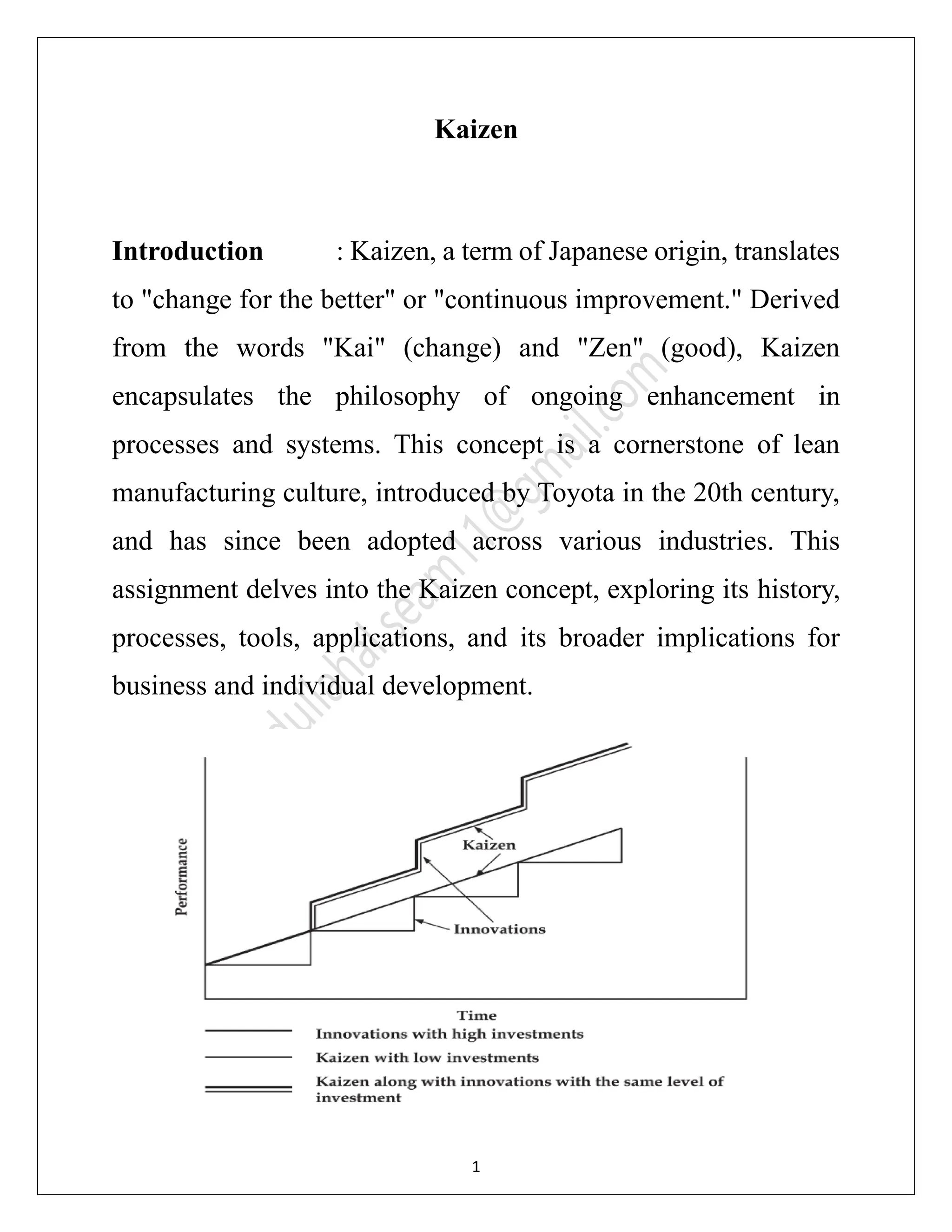

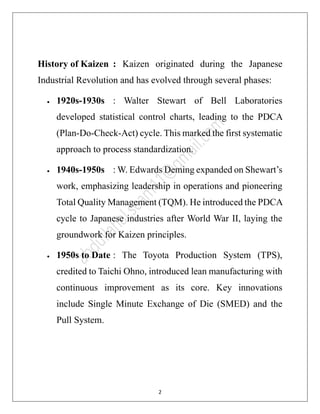

Kaizen, a Japanese term meaning 'continuous improvement,' originates from early 20th-century industrial practices and has become a core principle in lean manufacturing, particularly within Toyota's production system. This philosophy emphasizes employee empowerment to eliminate waste and foster efficiency through tools like the PDCA cycle, fishbone diagrams, and value stream mapping. Kaizen's broader implications extend beyond industries to personal development, advocating for incremental improvements in various aspects of life.