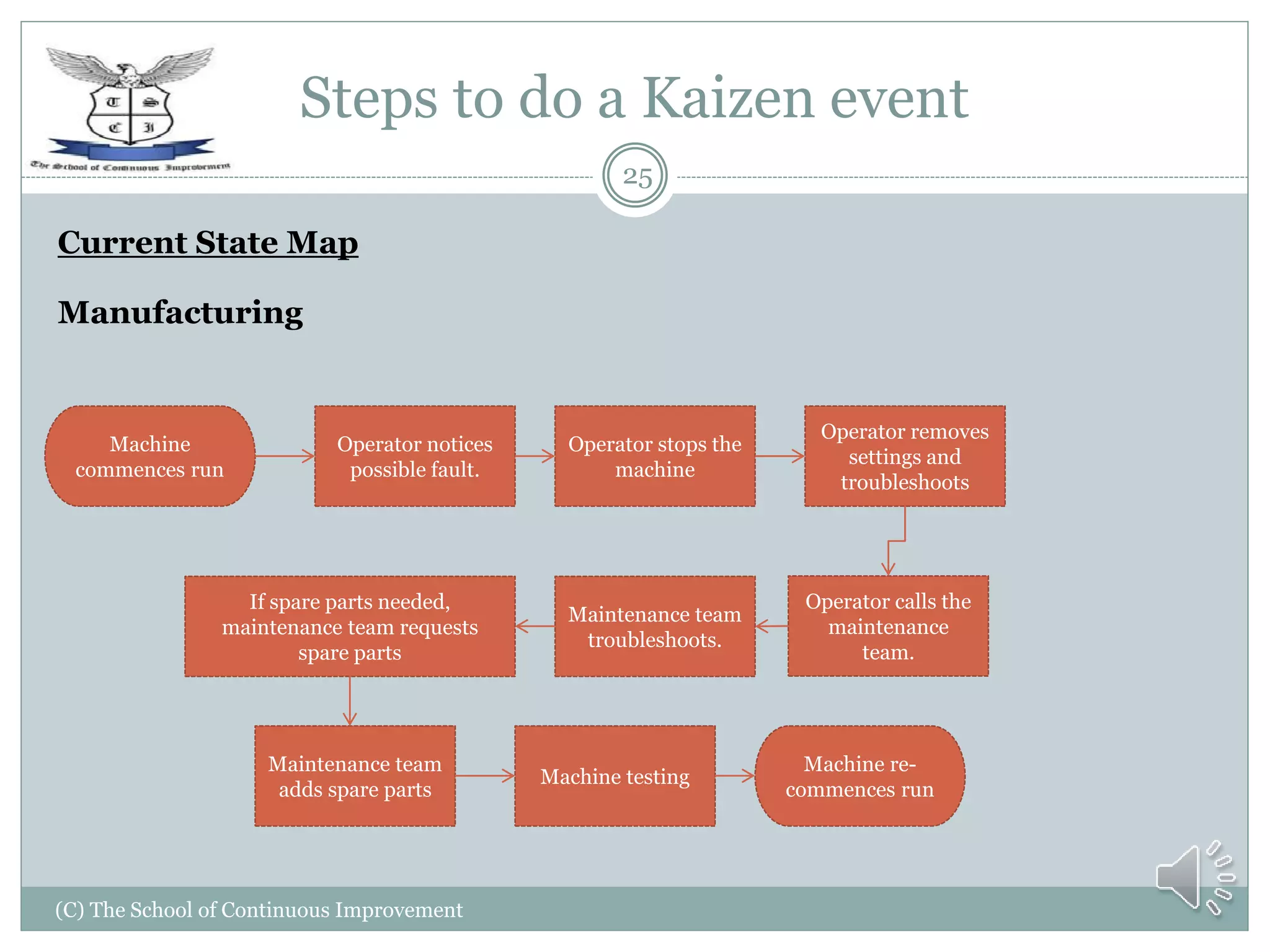

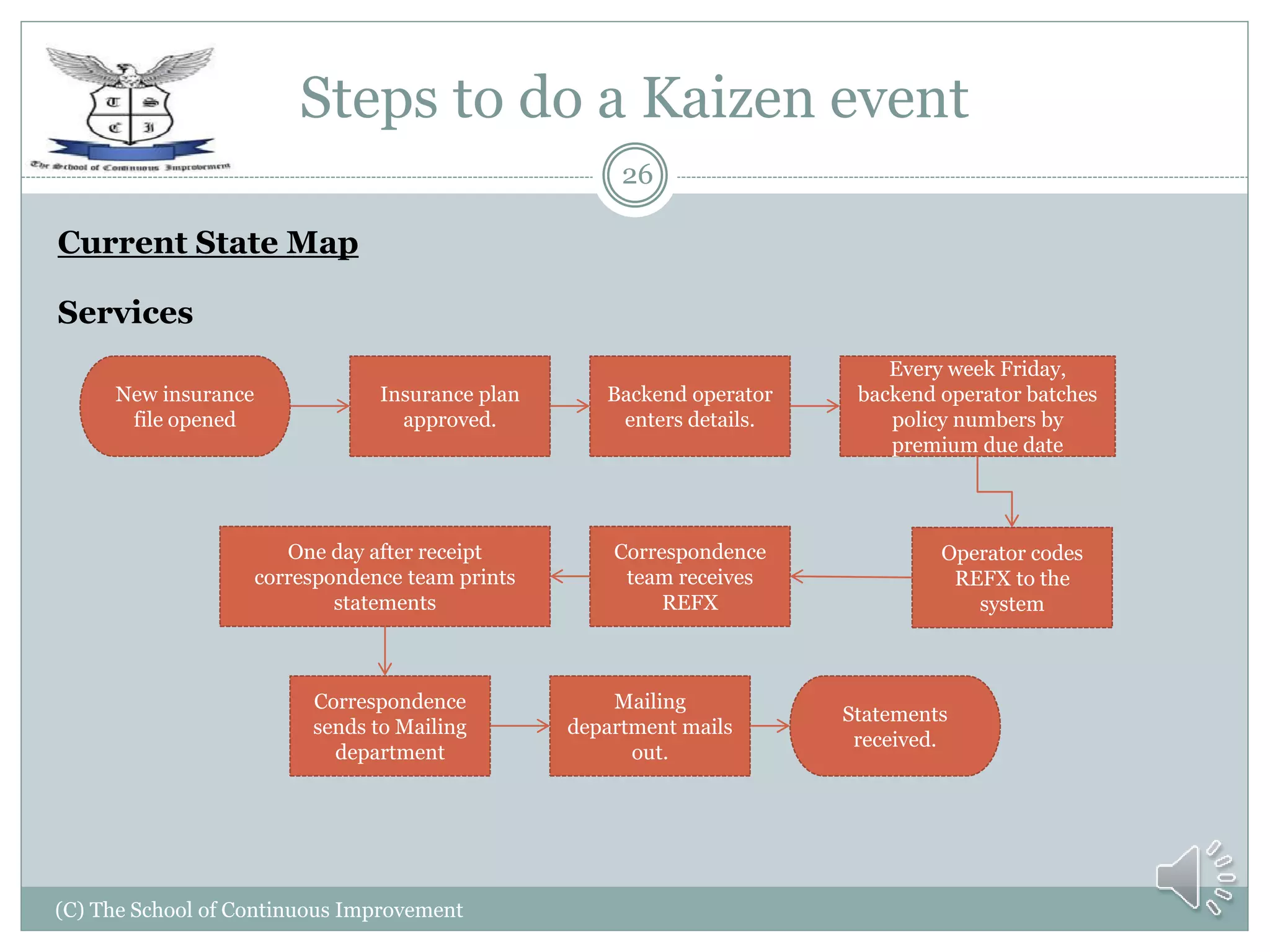

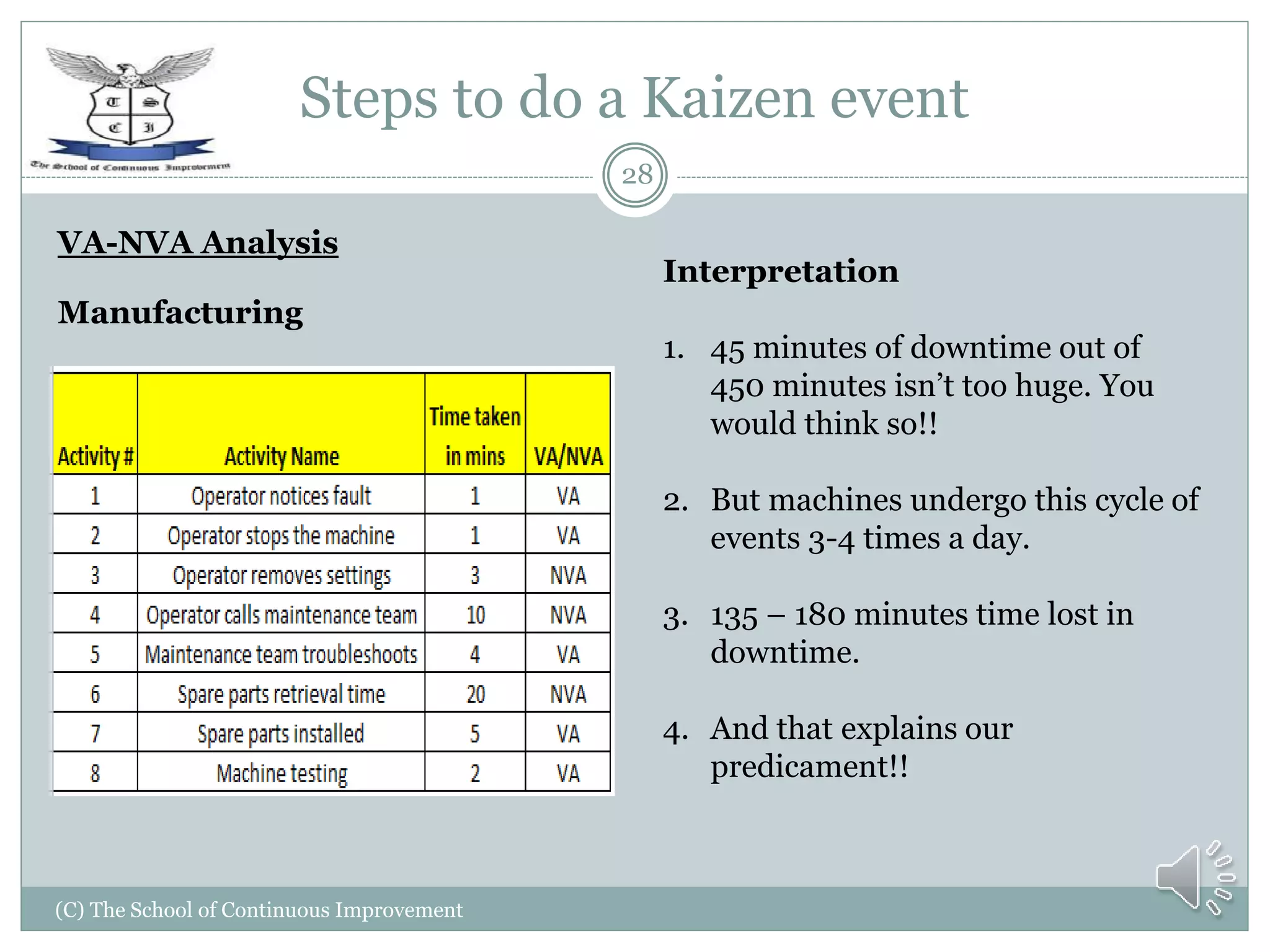

