The document is a comprehensive introduction to petroleum engineering authored by John R. Fanchi and Richard L. Christiansen, detailing key concepts such as reservoir management, production performance, and the future of energy. It covers various aspects of the field, including drilling, well logging, and production performance, alongside practical activities and further readings for educational purposes. The book stresses the importance of environmental considerations and economics in relation to petroleum engineering.

![Copyright © 2017 by John Wiley & Sons, Inc. All rights reserved

Published by John Wiley & Sons, Inc., Hoboken, New Jersey

Published simultaneously in Canada

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form

or by any means, electronic, mechanical, photocopying, recording, scanning, or otherwise, except as

permitted under Section 107 or 108 of the 1976 United States Copyright Act, without either the prior

written permission of the Publisher, or authorization through payment of the appropriate per‐copy fee

to the Copyright Clearance Center, Inc., 222 Rosewood Drive, Danvers, MA 01923, (978) 750‐8400,

fax (978) 750‐4470, or on the web at www.copyright.com. Requests to the Publisher for

permission should be addressed to the Permissions Department, John Wiley & Sons, Inc.,

111 River Street, Hoboken, NJ 07030, (201) 748‐6011, fax (201) 748‐6008, or online at

http://www.wiley.com/go/permissions.

Limit of Liability/Disclaimer of Warranty: While the publisher and author have used their best efforts

in preparing this book, they make no representations or warranties with respect to the accuracy or

completeness of the contents of this book and specifically disclaim any implied warranties of

merchantability or fitness for a particular purpose. No warranty may be created or extended by sales

representatives or written sales materials. The advice and strategies contained herein may not be suitable

for your situation. You should consult with a professional where appropriate. Neither the publisher nor

author shall be liable for any loss of profit or any other commercial damages, including but not limited to

special, incidental, consequential, or other damages.

For general information on our other products and services or for technical support, please contact our

Customer Care Department within the United States at (800) 762‐2974, outside the United States at

(317) 572‐3993 or fax (317) 572‐4002.

Wiley also publishes its books in a variety of electronic formats. Some content that appears in print may

not be available in electronic formats. For more information about Wiley products, visit our web site at

www.wiley.com.

Library of Congress Cataloging‐in‐Publication Data:

Names: Fanchi, John R., author. | Christiansen, Richard L. (Richard Lee), author.

Title: Introduction to petroleum engineering / by John R. Fanchi and Richard L. Christiansen.

Description: Hoboken, New Jersey : John Wiley & Sons, Inc., [2017] | Includes bibliographical

references and index.

Identifiers: LCCN 2016019048| ISBN 9781119193449 (cloth) | ISBN 9781119193647 (epdf) |

ISBN 9781119193616 (epub)

Subjects: LCSH: Petroleum engineering.

Classification: LCC TN870 .F327 2017 | DDC 622/.3382–dc23

LC record available at https://lccn.loc.gov/2016019048

Printed in the United States of America

10 9 8 7 6 5 4 3 2 1](https://image.slidesharecdn.com/introductiontopetroleumengineeringbyjohnr-241125084112-ea228c08/75/Introduction-to-Petroleum-Engineering-by-John-R-Fanchi-pdf-3-2048.jpg)

