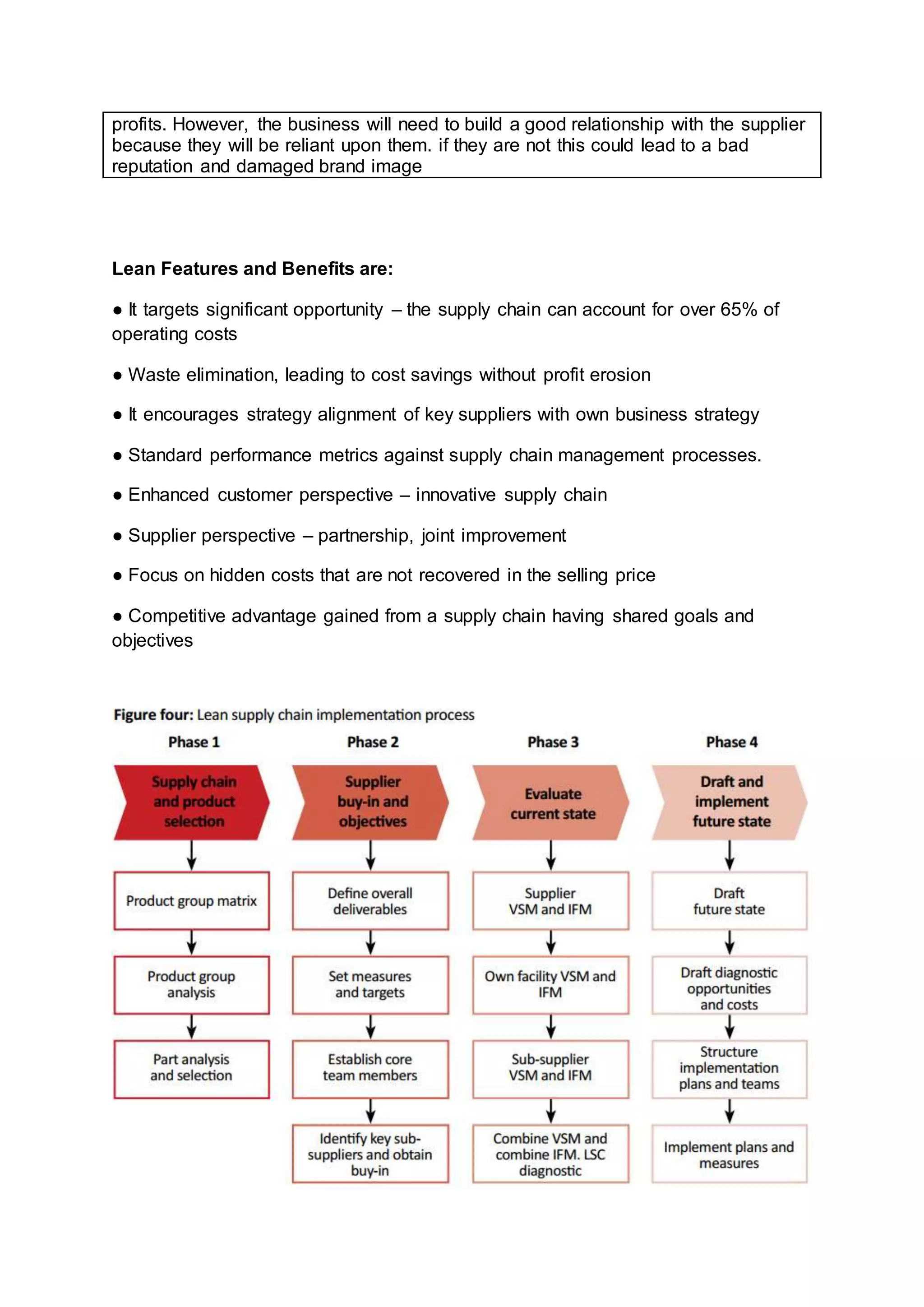

The document discusses Lean, which aims to maximize customer value while minimizing waste. Key aspects of Lean covered include:

- The five principles of Lean manufacturing: defining value, mapping the value stream, creating flow, using a pull system, and pursuing perfection.

- The seven wastes in manufacturing: transportation, inventory, motion, waiting, over-processing, overproduction, and defects.

- Value stream mapping provides a visual representation of material and information flow, helping to identify waste. A future state map represents the ideal flow.