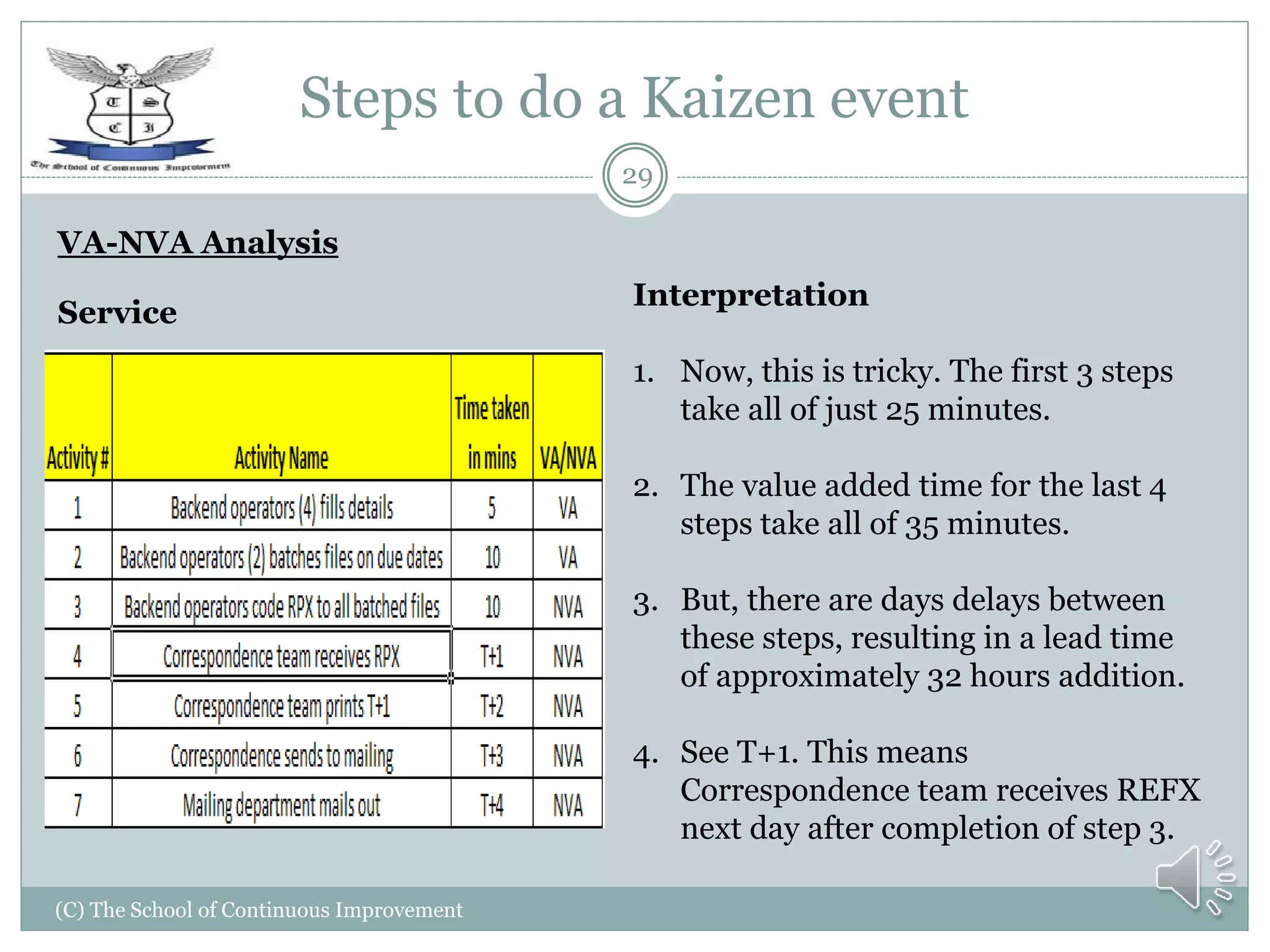

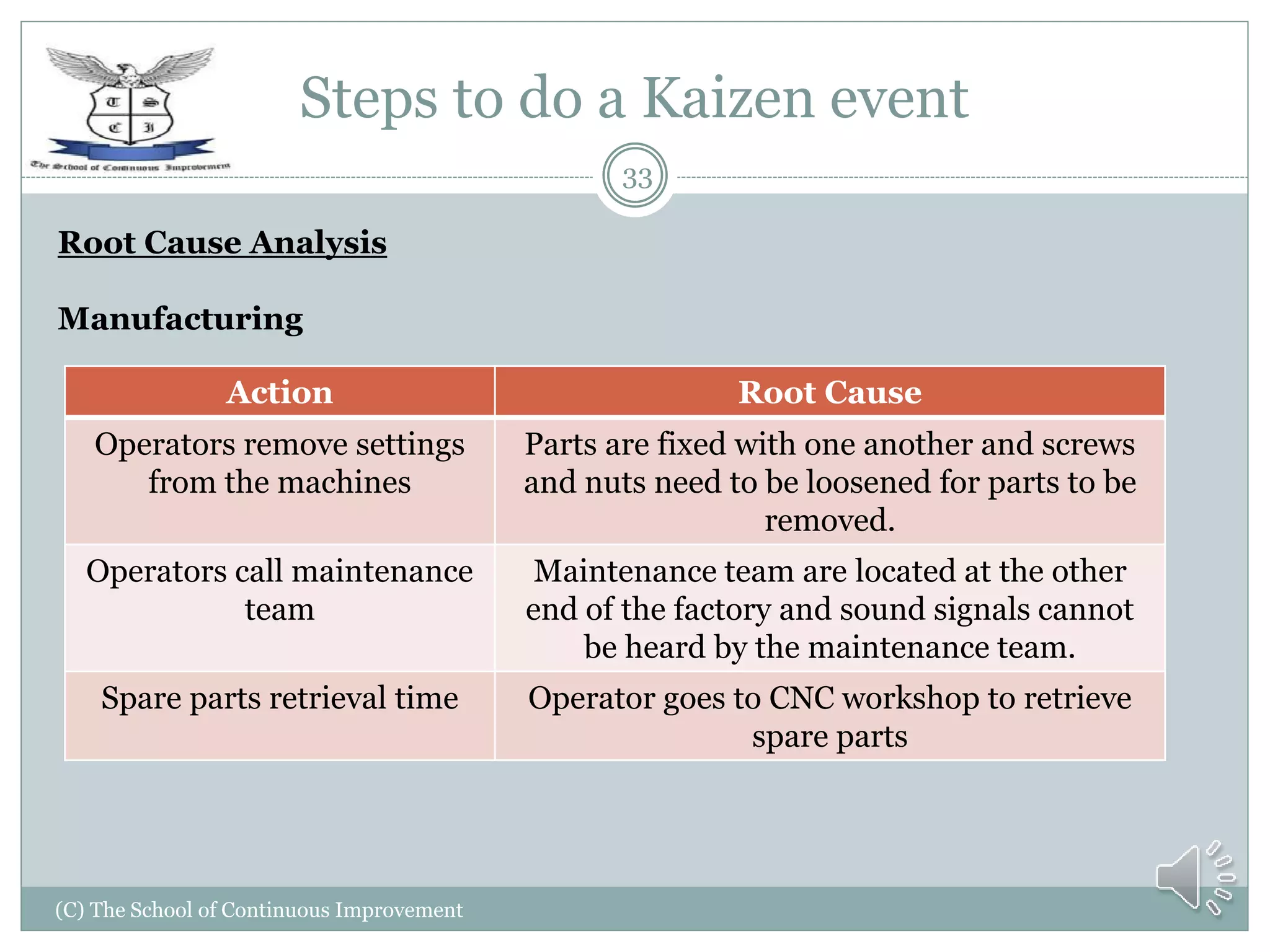

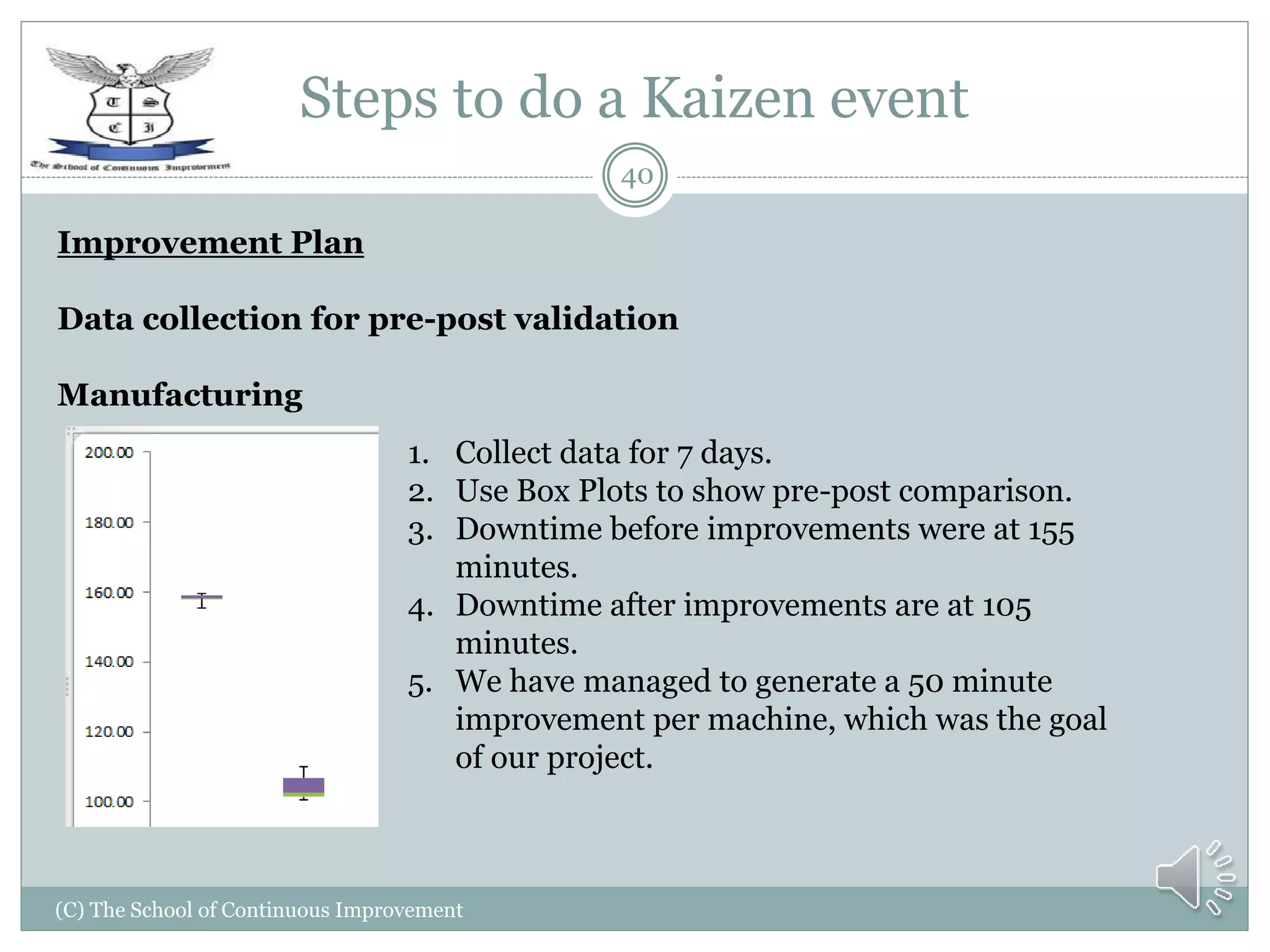