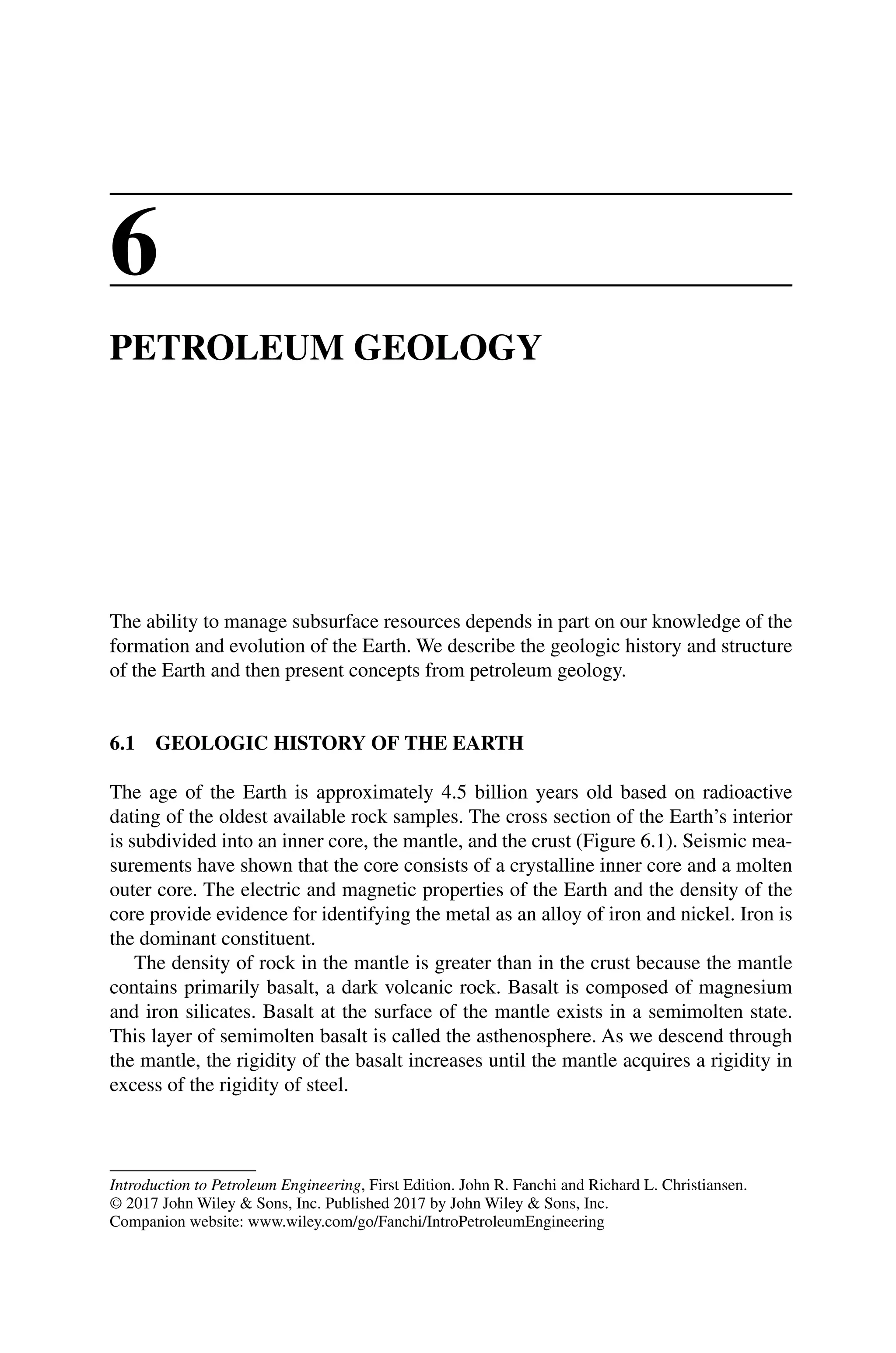

![ACTIVITIES 99

A. What is residual oil saturation (Sorw

)?

B. What is connate water saturation (Swc

)?

C. What is the relative permeability to oil at connate water saturation kro

(Swc

)?

D. What is the relative permeability to water at residual oil saturation krw

(Sorw

)?

E. Assume oil viscosity is 1.30 cp and water viscosity is 0.80 cp. Calculate

mobility ratio for water displacing oil in an oil–water system using the

data in the table and mobility ratio = λ λ µ

Displacing displaced rw orw w

/ / /

= ( )

( )

k S

ro wc o

( )

( / )

k S µ .

5.6 A well is producing oil in a field with 20‐acre well spacing. The oil has vis-

cosity 2.3cp and formation volume factor 1.25RB/STB. The net thickness of

the reservoir is 30ft and the effective permeability is 100md. The well radius is

4.5in. and the well has skin=0. What is the productivity index (PI) of the well

in STB/D/psi?

5.7 A.

Interfacial tension (IFT) σ can be estimated using the Weinaug–Katz vari-

ation of the Macleod–Sugden correlation:

σ σ

ρ ρ

1 4

1

1 4

1

/ /

= = −

= =

∑ ∑

i

N

i

i

N

i i

c c

P x

M

y

M

chi

L

L

V

V

where σ is the interfacial tension (dyne/cm), Pchi

is an empirical parameter

known as the parachor of component i [(dynes/cm)1/4

/(g/cm3

)], ML

is the

molecular weight of liquid phase, MV

is the molecular weight of vapor

phase, ρL

is the liquid phase density (g/cm3

), ρV

is the vapor phase density

(g/cm3

), xi

is the mole fraction of component i in liquid phase, and yi

is the

mole fraction of component i in vapor phase. The parachor of component

i can be estimated using the molecular weight Mi

of component i and the

empirical regression equation (Fanchi, 1990):

P Mi

chi = +

10 0 2 92

. .

This procedure works reasonably well for molecular weights ranging from

100 to 500. Estimate the parachor for octane. The molecular weight of

octane (C8

H18

) is approximately 8 12 18 1 114

* *

+ = , and the density of

octane in the liquid state is approximately 0.7g/cc.

B.

Estimate the contribution σi

of IFT for octane in a liquid mixture with

density 0.63g/cc and molecular weight 104. Assume there is no octane in

the vapor phase and the mole fraction of octane in the liquid phase is 0.9.](https://image.slidesharecdn.com/introductiontopetroleumengineeringbyjohnr-241125084112-ea228c08/75/Introduction-to-Petroleum-Engineering-by-John-R-Fanchi-pdf-113-2048.jpg)

