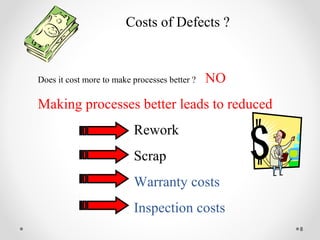

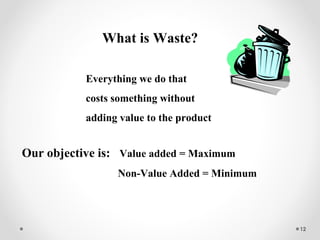

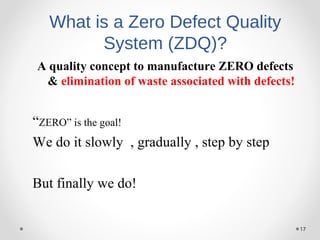

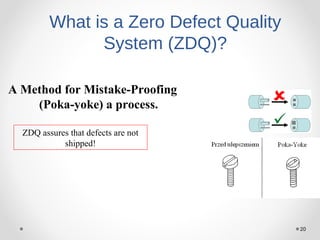

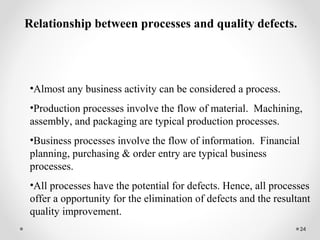

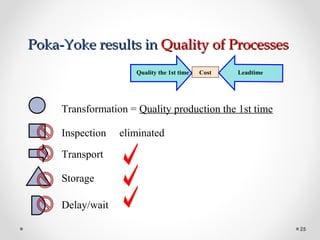

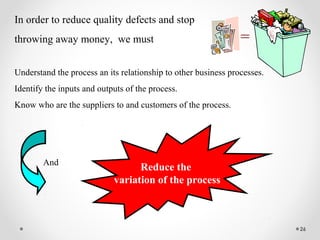

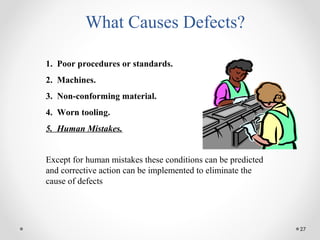

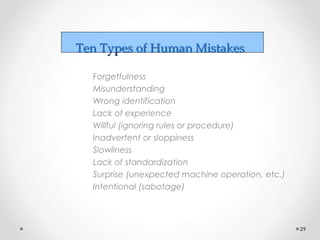

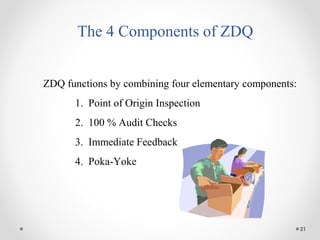

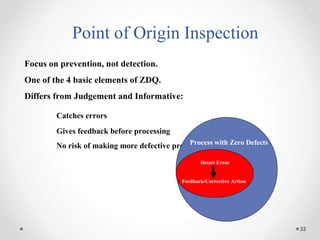

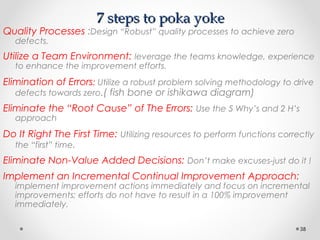

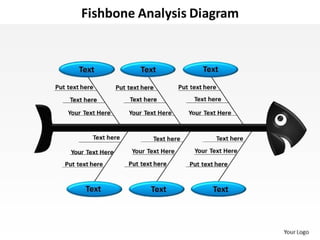

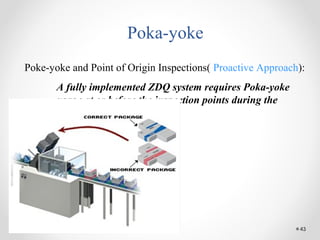

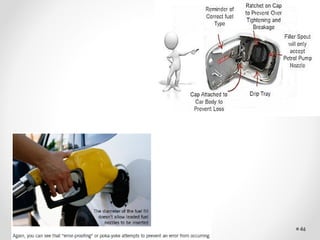

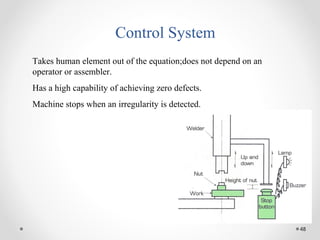

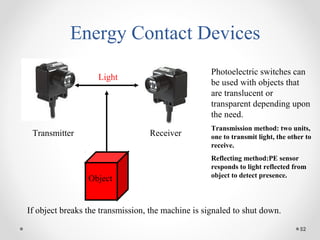

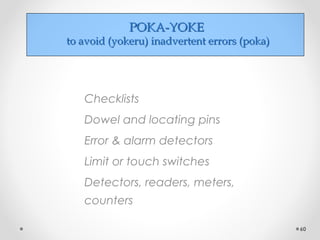

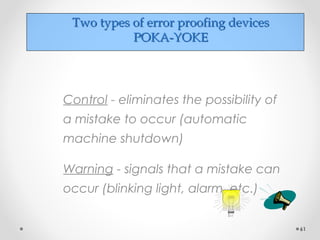

The document discusses the concept of zero defects quality (ZDQ) and poka-yoke, which is a Japanese term that means "mistake-proofing". ZDQ aims to manufacture products with zero defects by focusing on preventing errors rather than detecting errors through inspection. This is achieved through four key elements: point of origin inspection, 100% audit checks, immediate feedback on errors, and poka-yoke methods to make processes mistake-proof. Poka-yoke involves designing processes so that human errors are either prevented or detected immediately. The document outlines seven steps to achieve poka-yoke, including designing robust processes and eliminating the root causes of errors.