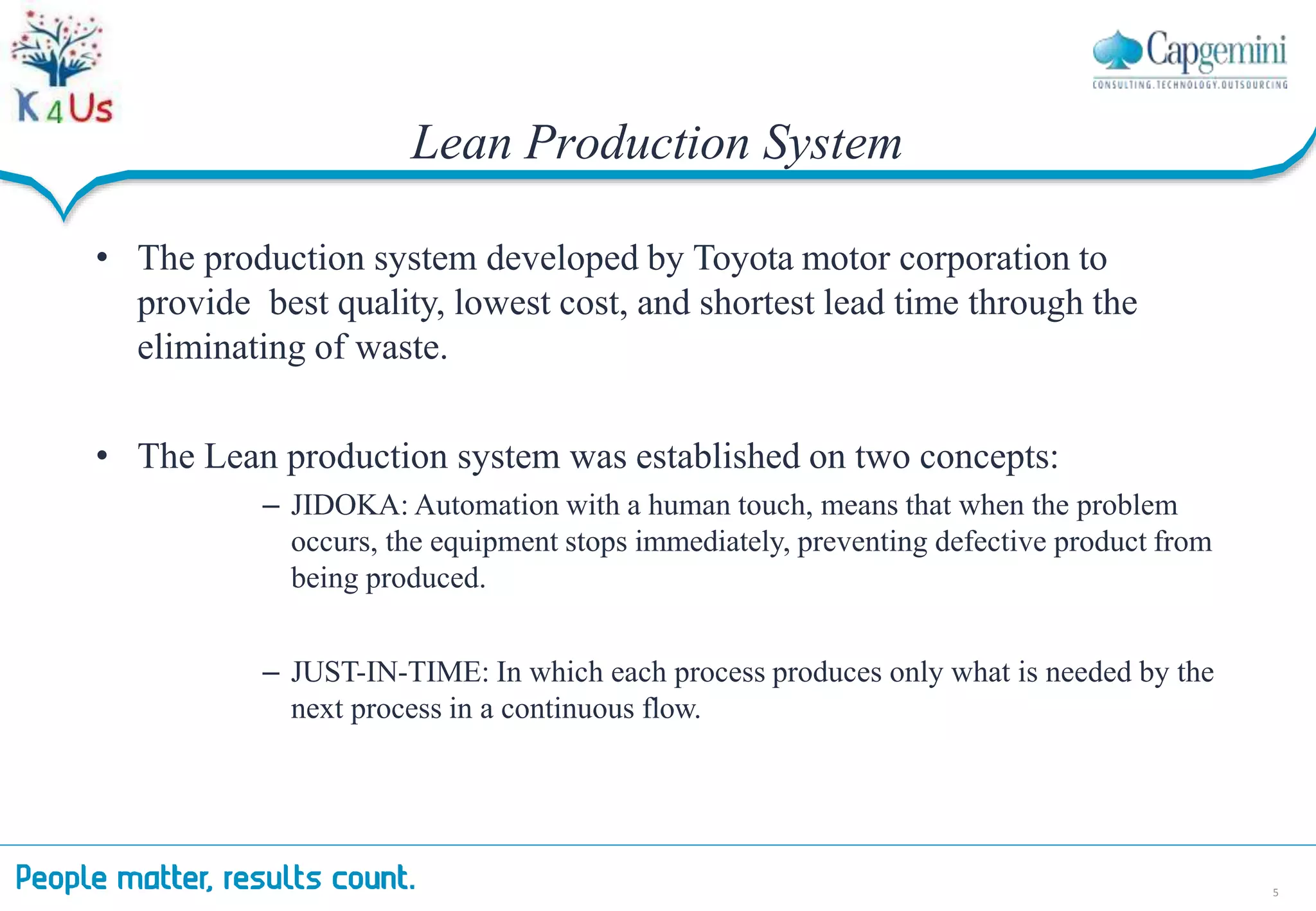

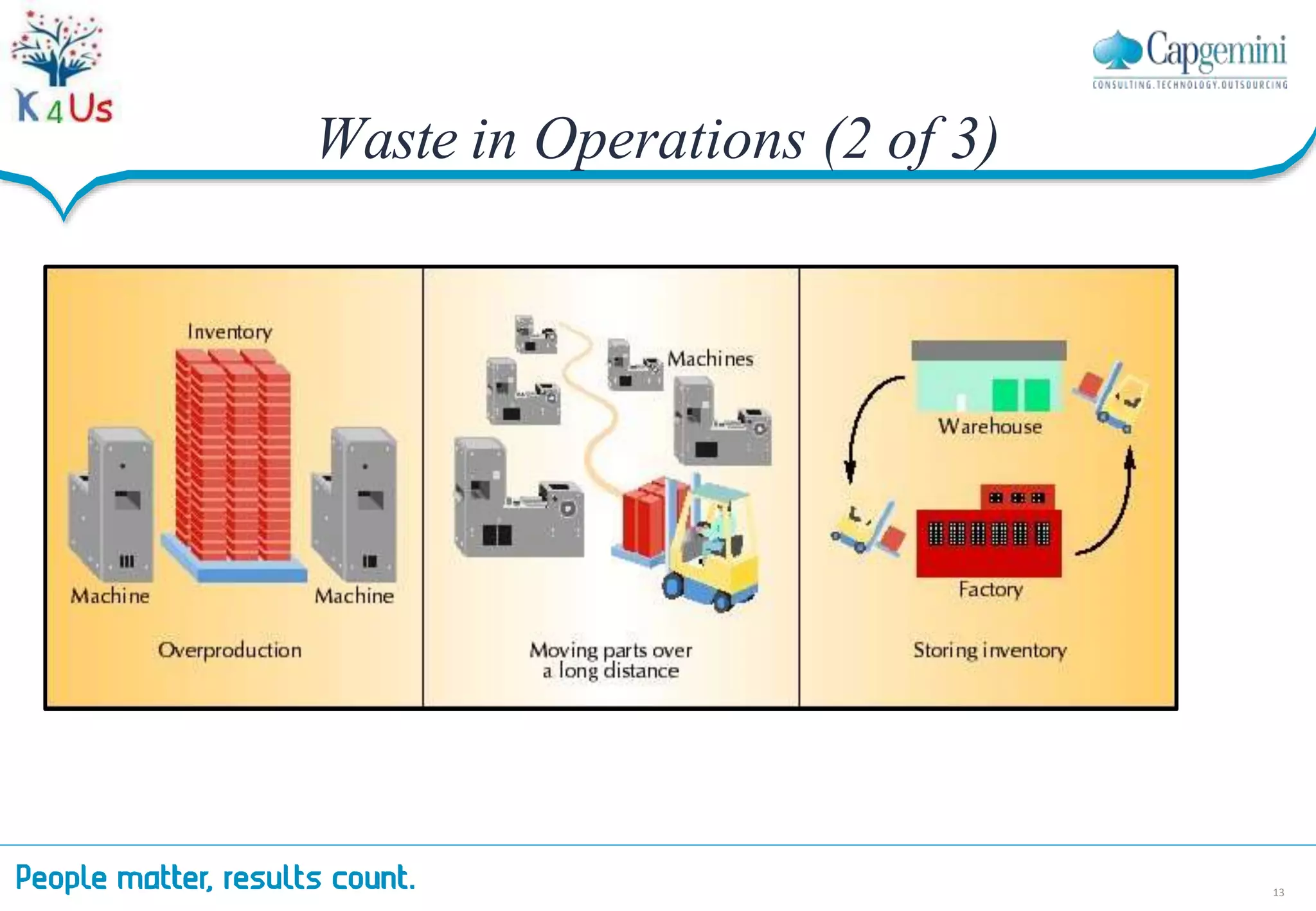

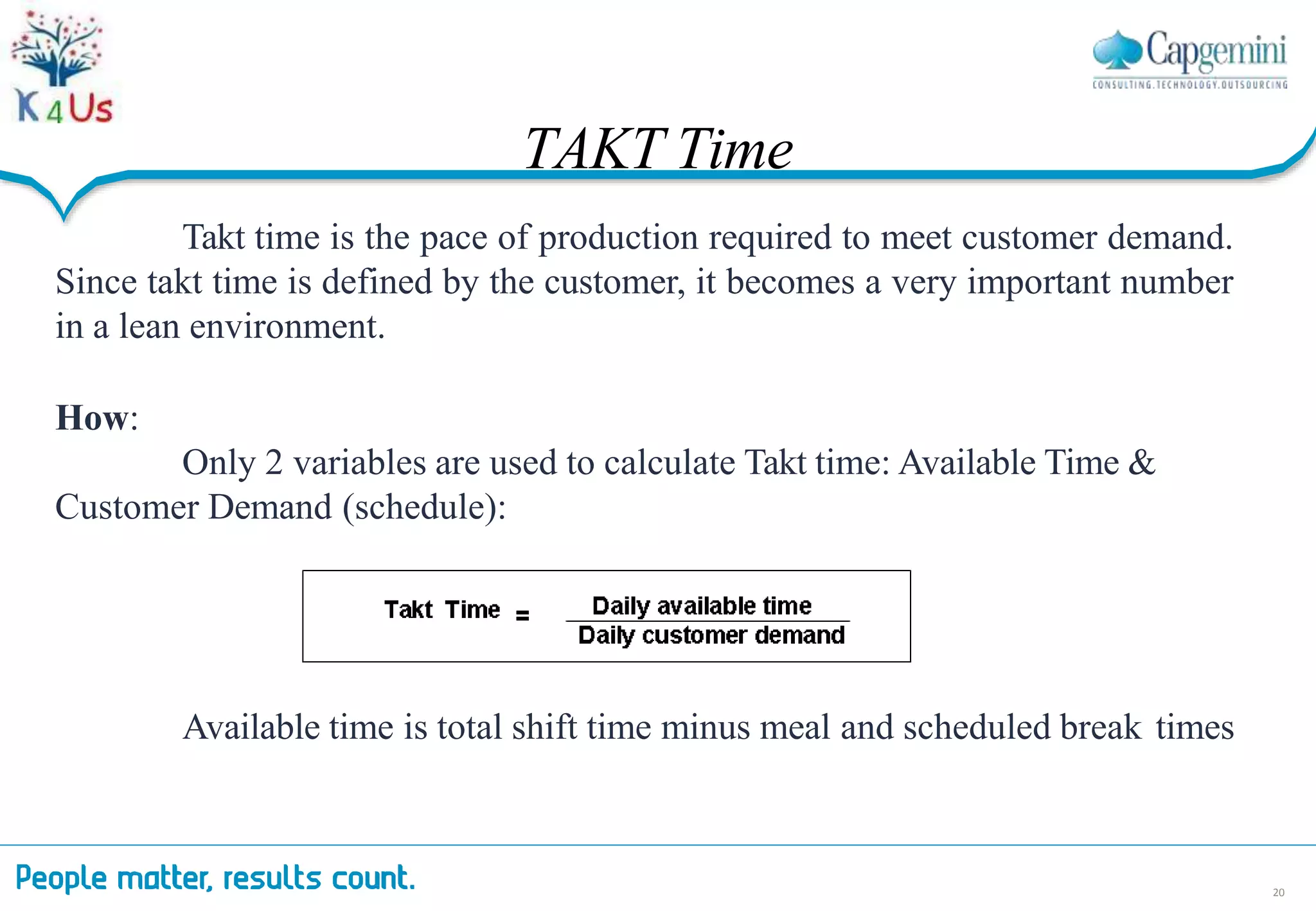

The document discusses key aspects of lean production and the Toyota Production System. It describes how lean focuses on eliminating waste through just-in-time production and continuous flow. The Toyota Production System aims to provide the best quality, lowest cost, and shortest lead time. It establishes two main concepts: Jidoka, which automates processes to stop defects, and Just-in-Time production to create flow without excess inventory between steps.