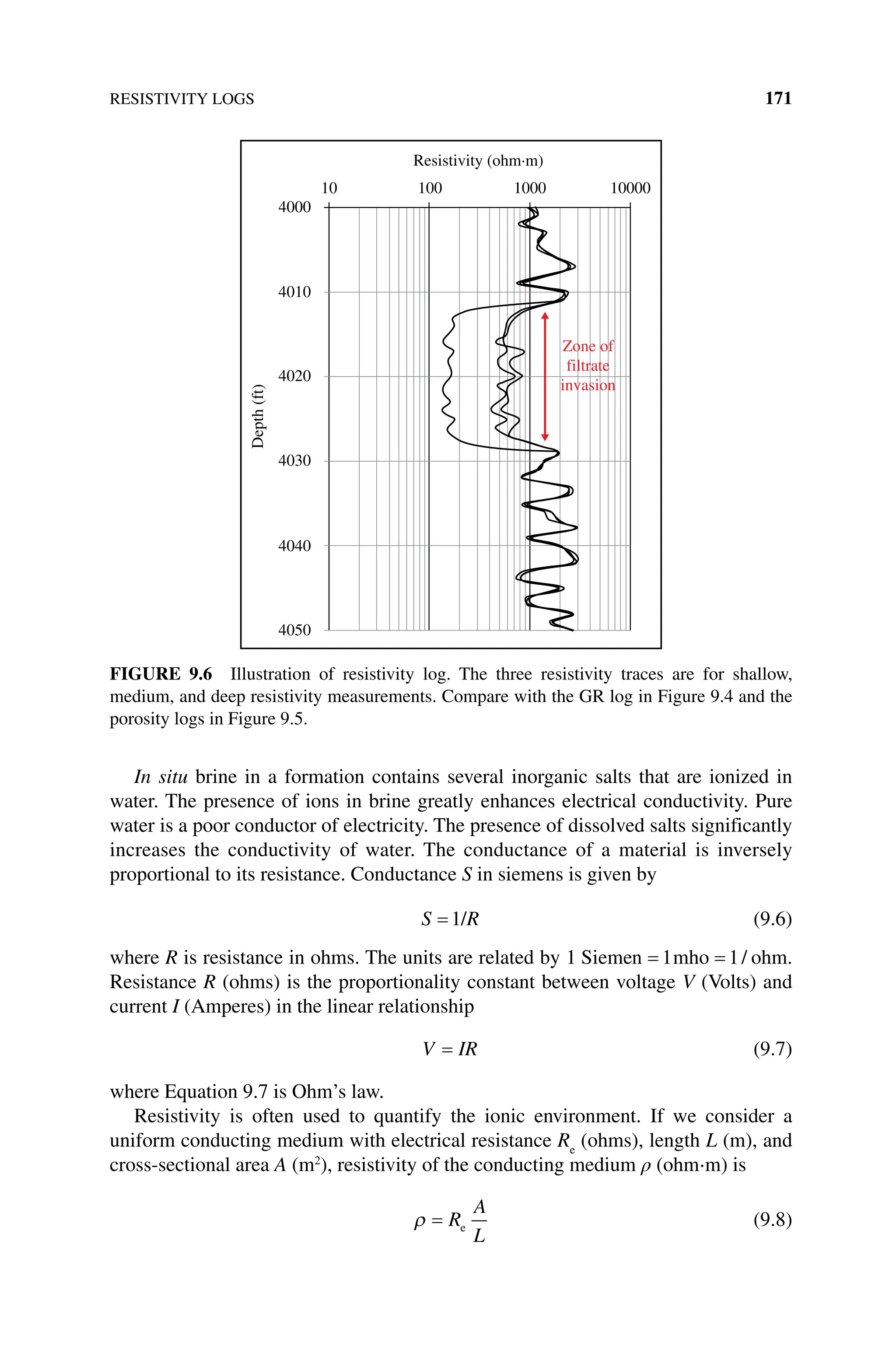

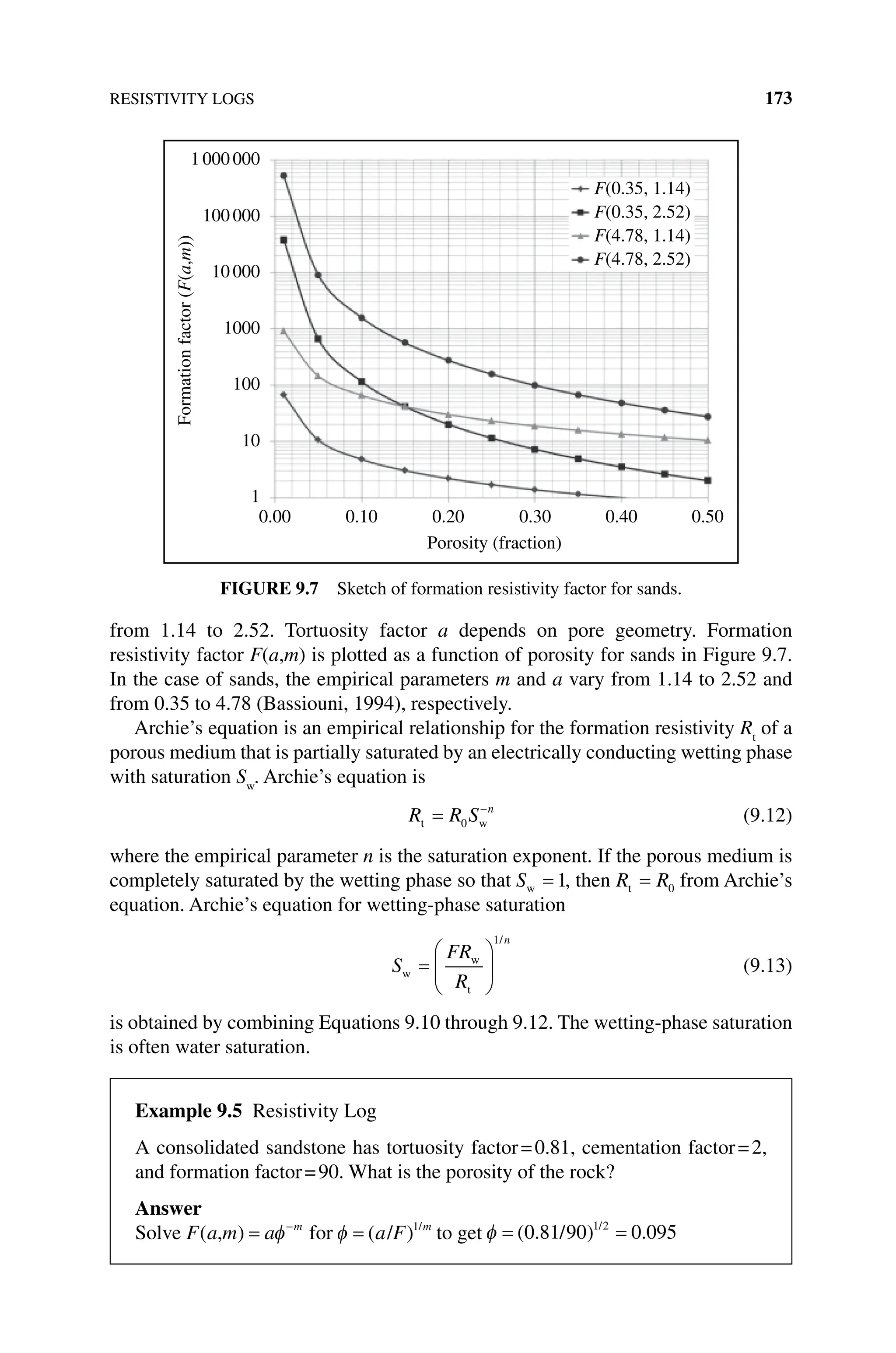

![172 WELL LOGGING

Resistivity ρ (ohm⋅m) is inversely proportional to electrical conductivity σ

(mho/m S/m

= ):

σ ρ

=1/ (9.9)

where1 1 1

S/m siemen/m mho/m

= = .

A high conductivity fluid has low resistivity. By contrast, a low‐conductivity fluid

like oil or gas would have high resistivity. A tool that can measure formation resis-

tivity indicates the type of the fluid that is present in the pore space. Resistivity in

a pore space containing hydrocarbon fluid will be greater than resistivity in the

same pore space containing brine.

The resistivity R0

of a porous material saturated with an ionic solution is equal to

the resistivity Rw

of the ionic solution times the formation resistivity factor F of the

porous material, thus

R FR

0 = w (9.10)

Formation resistivity factor F is sometimes referred to as formation factor. It can be

estimated from the empirical relationship

F a m a m

,

( ) = −

φ (9.11)

where ϕ is porosity, m is cementation exponent, and a is tortuosity factor. The cemen-

