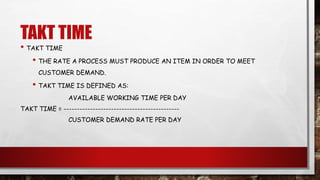

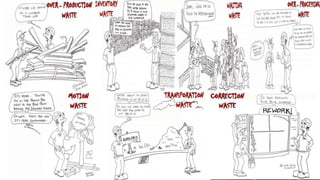

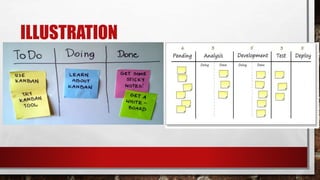

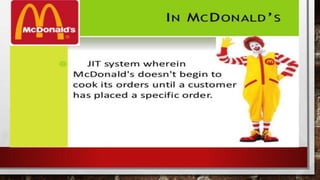

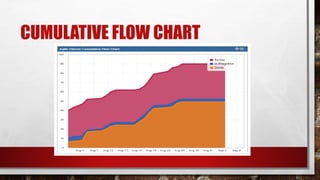

The document discusses Just-in-Time (JIT) manufacturing. It defines JIT as eliminating waste and continuously improving productivity. Key aspects of JIT include minimizing stock levels, goods only being produced to meet customer orders, and a close manufacturer-supplier relationship. JIT aims to maximize output at lowest unit cost through continuous flow processing and adherence to takt times. The founder of JIT was Taiichi Ohno at Toyota in the 1950s. Benefits of JIT include reduced costs and increased cash flow. Kanban is a scheduling system used with JIT to visually manage workflow and limit work-in-progress.