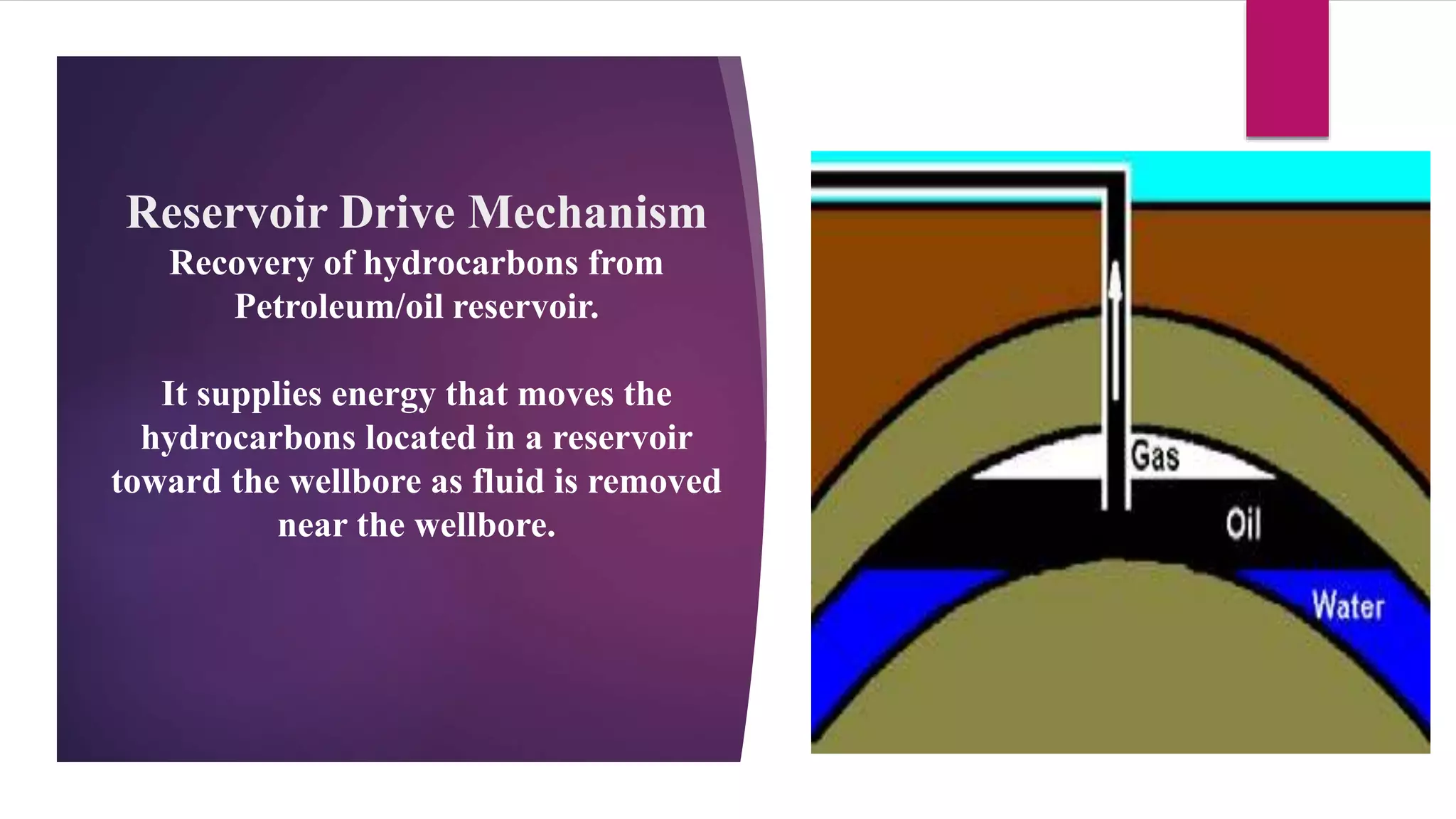

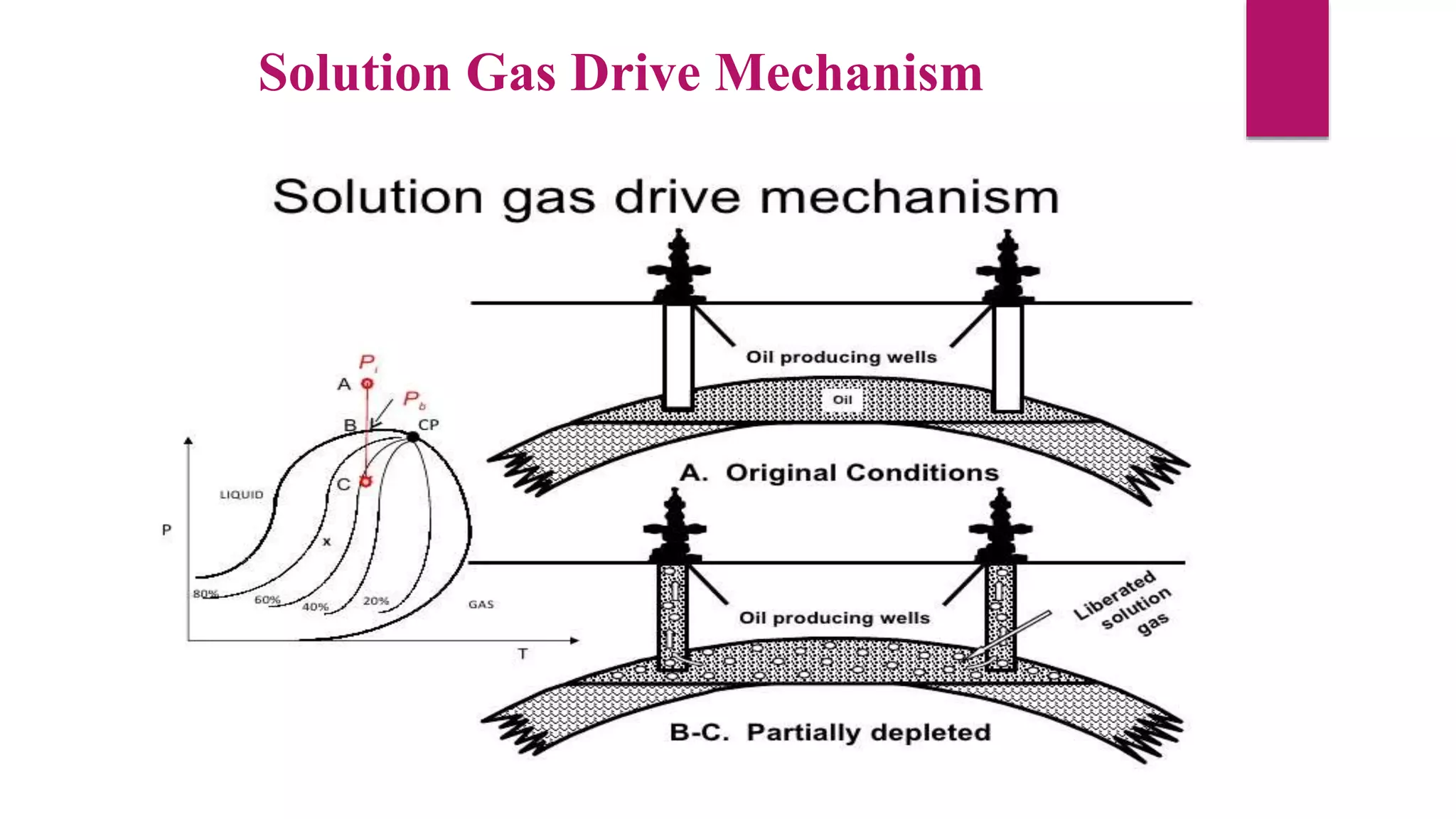

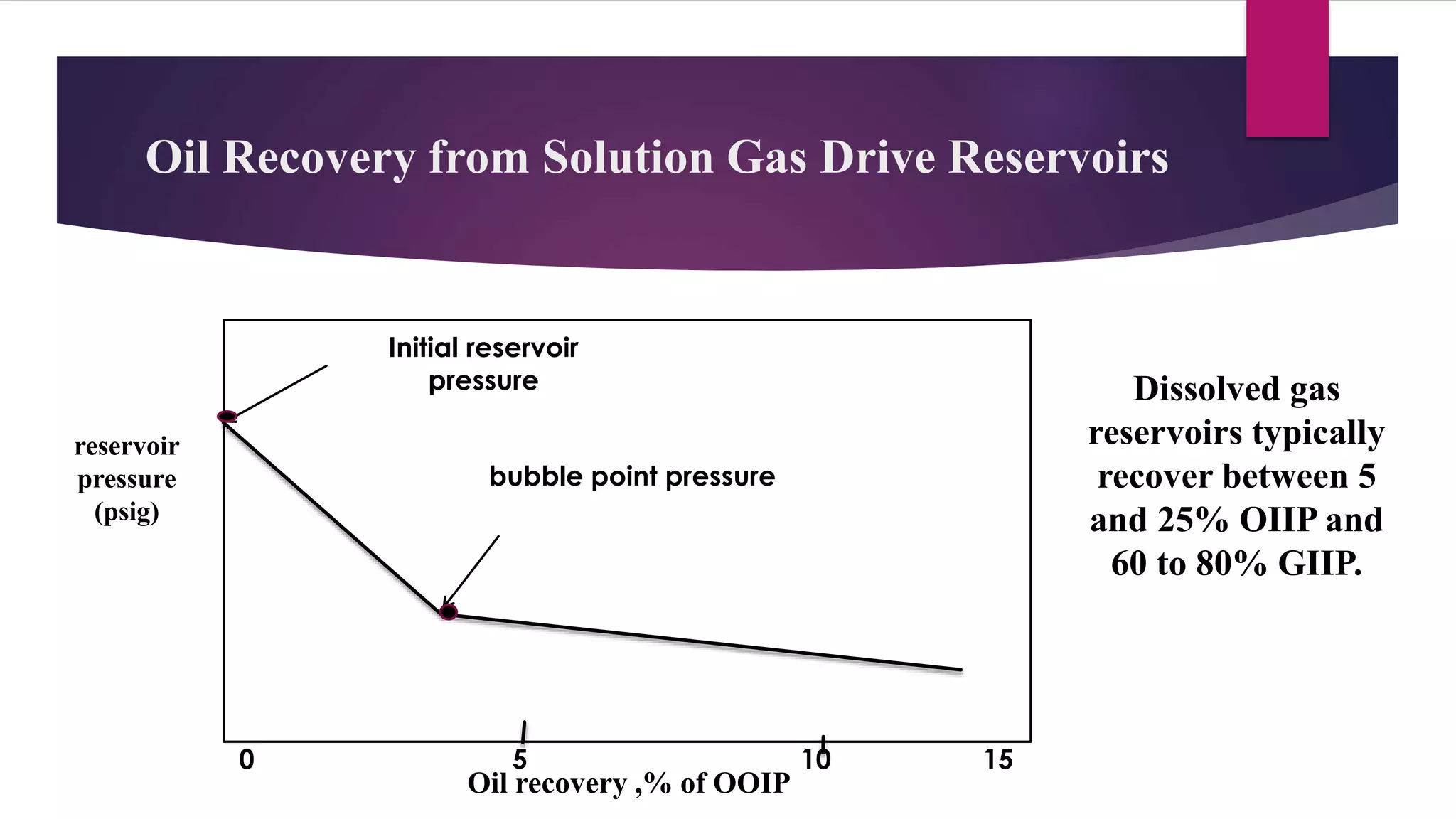