tation exponent m depends on the degree of consolidation of the rock and varies

Example 9.4 Ohm’s Law, Resistivity, and Conductivity

A. 0.006C of charge moves through a circuit in 0.1s. What is the current?

B. A 6V battery supports a current in a circuit of 0.06A. Use Ohm’s law to

calculate the resistance of the circuit.

C. Suppose the circuit has a length of 1m and a cross‐sectional area of

1.8m2

. What is the resistivity of the circuit?

D. What is the electrical conductivity of the circuit?

Answer:

A. Current [Ampere]

[Coulomb]

[Second]

C

s

A

= = =

0 006

0 1

0 06

.

.

.

B. Ohm’s law:Voltage V I R

( ) = × = ( )× ( )

current resistance A ohm orV IR

= .

Calculate / 6 V/ 6 A ohm

R V I

= = =

0 0 100

.

C. ρ = = = ⋅

R

A

L

e ohm

m

m

ohm m

100

1 8

1

180

2

.

D. σ

ρ

= =

⋅

= =

1 1

180

0 0056 5 6

ohm m

mho/m mmho/m

. . where mmho=

milli‐mho](https://image.slidesharecdn.com/introductiontopetroleumengineeringbyjohnr-241125084112-ea228c08/75/Introduction-to-Petroleum-Engineering-by-John-R-Fanchi-pdf-184-2048.jpg)