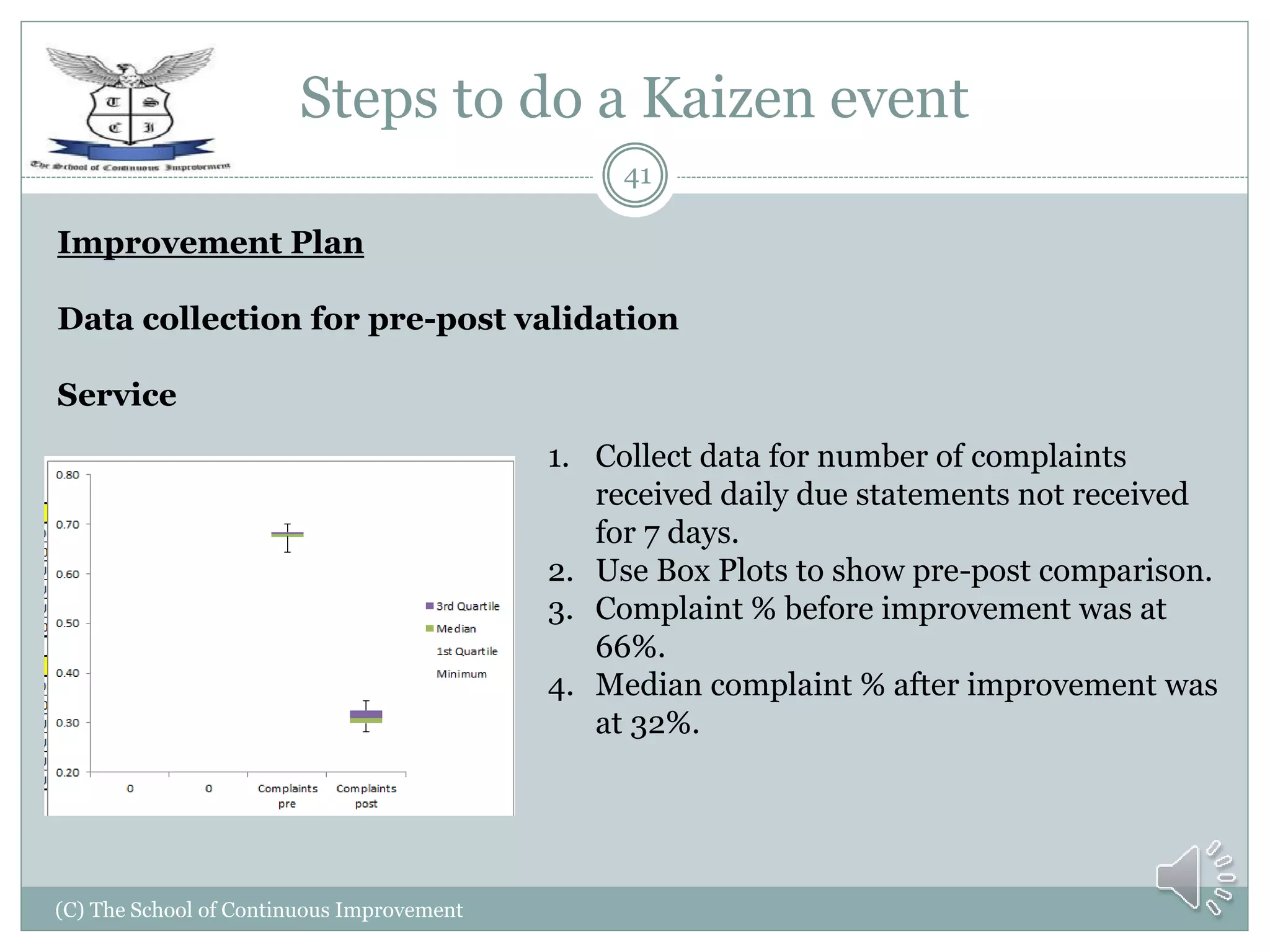

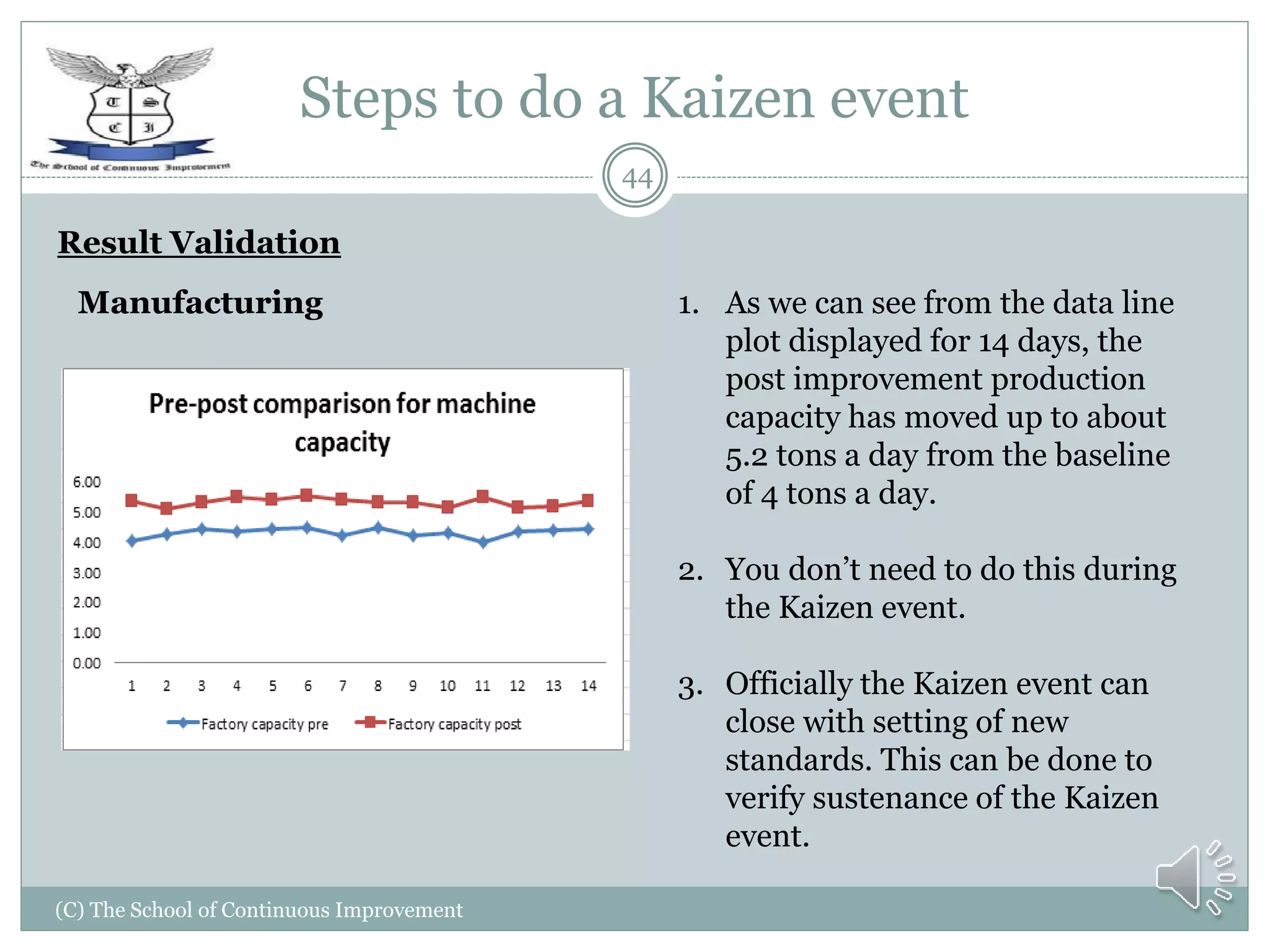

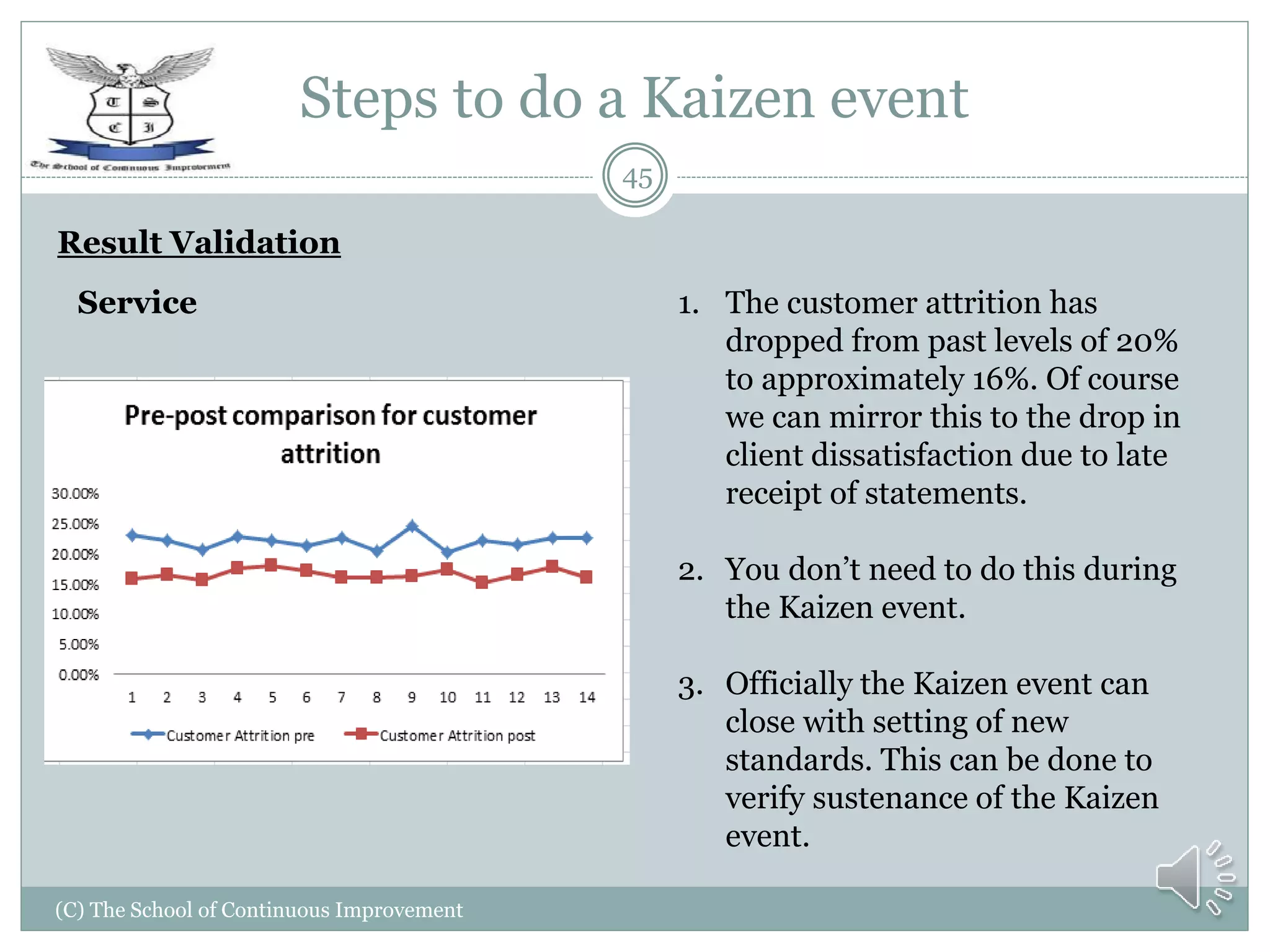

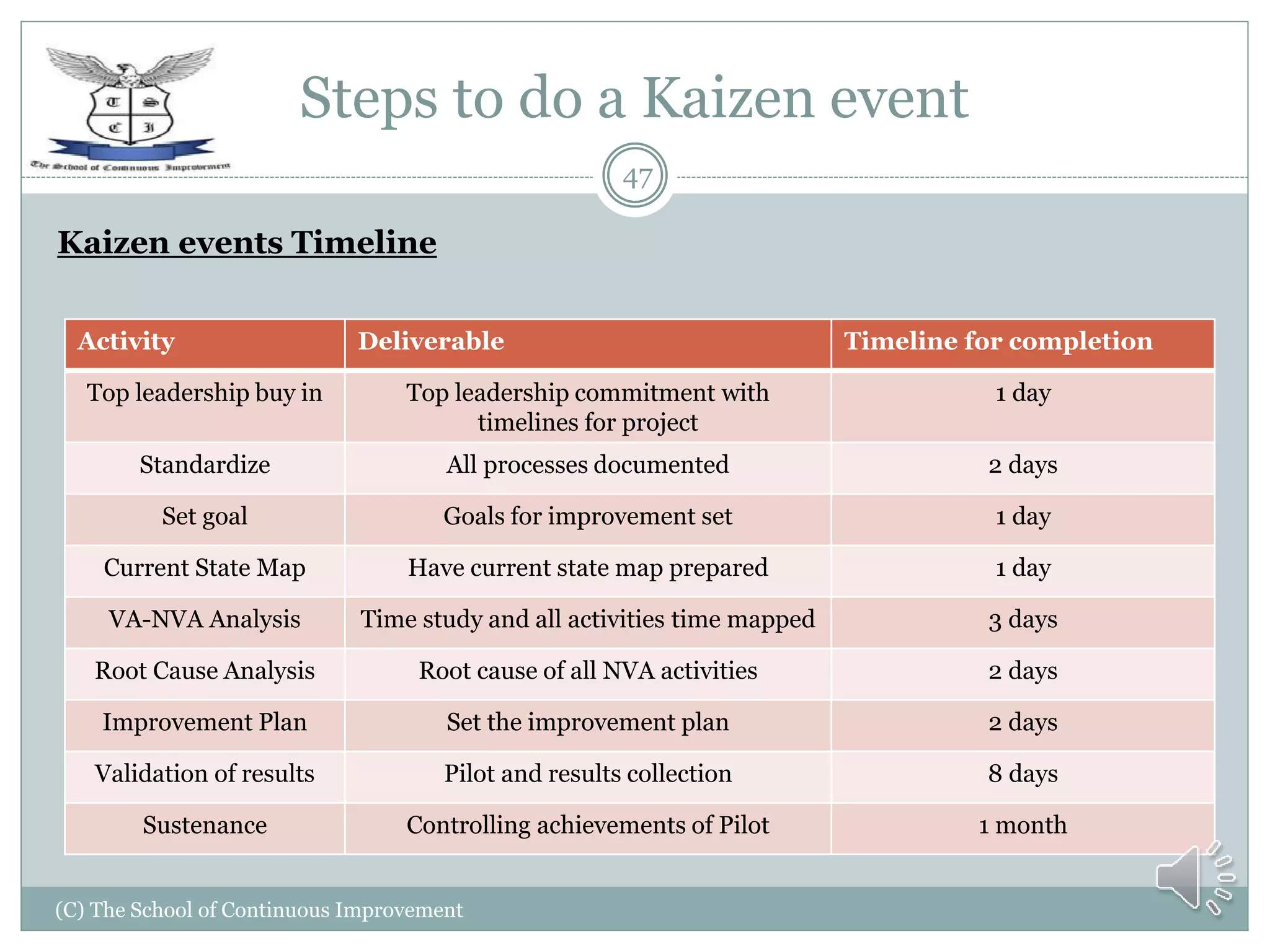