![Coca Cola Example

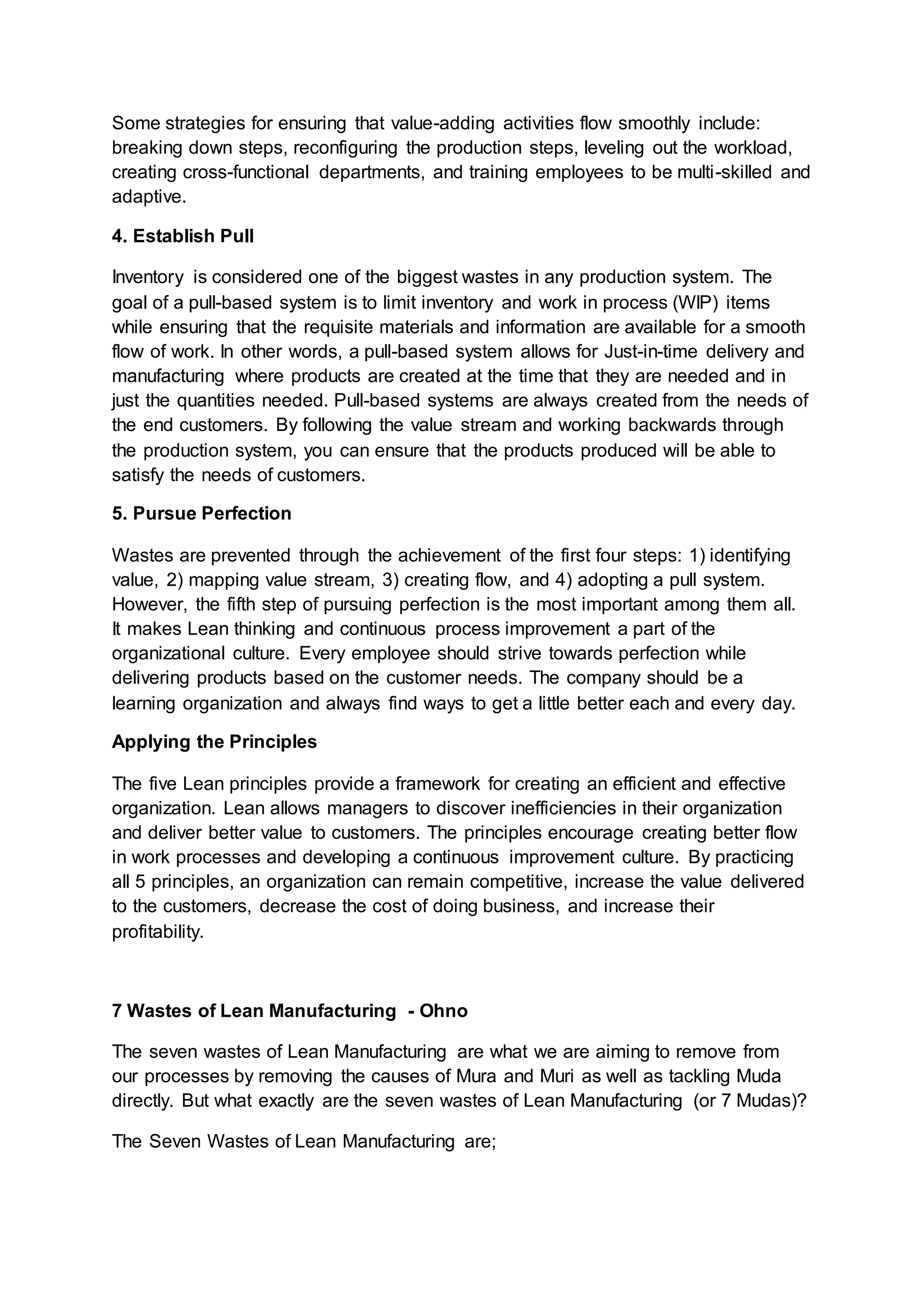

Did you know that it takes 319 days to produce Coca Cola from the point that it is

bauxite to the point that is ready for sales in your average Tesco store[2]?

The amount of time when value is actually being created (3 hours) is infinitesimal in

relation to the total time (319 days) from bauxite to recycling bin. More than 99

percent of the time the value stream is not flowing at all: the Muda of waiting.

Second, the can and the aluminium going into it are picked up and put down thirty

times. From the customer's standpoint none of this adds any value: the Muda of

transport. Similarly, the aluminium and cans are moved through fourteen storage lots

and warehouses, many of them vast, and the cans are palletized and unpalletized

four times: the Muda of inventories and excess processing. Finally, fully 24 percent

of the energy-intensive, expensive aluminium coming out of the smelter never makes

it to the customer: the Muda of defects (causing scrap).

Velocity ratio Coca Cola=Value added time/total processing

time=3h/7656h=0,00039%

Lean production

Advantages Disadvantages

•Lead times are cut

•Damage, waste and loss of

stocks/equipment are lowered

•A greater focus on customer needs

•Improved quality through the

introduction of kaizen and quality

circles

•Lower costs and contribute to

improved profits

•Staff are more involved and

potentially more motivated

•Working environments are safer and

cleaner

•Reduced floor space

•Improved flexibility to react to

changes

Efficiency-By defining processes,

developing management and

implementing strategies such as the

5 S’s (Sort, Streamline, Shine,

Standardise and Sustain), companies

can therefore improve productivity.

•The business may struggle to meet orders if

their suppliers fail to deliver raw materials on

time or of the right quality!!

•The business is unlikely to 'bulk buy' its raw

materials and, therefore, it may lose the

benefit of achieving economies of scale

•Buffer stocks are minimal and this may lead

to the business having to reject customer

orders requiring delivery immediately

•Commitment- For Lean to be successful,

commitment and focus are need by all

involved. Team unity and sometimes

additionally training are required.

Time-Adopting anything into a company can

be tricky but more significantly, it can be time

consuming. Instant results are not

guaranteed as it takes time to implement

new techniques.

Lean production reduces waste and the costs involved in stock, therefore improving](https://image.slidesharecdn.com/leannotes-200418160804/75/Lean-notes-7-2048.jpg)