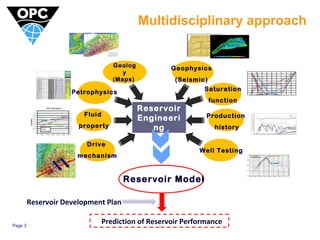

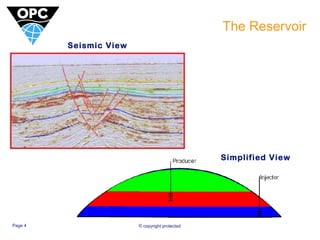

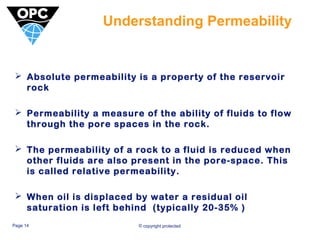

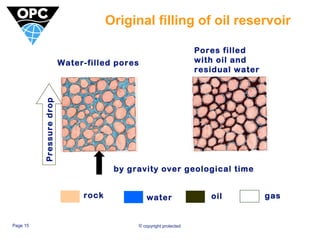

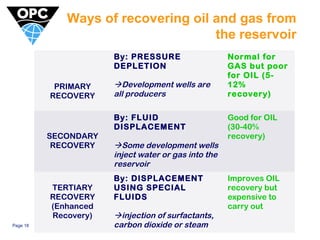

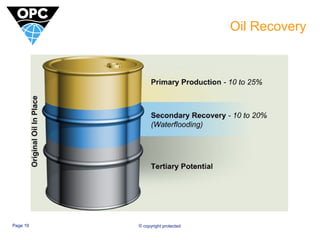

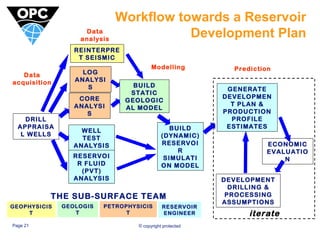

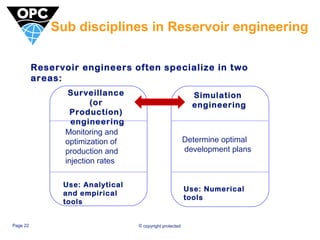

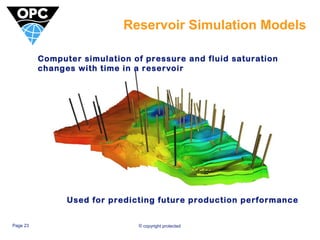

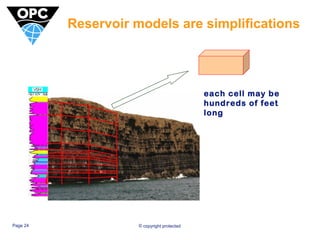

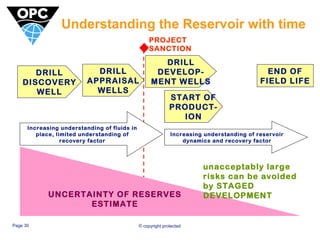

The document provides an introduction to reservoir engineering, focusing on methods and strategies for maximizing oil and gas recovery from reservoirs while minimizing costs. It covers key concepts such as reservoir characterization, fluid properties, recovery mechanisms, and the significance of developing a reservoir plan for economic and regulatory purposes. Additionally, it discusses the role of reservoir engineers and simulation models in predicting production performance over time.