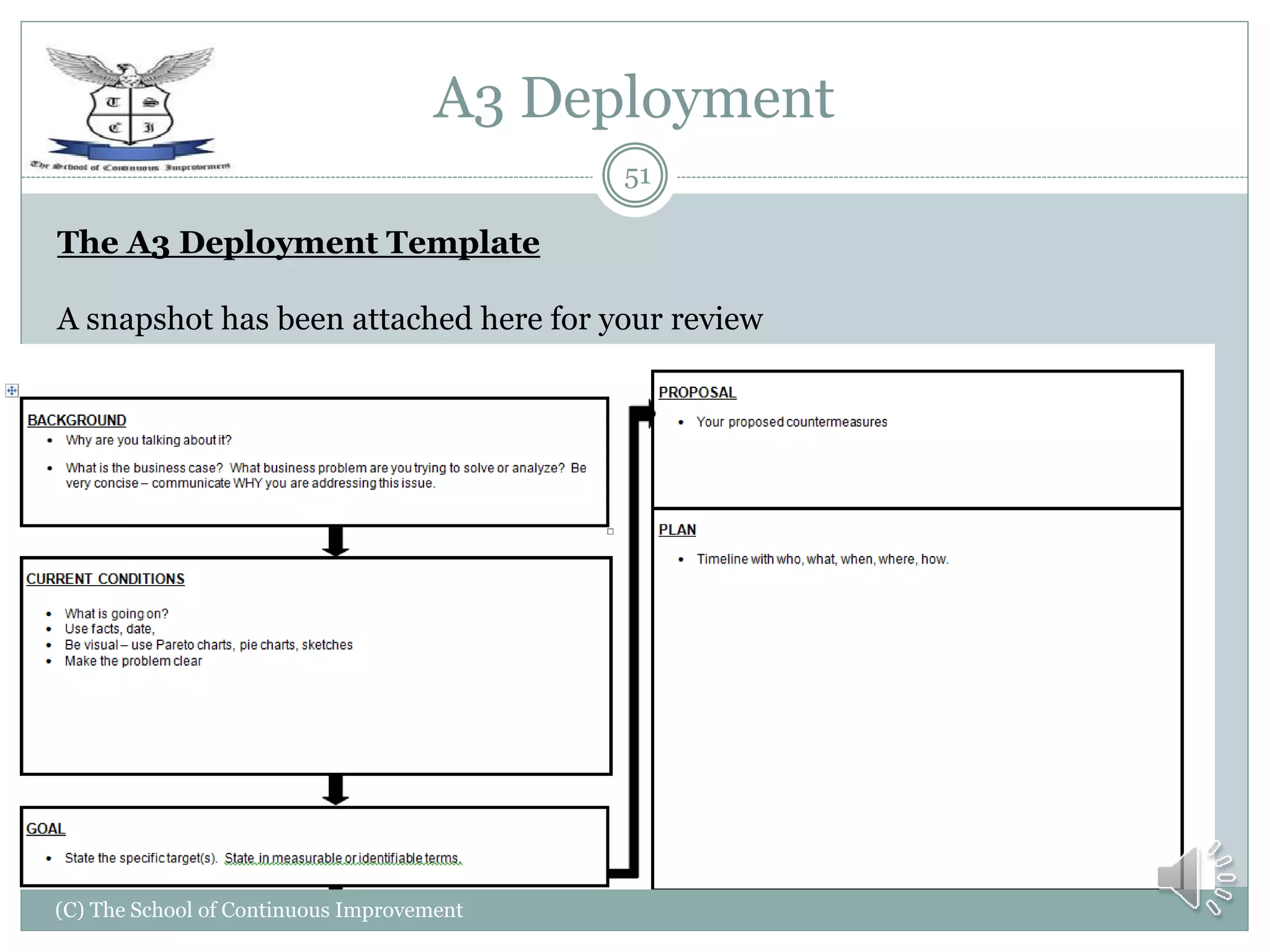

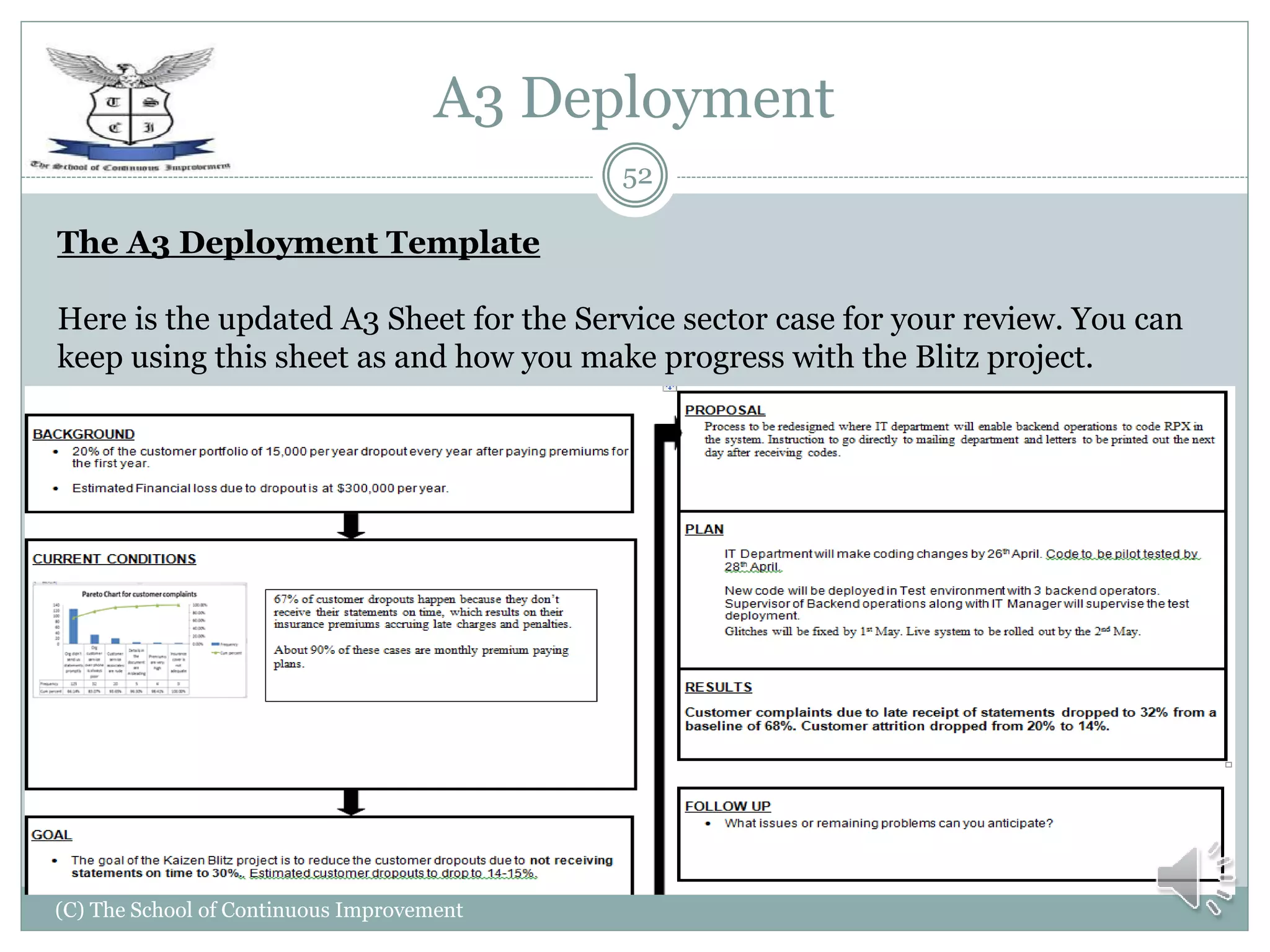

The document outlines a certification program for becoming a Kaizen practitioner, emphasizing the application of the Kaizen philosophy to improve processes, equipment, and people within organizations. It details various forms of Kaizen, such as point, line, plane, and cube, along with the steps necessary to conduct a Kaizen event, including standardization, opportunity identification, goal setting, and root cause analysis. The program highlights the importance of management support and operator involvement while providing tools and methodologies for continuous improvement.