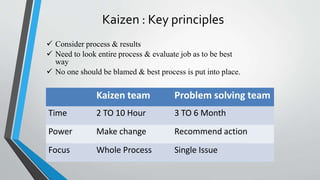

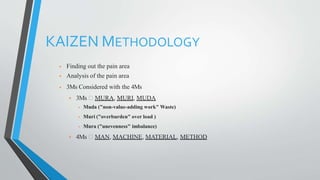

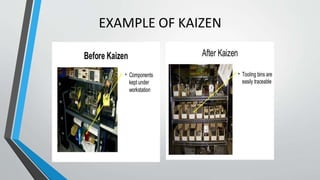

Kaizen is a Japanese philosophy that focuses on continuous improvement involving everyone. It aims to make small, gradual improvements over time with minimal costs. Some key aspects of Kaizen include identifying waste (muda), overburden (muri), and unevenness (mura) and using tools like 5S, PDCA cycles, quality circles, and kanban. Toyota successfully implemented Kaizen to improve efficiency and working conditions. Applying Kaizen principles can lead to benefits like reduced waste, improved quality and productivity, and increased employee satisfaction.