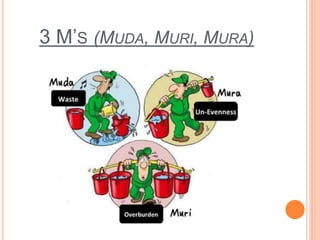

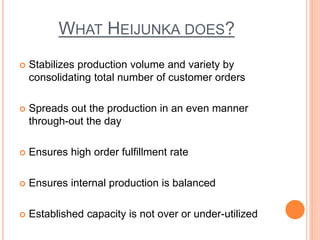

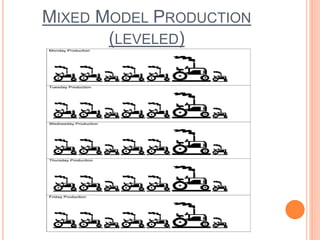

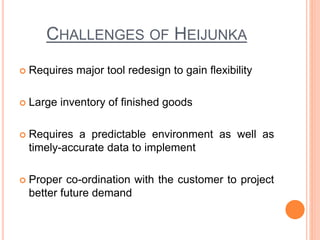

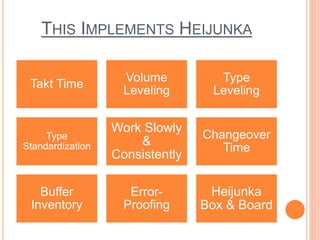

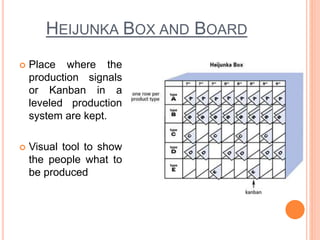

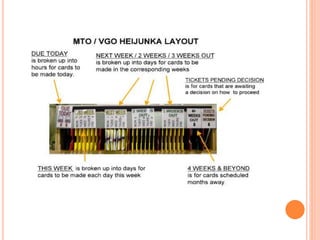

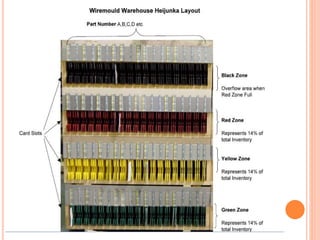

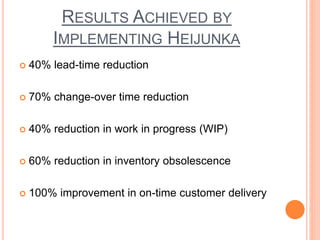

This document discusses the Toyota Production System principle of leveling out workload (Heijunka) to stabilize production volume and variety. Heijunka spreads customer orders evenly throughout production to optimize capacity utilization and ensure high order fulfillment. It balances resource usage and reduces risk of excess inventory compared to an uneven, build-to-order approach. Implementing Heijunka requires changes to production planning and inventory management using tools like takt time, standard work, and a Heijunka box to visualize the leveled schedule.