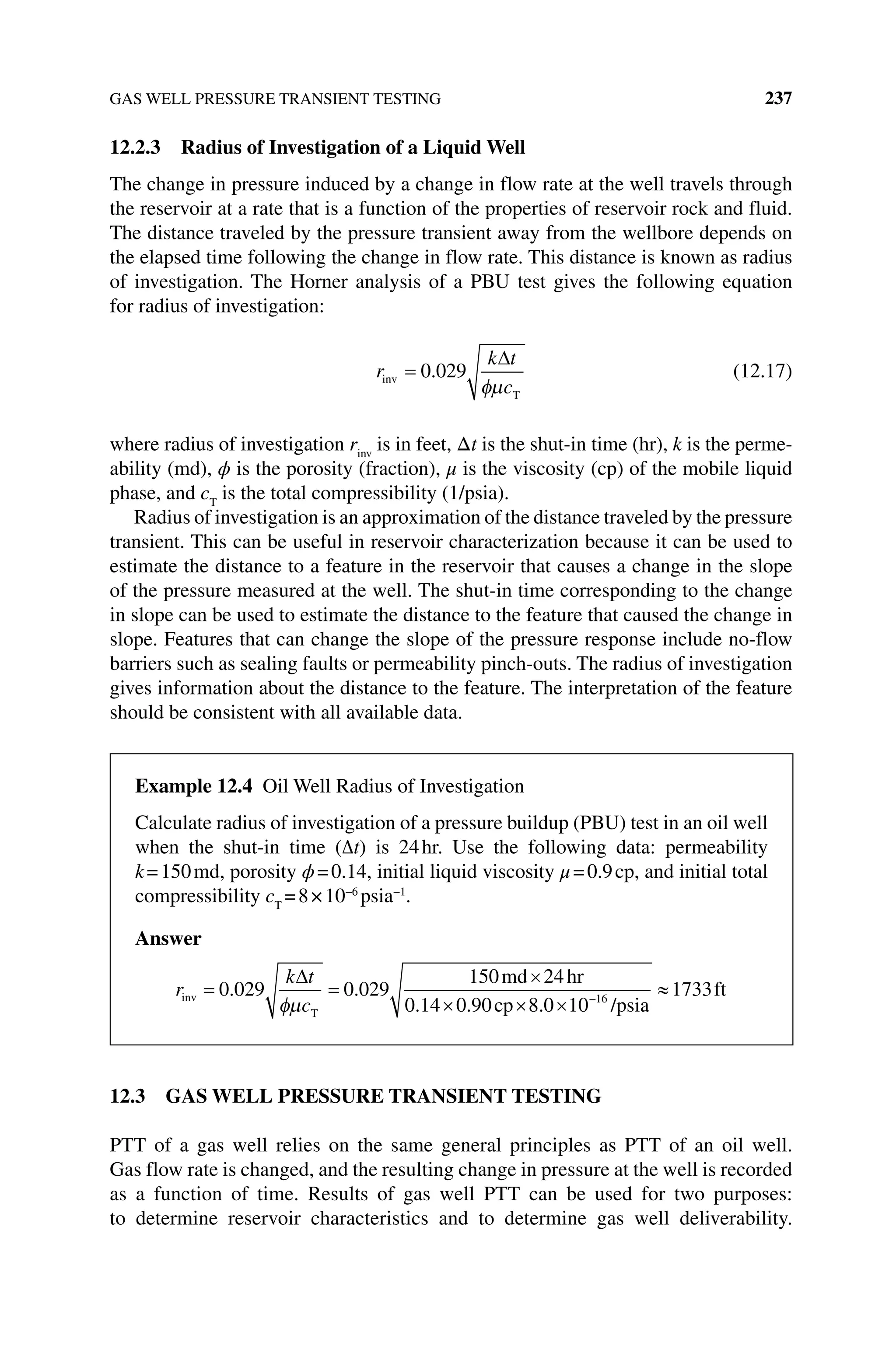

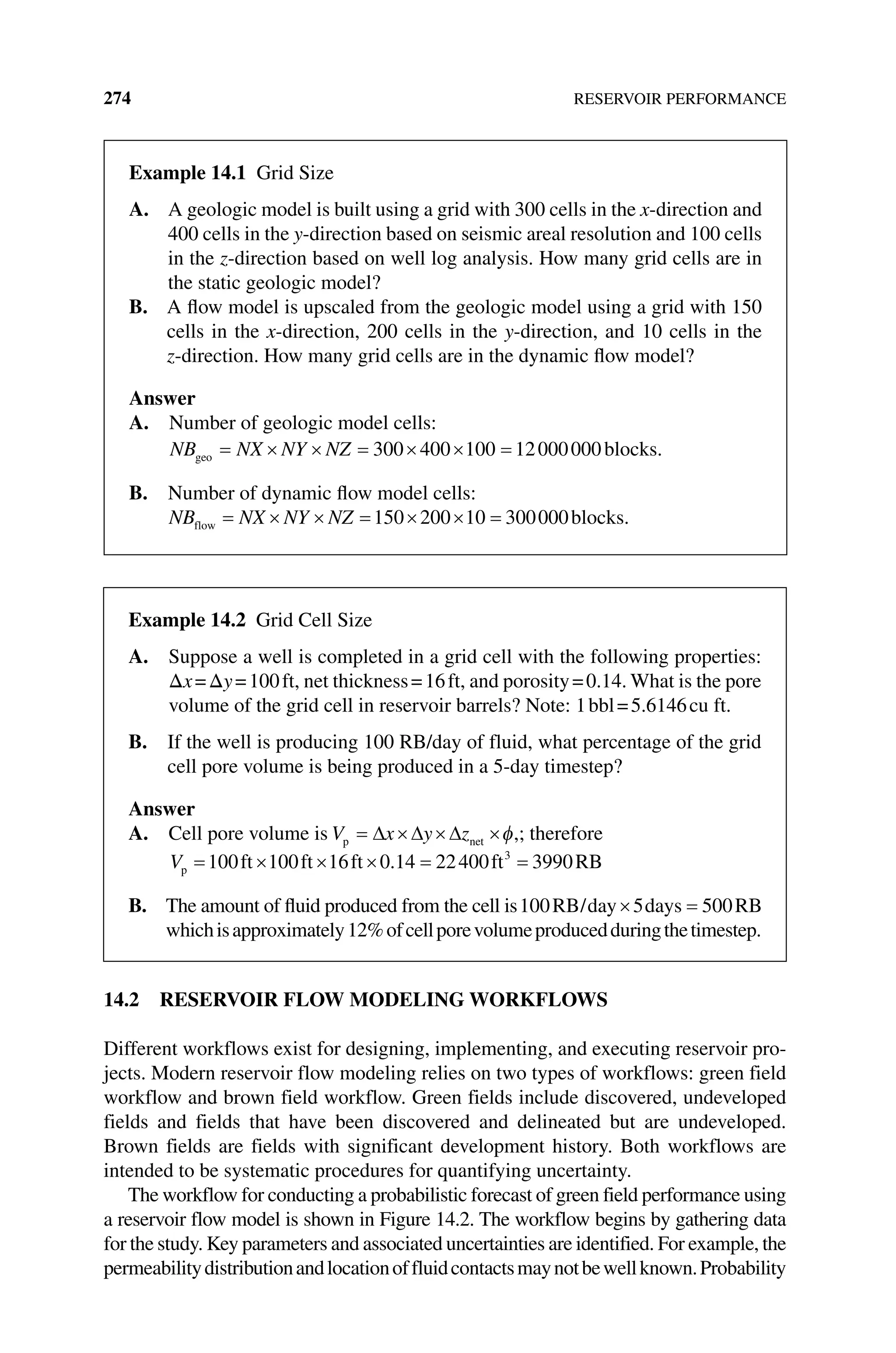

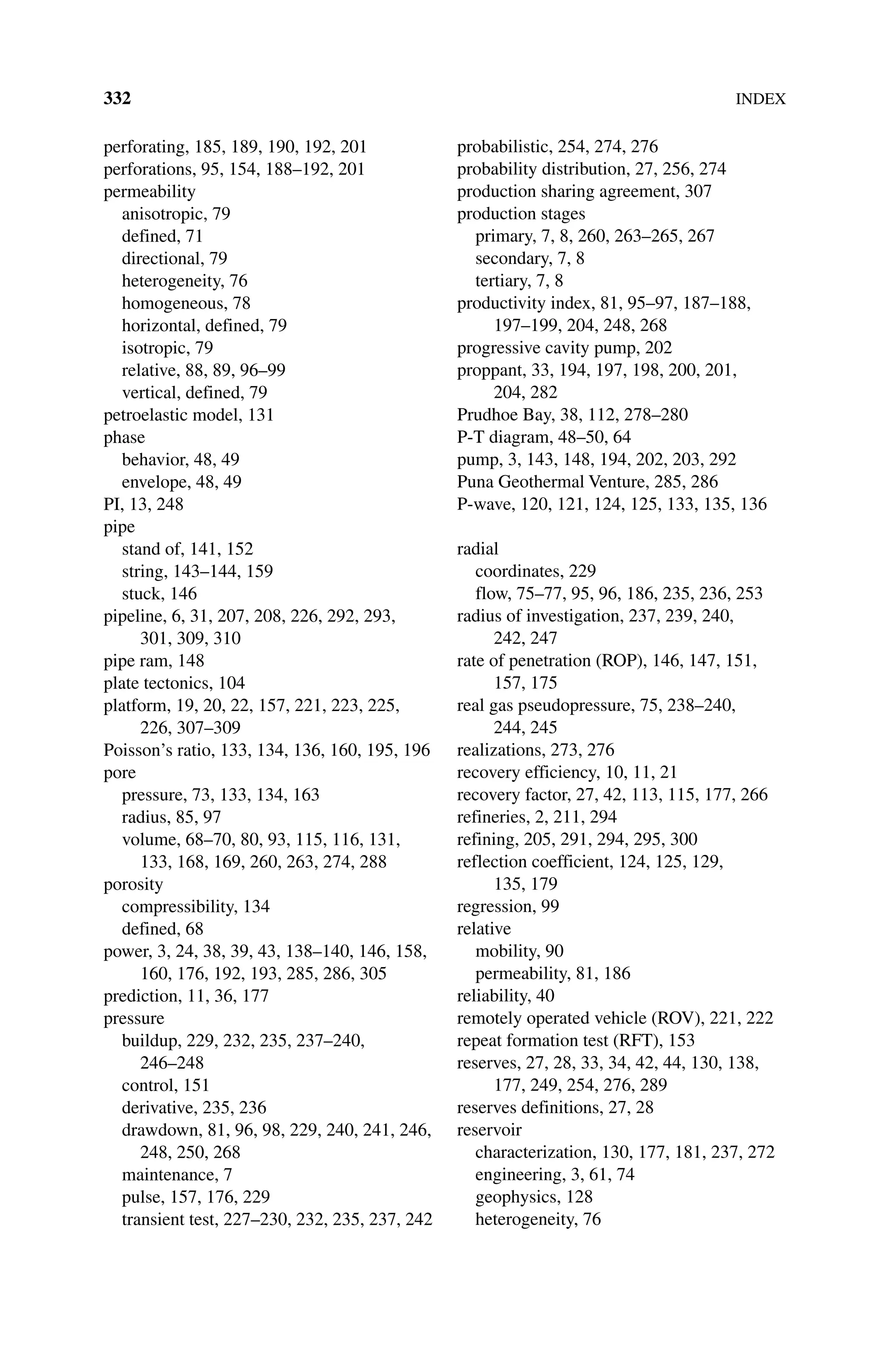

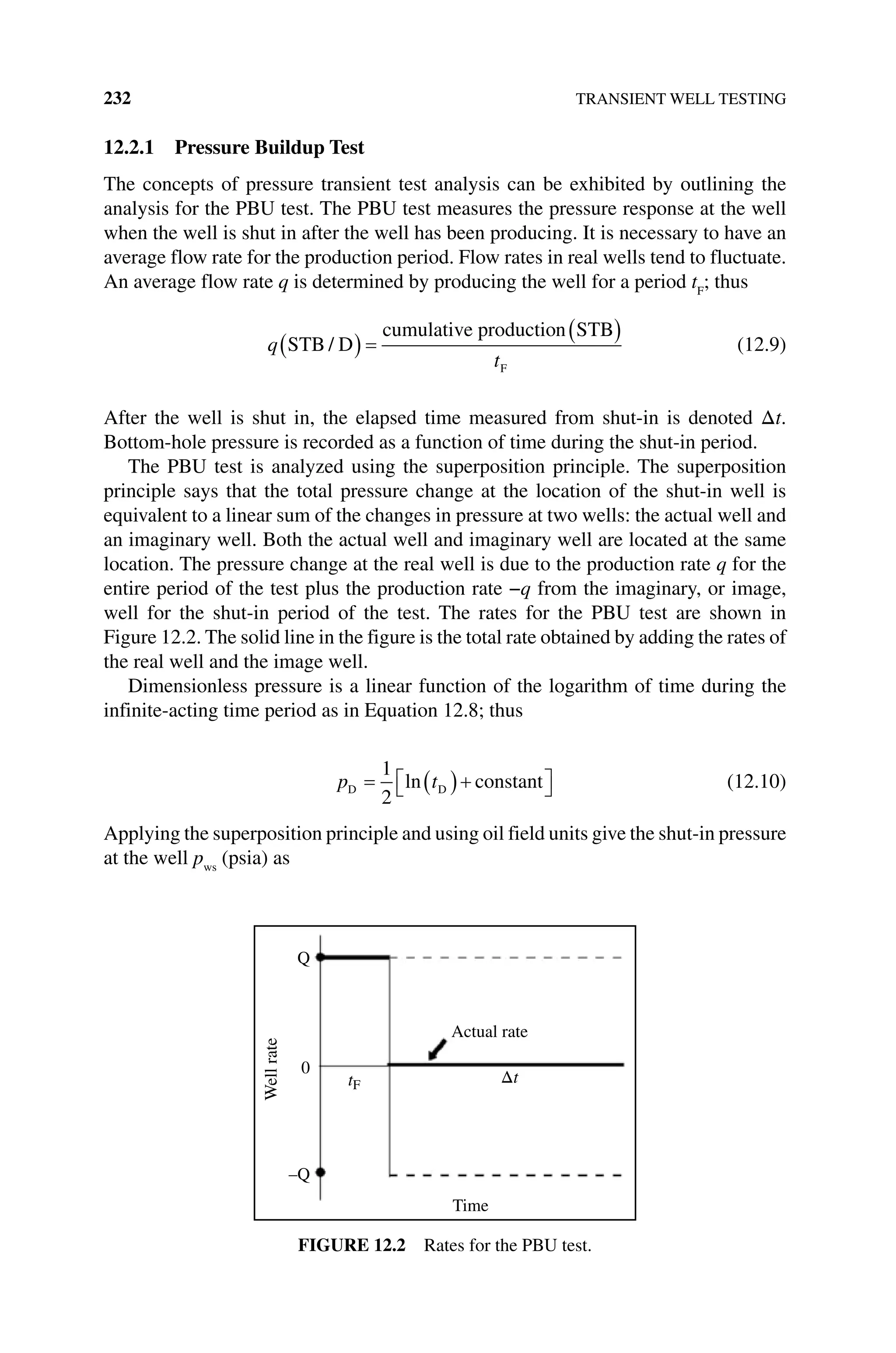

![OIL WELL PRESSURE TRANSIENT TESTING 233

p p

qB

kh

p t t p t

ws i D F D D D

141 2

. (12.11)

where pi

is the initial reservoir pressure (psia), q is the stabilized flow rate (STB/D),

B is the formation volume factor (RB/STB), μ is the viscosity (cp), k is the

permeability (md), and h is the net thickness (ft). The term p t t

D F D

( )

[ ] is

dimensionless pressure evaluated at dimensionless time [ ]

t t

F D, and the term

pD

(ΔtD

) is dimensionless pressure evaluated at dimensionless time ΔtD

. Dimensionless

pressure in Equation 12.11 is replaced by Equation 12.10 to obtain

p p m t

ws i H

log (12.12)

where tH

is the dimensionless Horner time:

t

t t

t

H

F

(12.13)

The hour is the unit of both times tF

,Δt to be consistent with the unit of time used in

the dimensionless time calculation. The variable m is given by

m

qB

kh

162 6

. (12.14)

The unit of m is psia per log cycle when pressure is in psia, q is stabilized flow rate

(STB/D), B is formation volume factor (RB/STB), μ is viscosity (cp), k is perme-

ability (md), and h is net thickness (ft). The concept of log cycle is clarified later.

