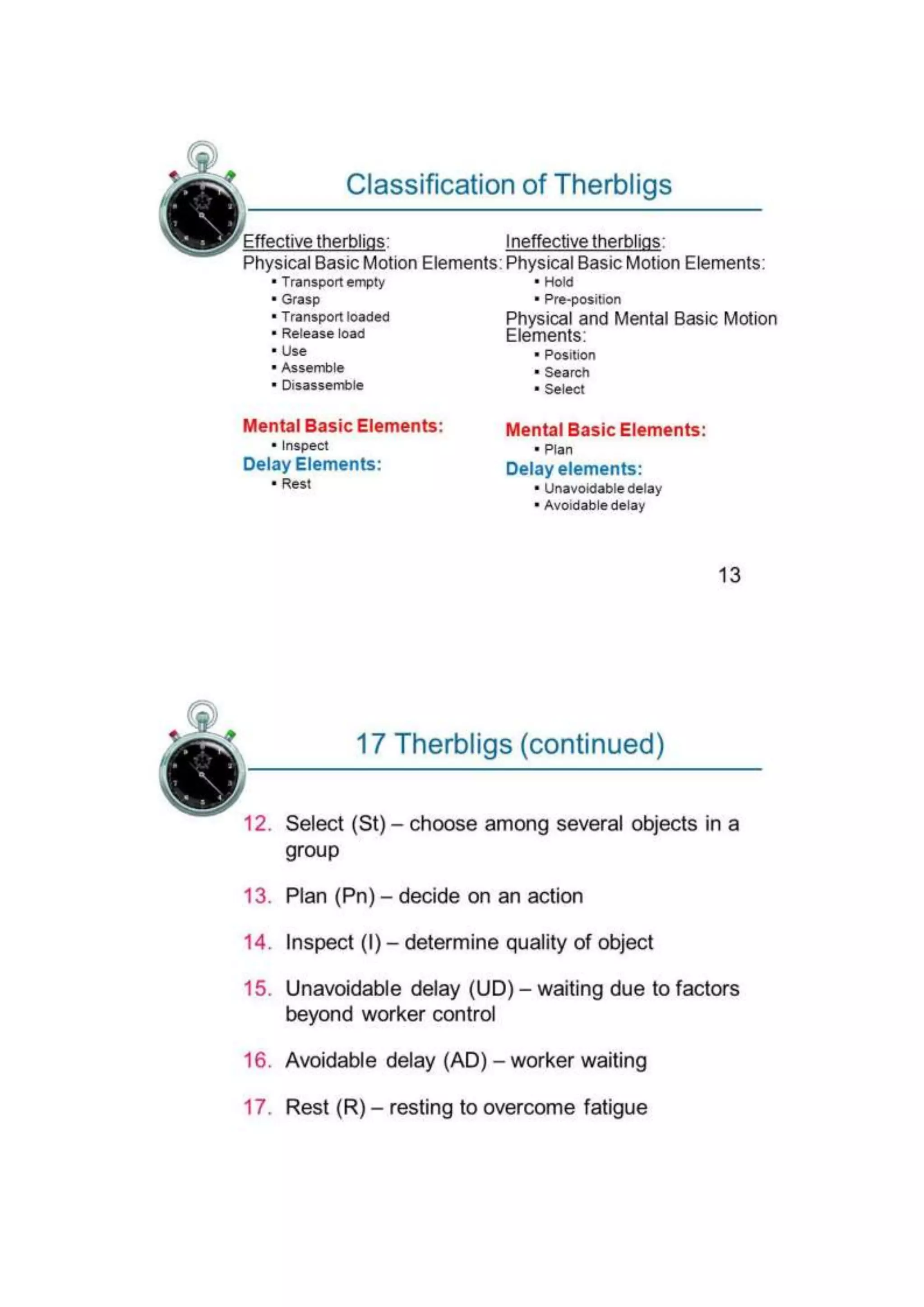

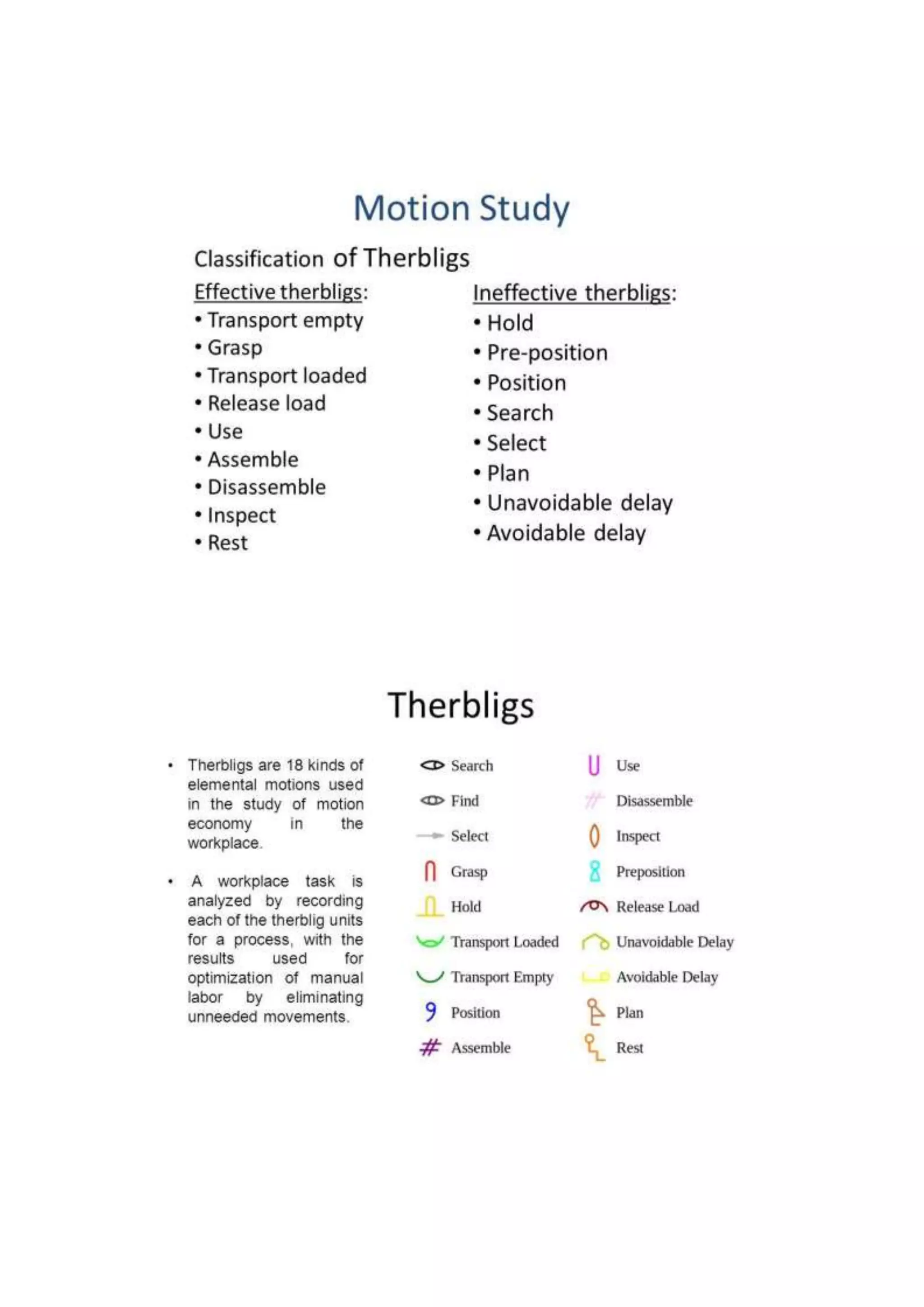

The document discusses the basic motion elements or "therbligs" used in work measurement and analysis. It describes the 18 standardized therbligs which represent fundamental manual motions. These include elements like reach, grasp, transport, hold, release, position, use, assemble, etc.

It then provides an example of how therbligs can be used to analyze the motions in a simple task like shaving. Each motion, such as locating the razor, selecting it, grasping it, and positioning it on the face, is represented by a therblig.

Finally, it introduces the concept of work factor analysis which breaks down manual tasks into standardized motion elements and assigns time values in order to set productivity standards.

![The basic motion elements

The 18 therbligs.

A basic motion element is one of a set of fundamental motions required for a worker

to perform a manual operation or task. The set consists of 18 elements, each

describing a standardized activity.

Transport empty [unloaded] (TE): reaching for an object with an empty hand. (Now

called "Reach")

Grasp (G): grasping an object with the active hand.](https://image.slidesharecdn.com/therbligsdetails-180219193754/75/Therbligs-details-1-2048.jpg)

![on

Inspect

Example usage

Here is an example of how therbligs can be used to analyze motion:[1]

...Suppose a man goes into a bathroom and shave. We'll assume that

his face is all lathered and that he is ready to pick up his razor. He

knows where the razor is, but first he must locate it with his eye. That

is "search", the first Therblig. His eye finds it and comes to rest -- that's

"find", the second Therblig. Third comes "select", the process of

sliding the razor prior to the fourth Therblig, "grasp." Fifth is

"transport loaded," bringing the razor up to his face, and sixth is

"position," getting the razor set on his face. There are eleven other

Therbligs -- the last one is "think"!

— Frank Gilbreth, Jr. and Ernestine Gilbreth Carey, Cheaper By the](https://image.slidesharecdn.com/therbligsdetails-180219193754/75/Therbligs-details-3-2048.jpg)