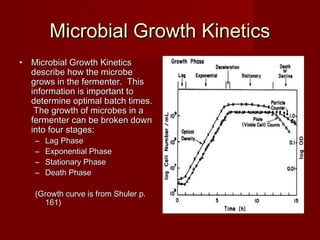

This document provides an introduction to fermentation processes. It discusses that Aspergillus niger and Lactobacillus are commonly used microbes to produce citric acid and lactic acid respectively in batch fermenters. It covers key areas of fermentation including microbial growth kinetics, media selection, sterilization, inoculum development, fermenter design, instrumentation and control, and aeration/agitation. Microbial growth is described through lag, exponential, stationary and death phases. Appropriate media containing essential nutrients is required. Heat sterilization of media is important. Inoculum is grown in seed fermenters to provide sufficient cell volumes. Factors like aeration, agitation, temperature/pH