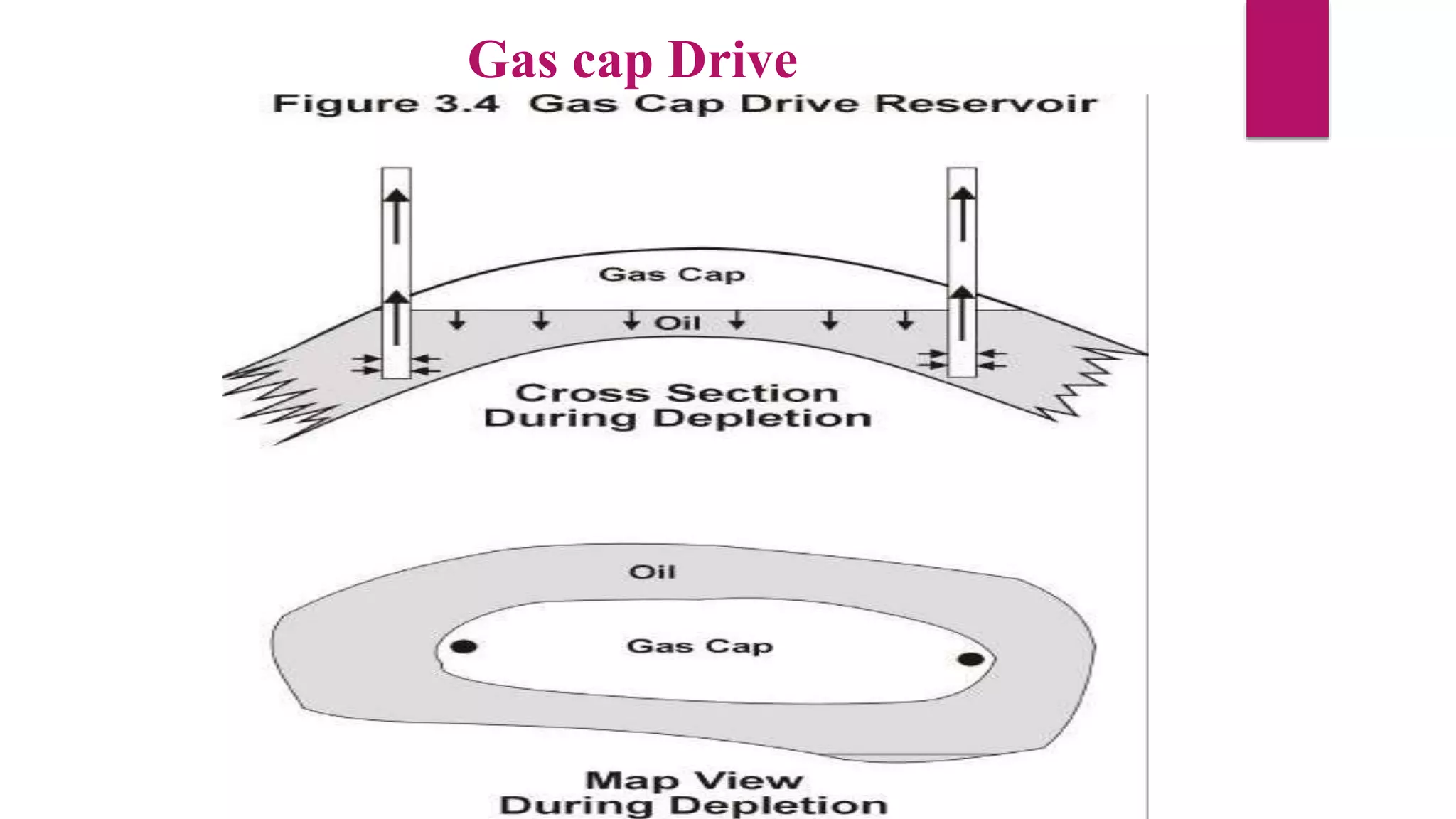

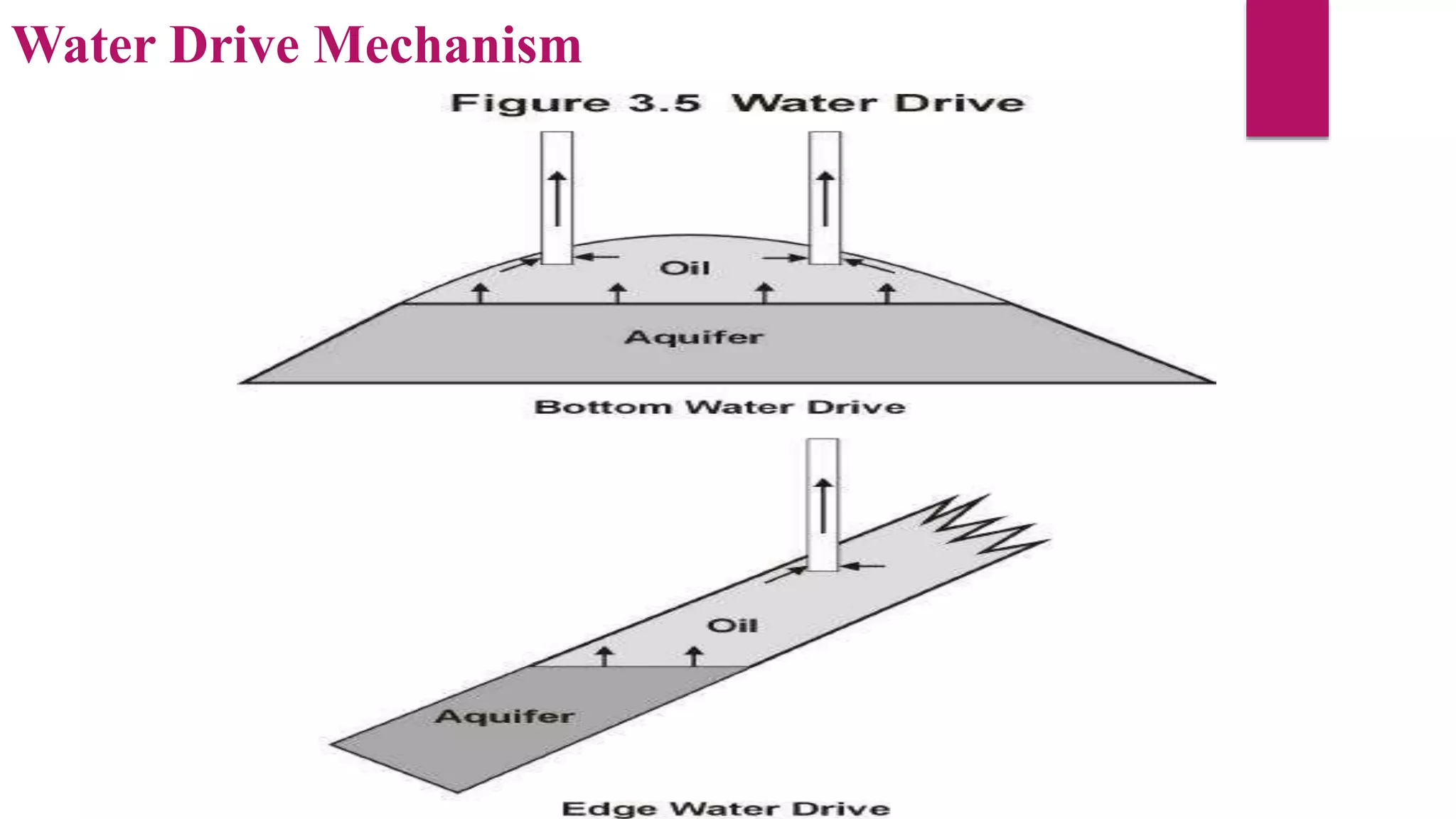

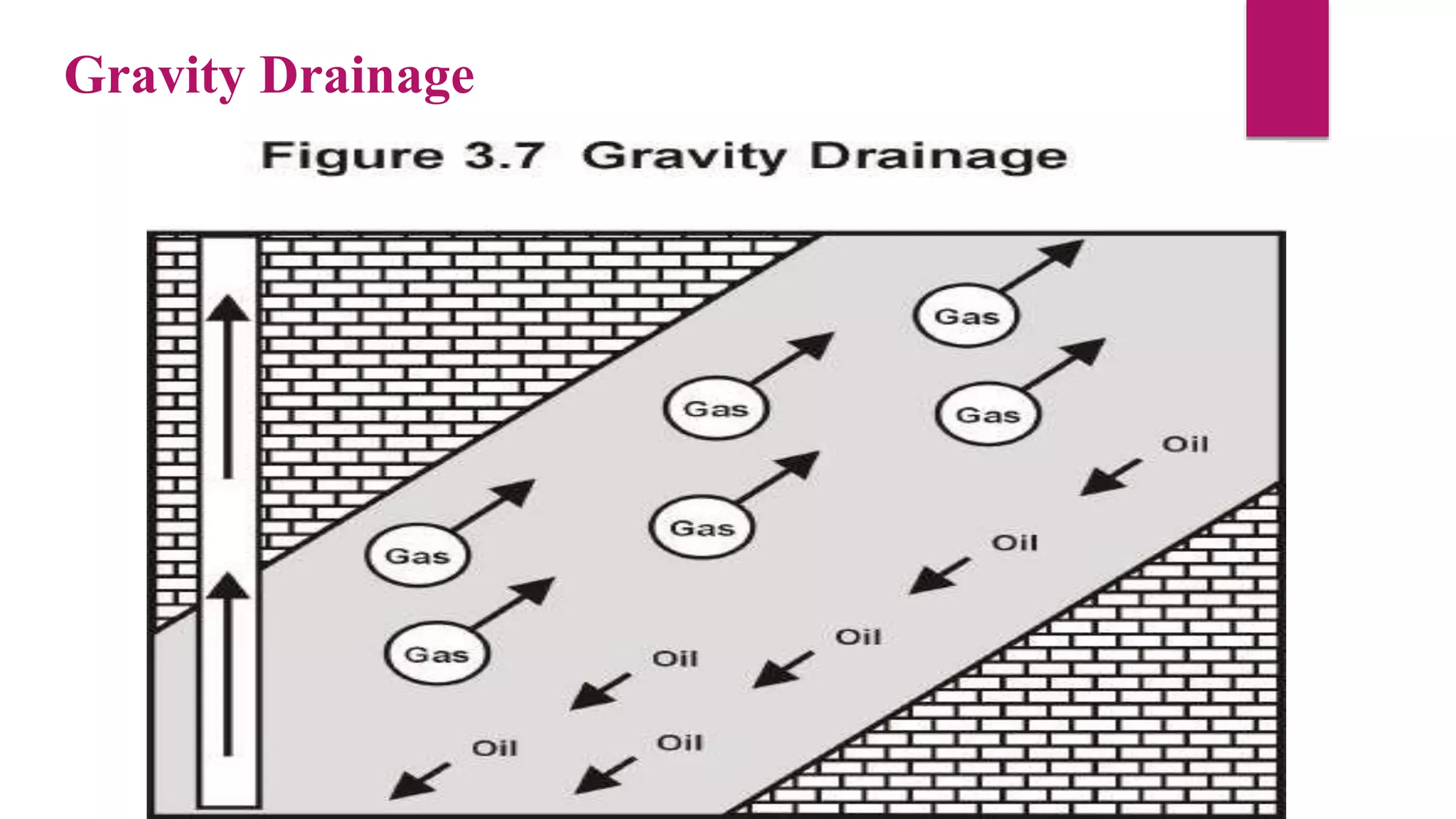

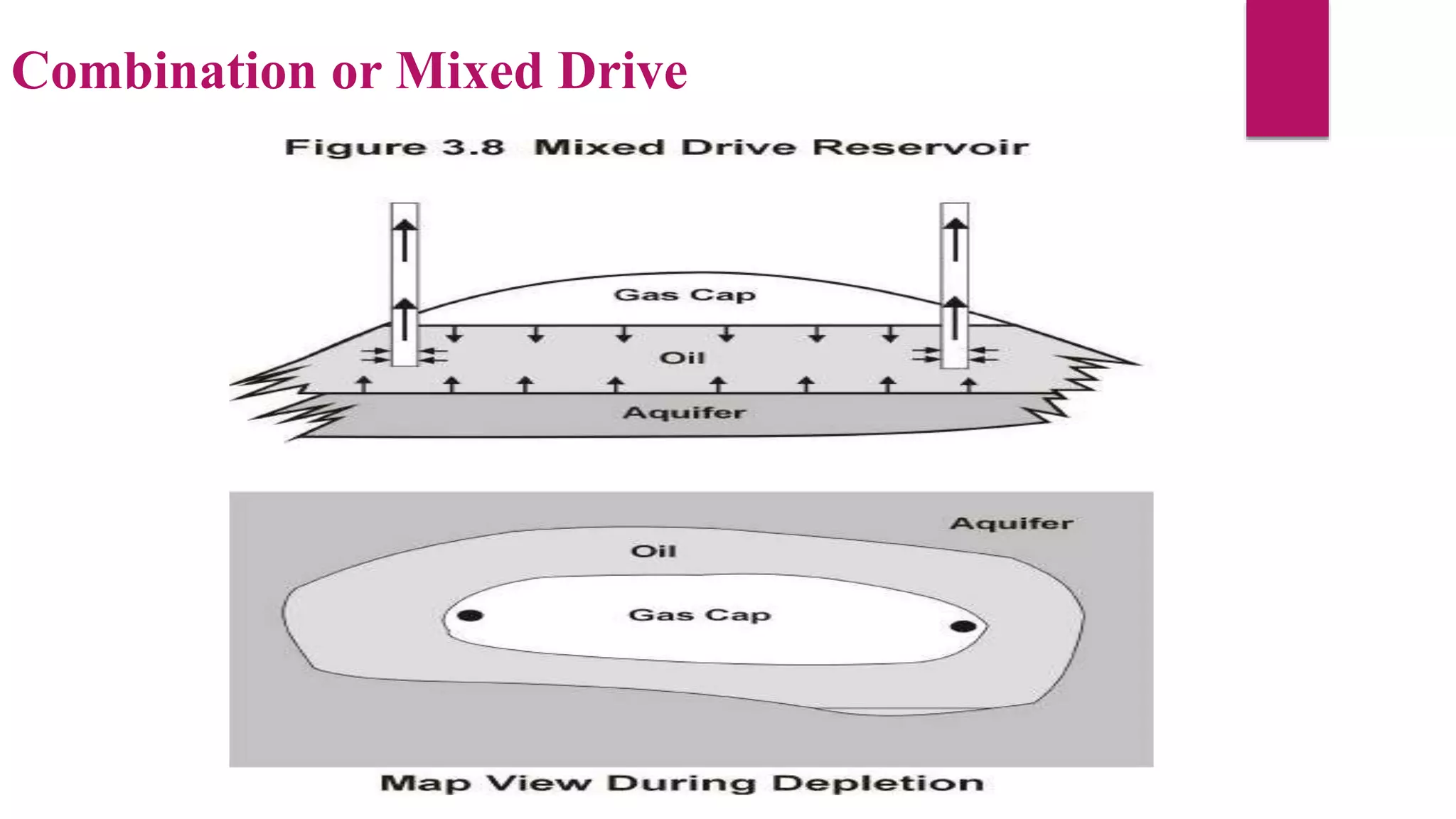

