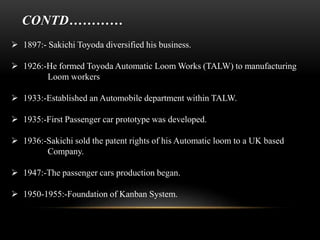

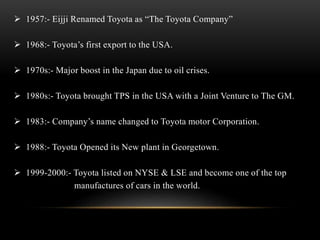

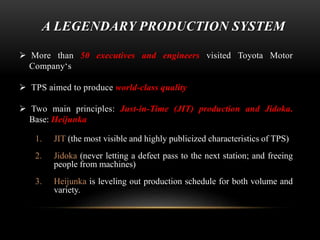

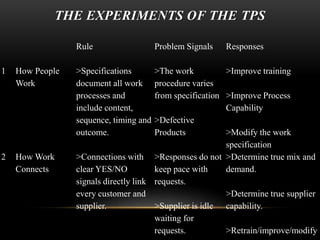

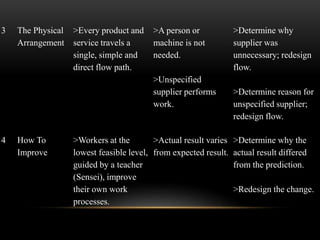

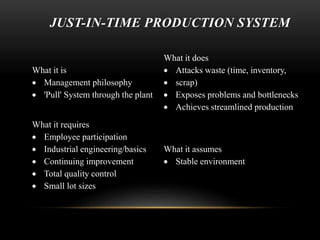

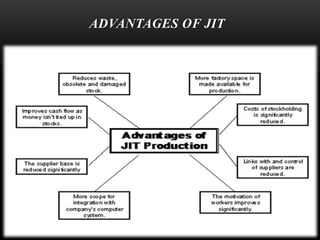

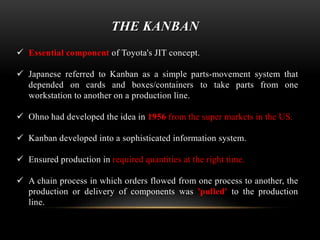

Toyota developed the Toyota Production System (TPS), which includes just-in-time (JIT) production and other lean manufacturing principles. TPS aims to eliminate waste and optimize efficiency through practices like producing only what is needed when it is needed, thereby reducing inventory costs. JIT was pioneered in Toyota's plants in the 1950s and focuses on continuous improvement, small lot sizes, and stable production schedules. The system transformed Toyota into one of the world's largest and most efficient automakers.