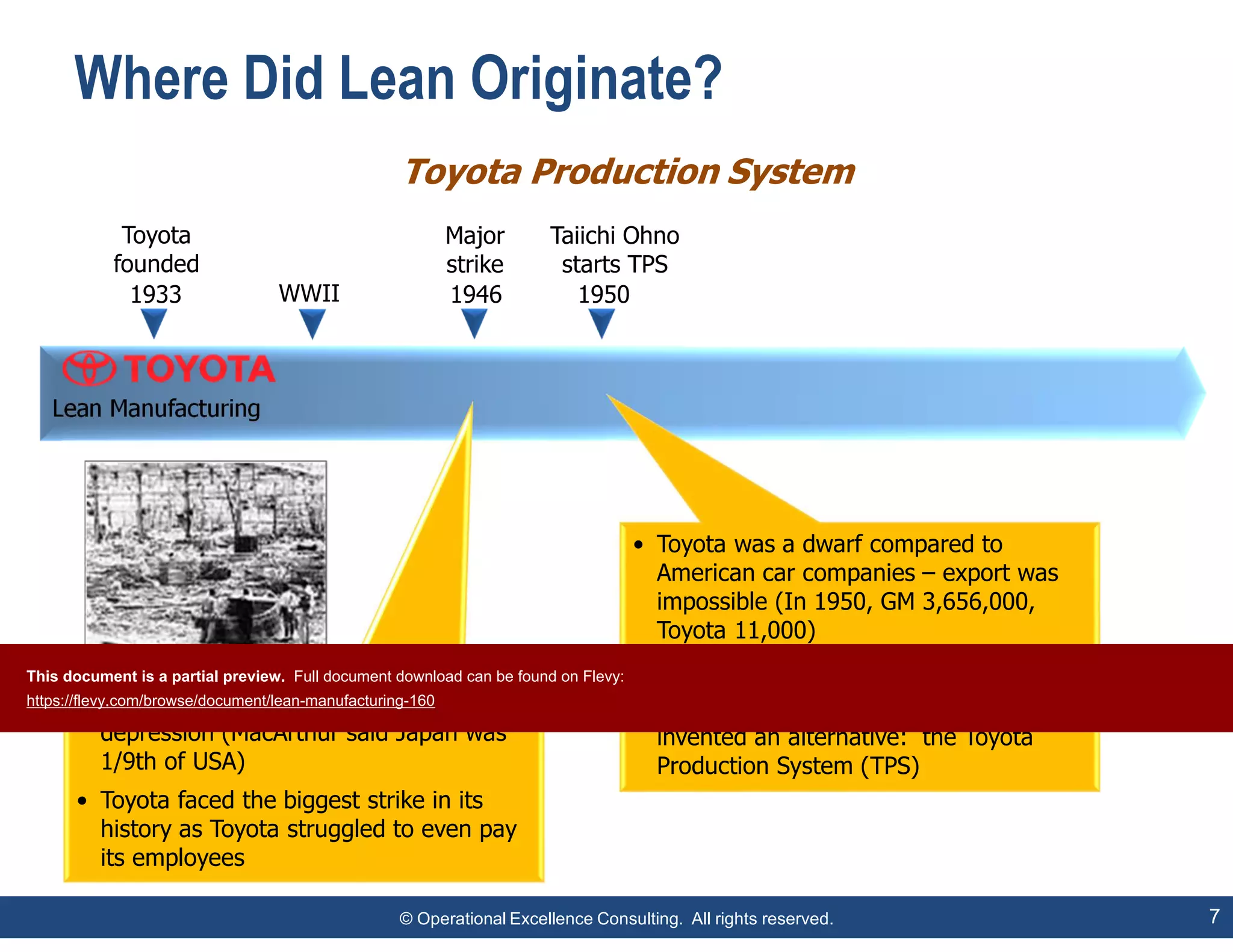

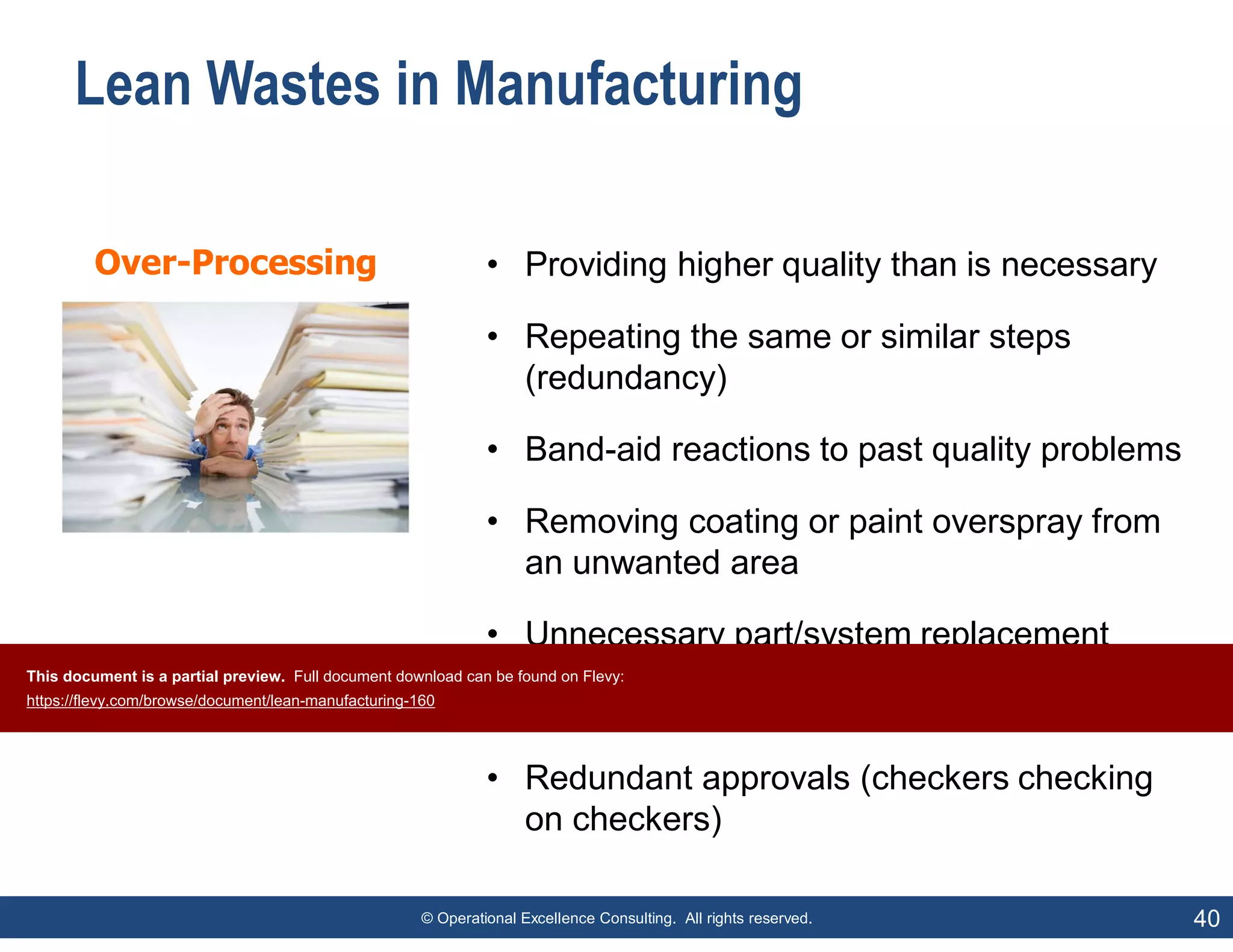

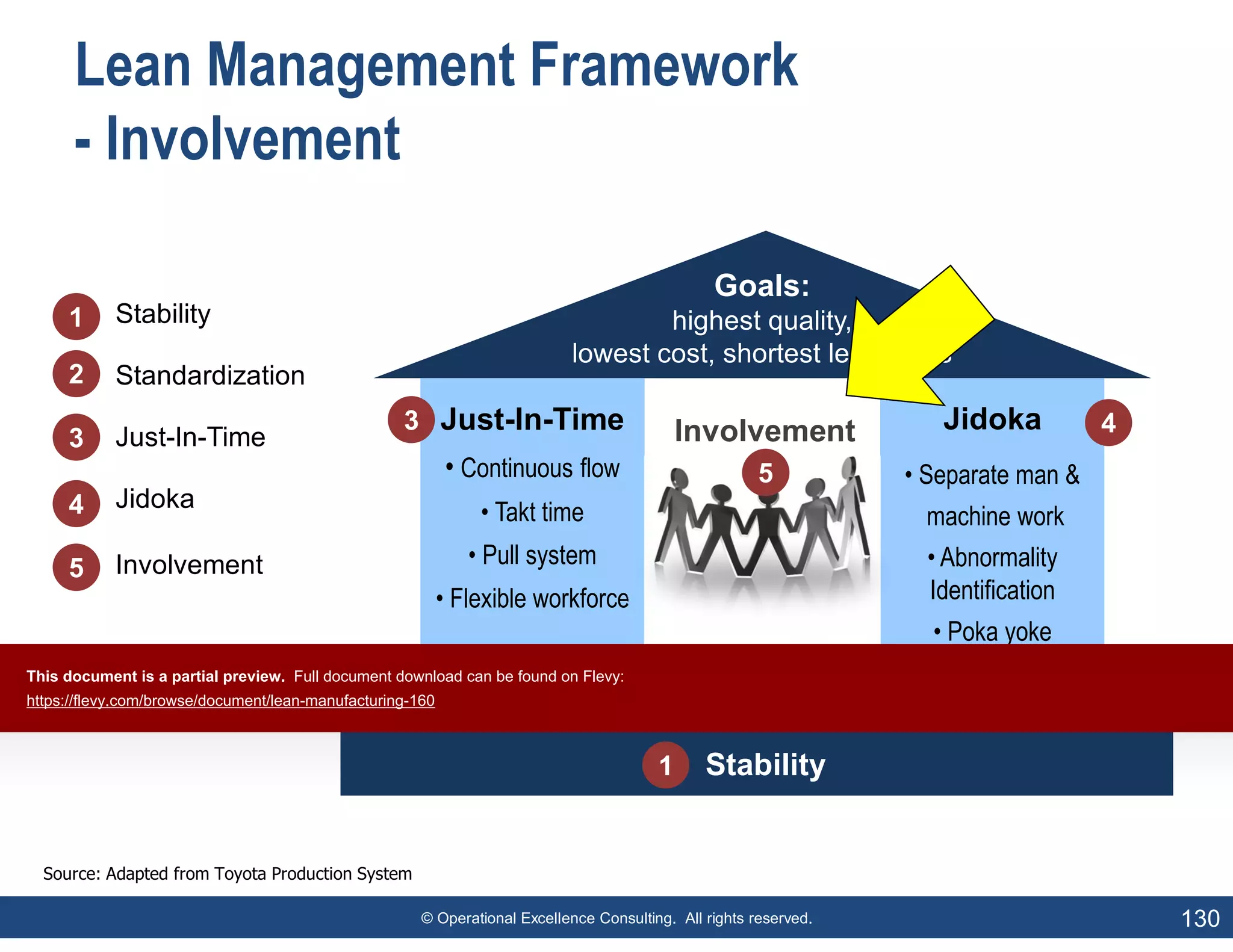

The document provides an overview of lean manufacturing, emphasizing its origins at Toyota and its evolution across various industries. It discusses key principles such as waste elimination, just-in-time production, and the importance of continuous improvement through methods like kaizen. Additionally, it outlines the transition from traditional to lean thinking and highlights the core concepts of the Toyota Production System, including jidoka and a pull-based system.