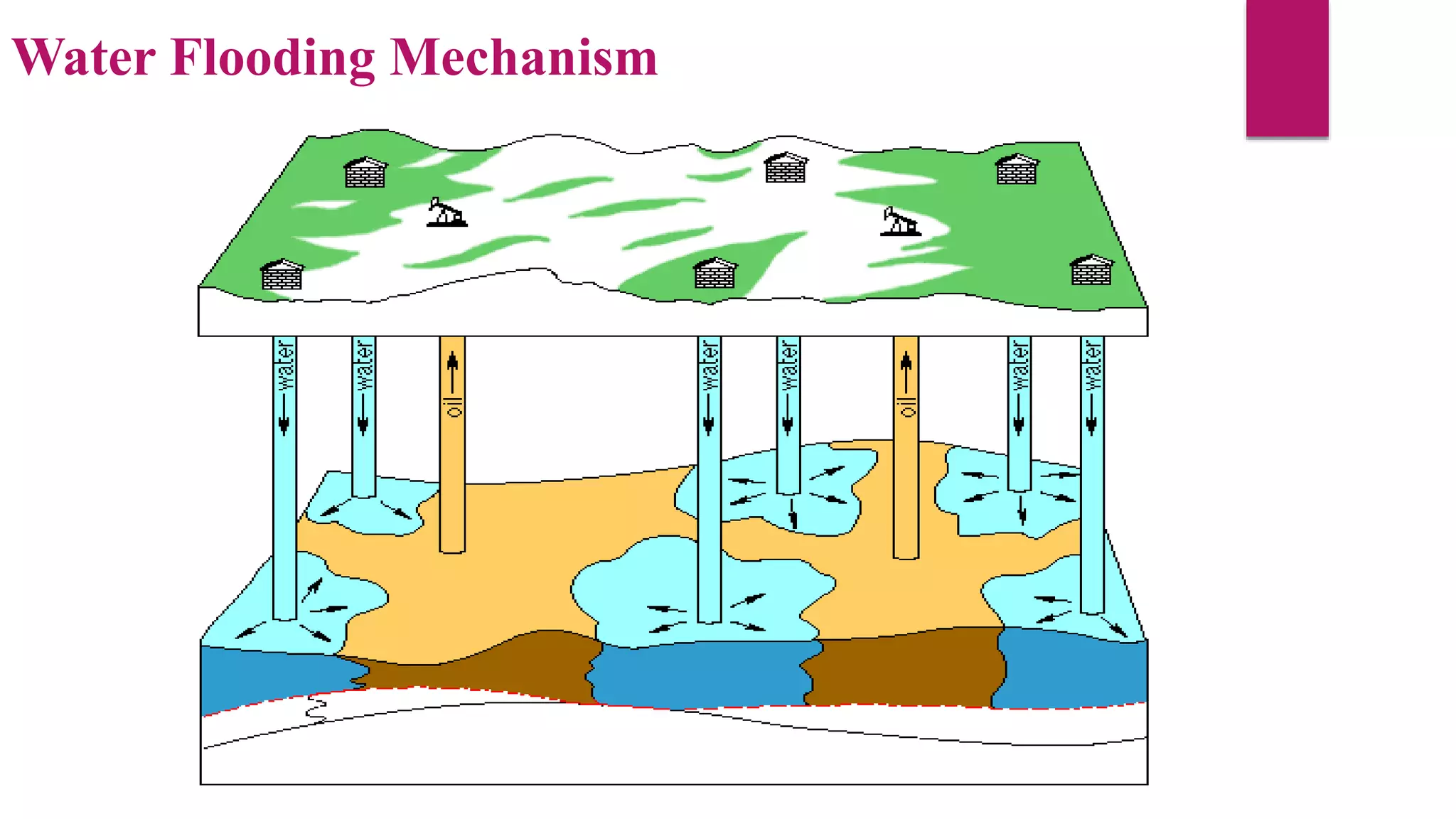

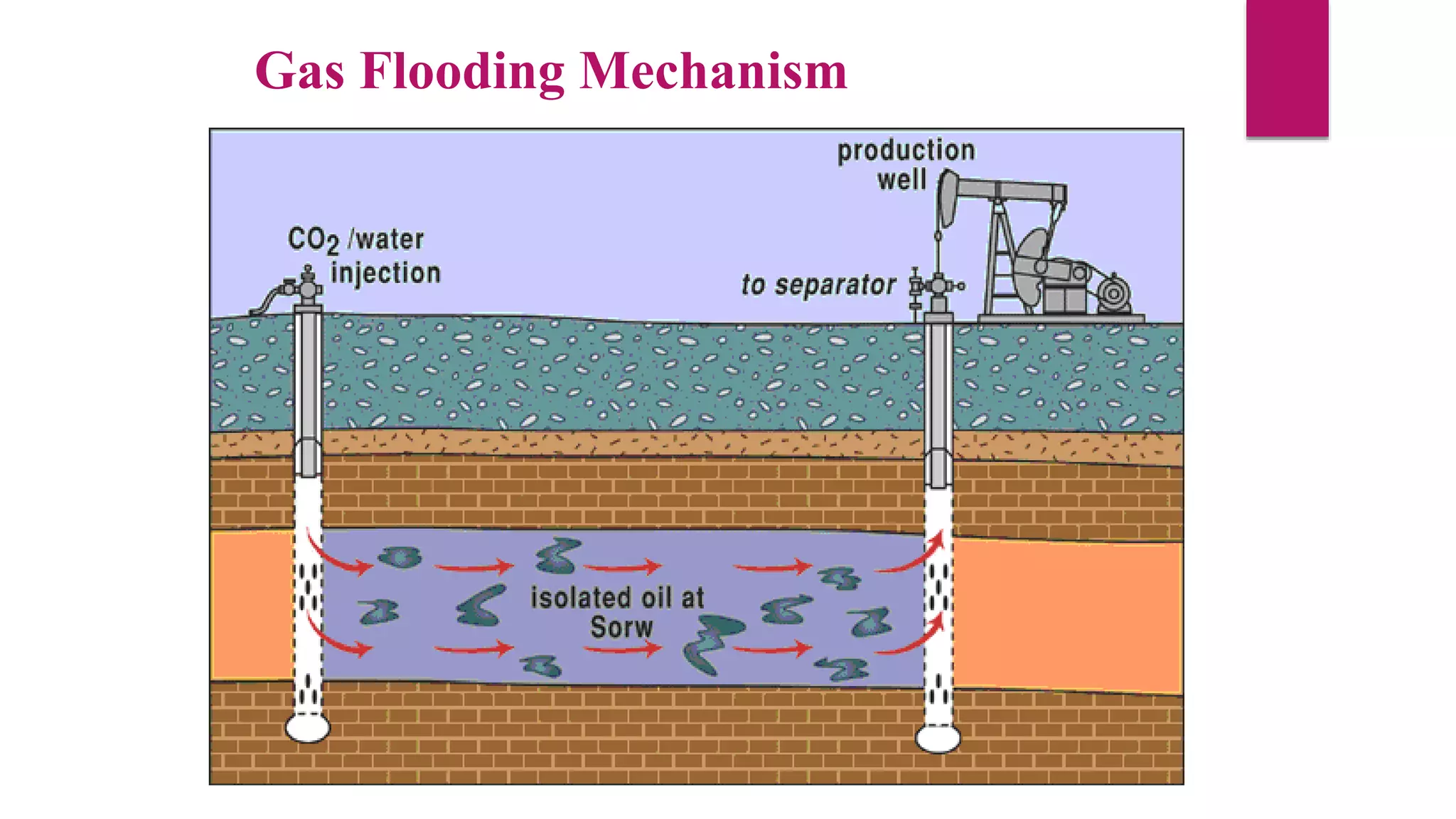

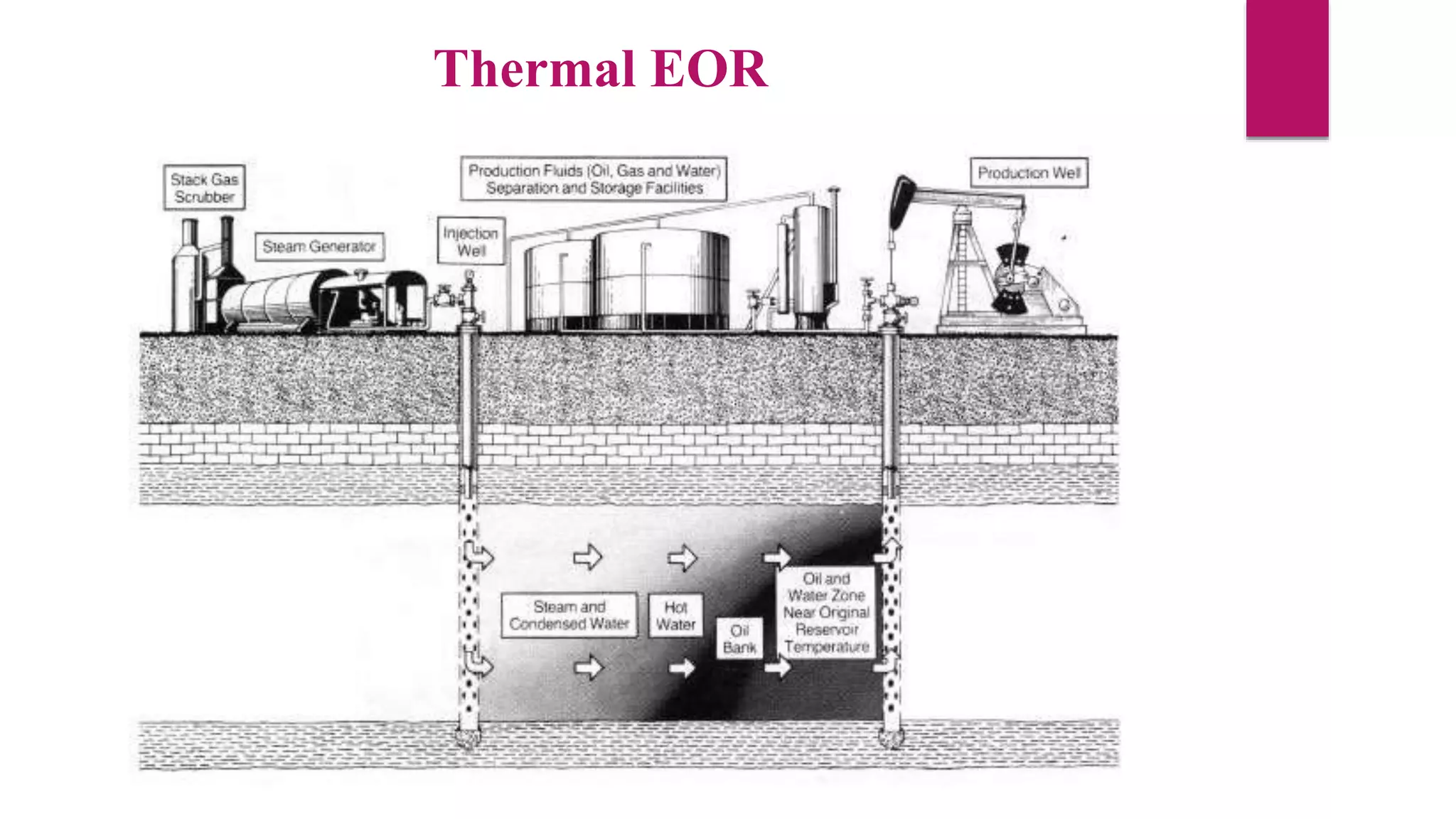

