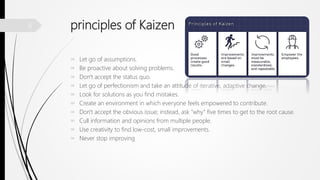

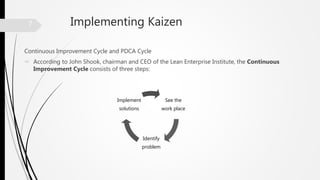

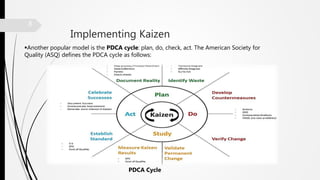

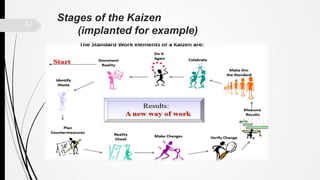

Kaizen is a Japanese philosophy of continuous improvement involving all employees. It was influenced by American teachings and adopted by Toyota to continuously improve processes through small, ongoing changes rather than radical changes. Key elements include quality, effort, employee involvement, and willingness to change. Popular Kaizen tools and principles are used to implement ongoing improvements through the continuous improvement cycle and PDCA (plan-do-check-act) model. Benefits include increased productivity, efficiency, quality and profits while minimizing waste. Successful real-life examples include Toyota, Lockheed Martin, Ford Motor Company, and Pixar Animation Studios.