Equation 12.12 is the equation of a straight line if we plot pws

versus the logarithm

of Horner time on a semilogarithmic plot. The slope of the straight line is −m.

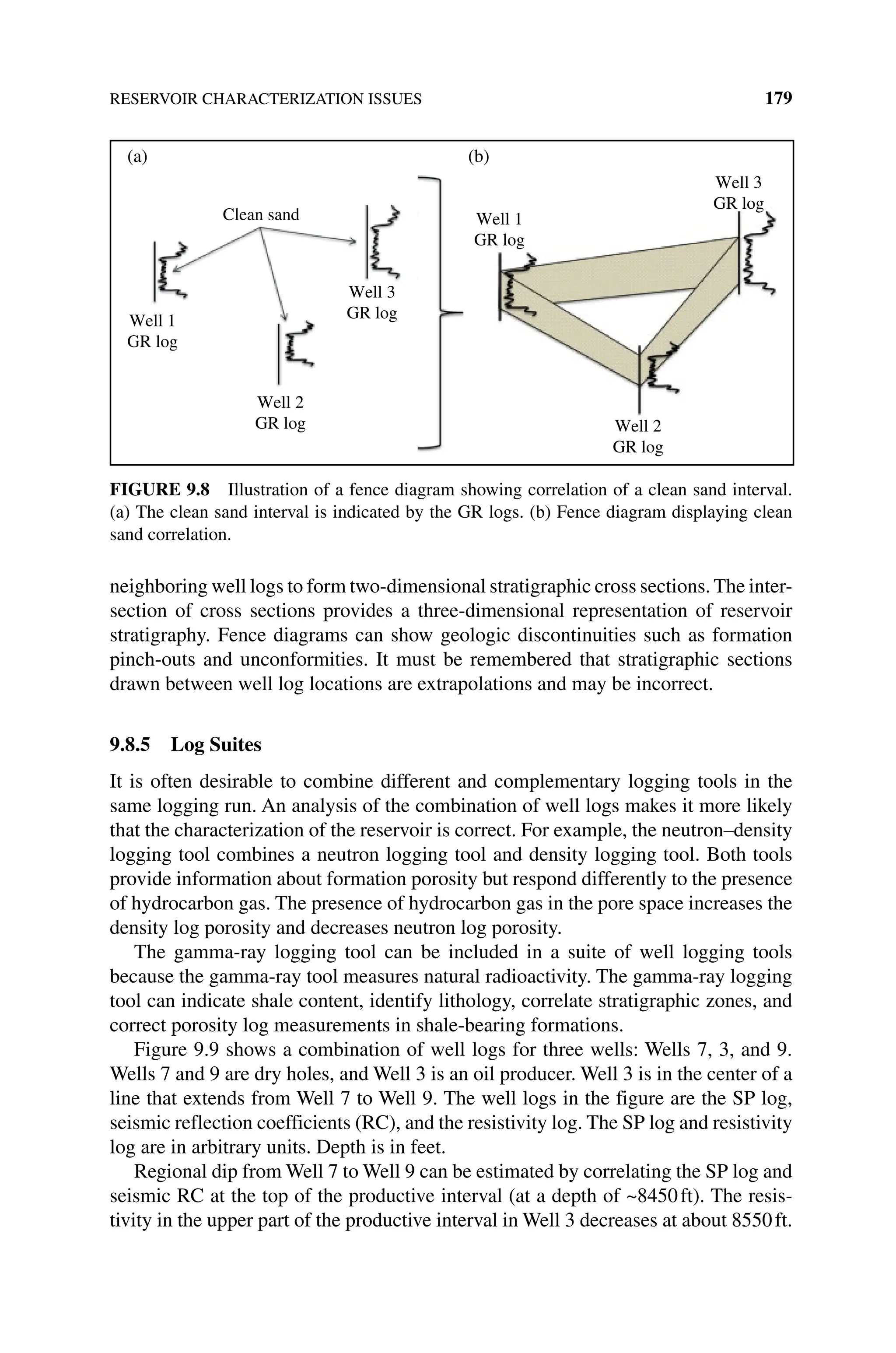

An example of the semilogarithmic plot for a PBU test is shown in Figure 12.3.

The plot is called a Horner plot.

The early time behavior of a Horner plot is displayed at large Horner times on

the right‐hand side of the plot. Later times correspond to smaller Horner times on

the left‐hand side of the plot. The wellbore storage effect appears as the rapid increase

of shut‐in pressure at early times in Figure 12.3 and does not end until Horner

time≈25. The infinite‐acting period appears as the straight line in the Horner time

Example 12.2 Horner Time

A well flows for 8hr with a stabilized rate before being shut in. Calculate

Horner time at a shut‐in time of 12hr.

Answer

The previous data gives Horner time t

t t

t

H

F 8 12

12

1 667

. .](https://image.slidesharecdn.com/introductiontopetroleumengineeringbyjohnr-241125084112-ea228c08/75/Introduction-to-Petroleum-Engineering-by-John-R-Fanchi-pdf-245-2048.jpg)