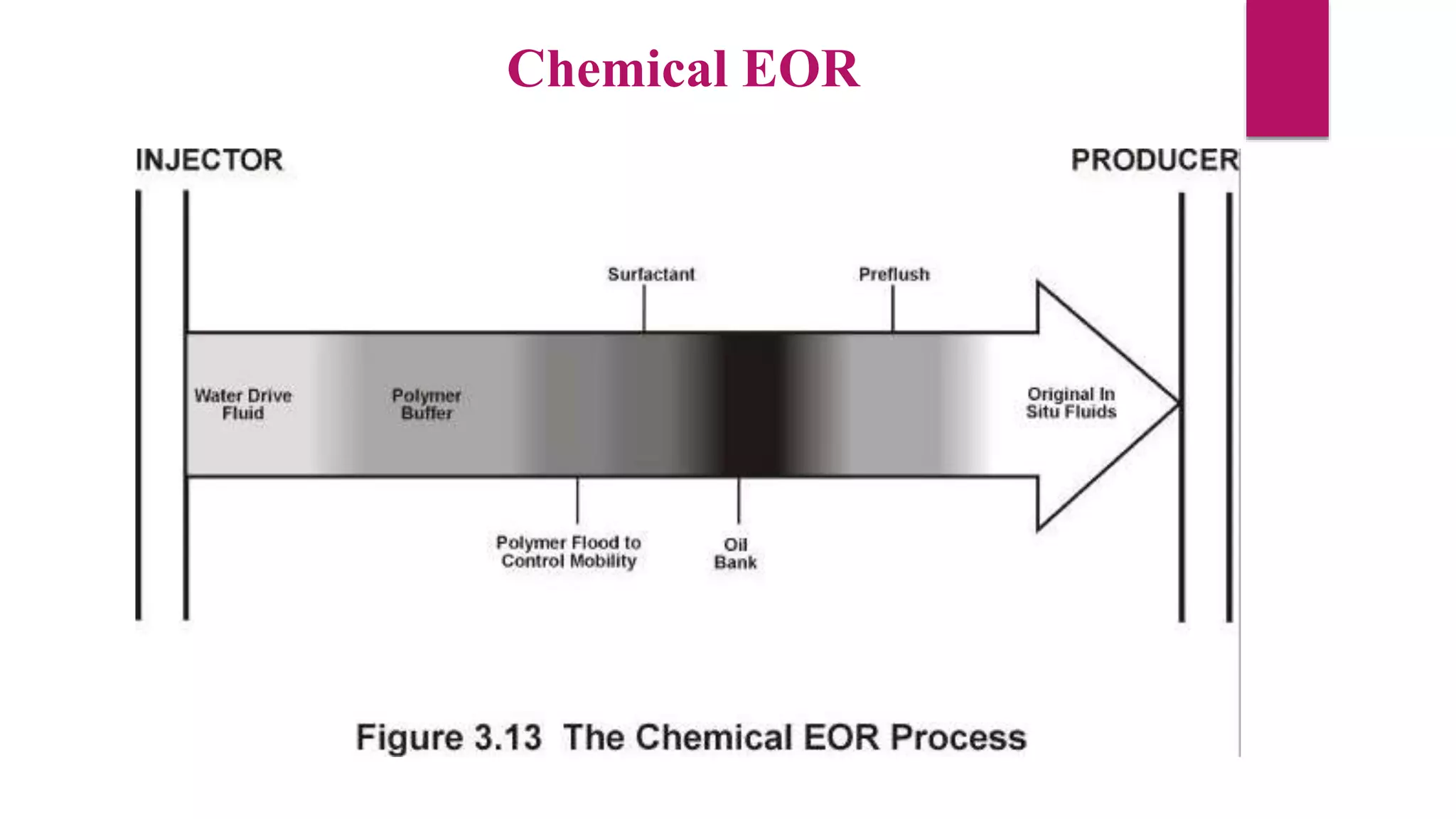

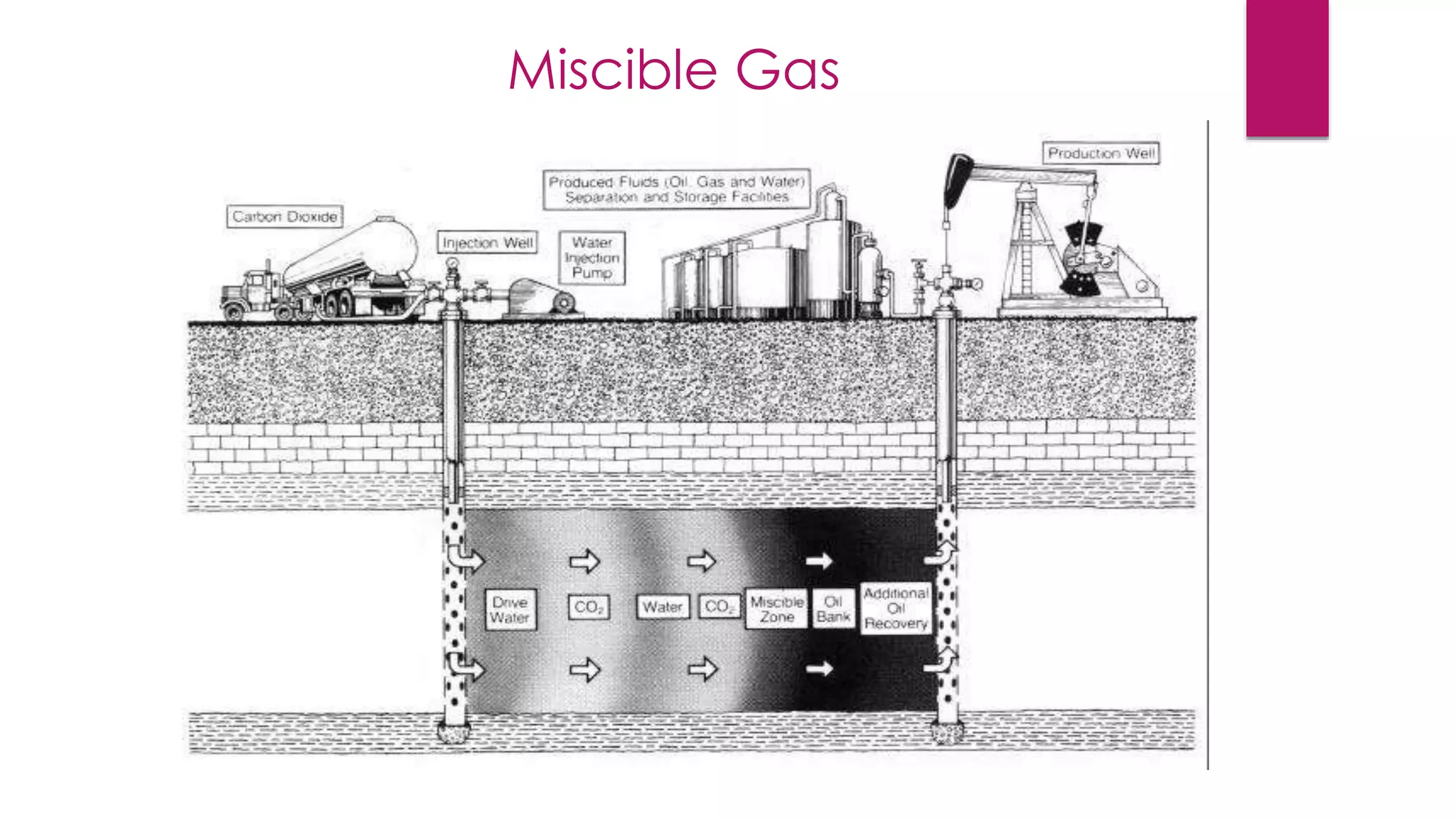

This document discusses various reservoir drive mechanisms used for oil recovery. It begins by defining reservoir drive mechanisms and categorizing recovery stages into primary, secondary, and tertiary. For primary recovery, the drive mechanisms described are solution gas drive, gas cap drive, water drive, and gravity drainage. Secondary recovery involves waterflooding and gasflooding to maintain pressure. Tertiary or EOR recovery discussed includes thermal methods using steam/hot fluids, chemical methods using polymers/surfactants, and miscible gas injection. Infill recovery occurs late in a reservoir's life through additional drilling.