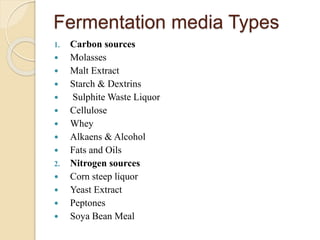

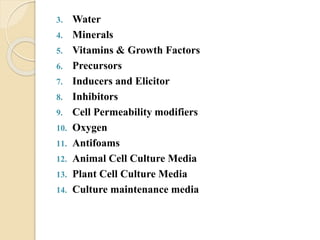

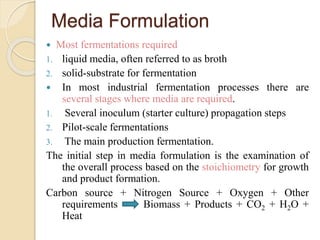

Fermentation media provides microorganisms with nutrients needed for growth and product formation. It consists of a carbon source, like molasses or starch, for energy and biosynthesis, along with nitrogen, minerals, vitamins and other trace elements. The choice of media components considers factors like cost, availability, ease of handling, and their effects on microbial physiology and fermentation performance. Carbon sources fuel both cell growth and metabolism, while nitrogen sources support biosynthesis. A variety of industrial byproducts can serve as nutrients in fermentation, with the specific media tailored to the microorganism and fermentation process.