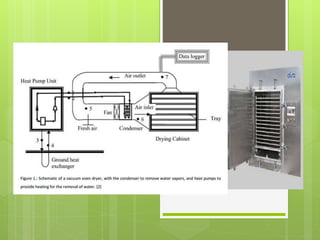

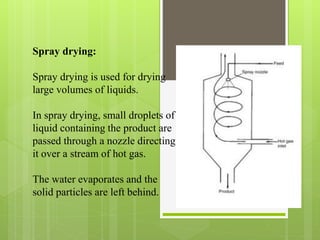

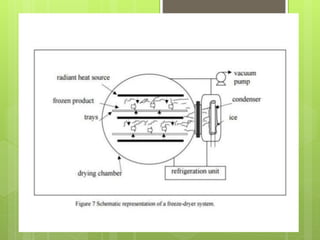

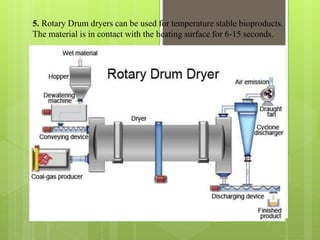

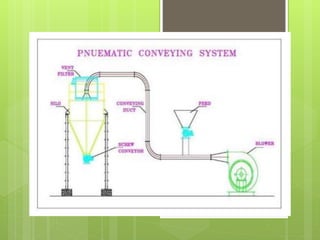

Drying is an essential process that involves transferring heat to remove moisture from wet products. Common drying methods include vacuum tray drying, freeze drying, rotary drum drying, spray drying, and pneumatic conveyor drying. Vacuum tray drying works by removing moisture through a vacuum, while spray drying uses nozzles to spray liquid droplets into a heated gas stream to evaporate water. Freeze drying preserves biological activity by freezing and then applying a vacuum to directly sublimate ice. Rotary drum dryers use a heated, rotating cylinder to dry materials, and pneumatic conveyor dryers suspend particles in a heated air stream to dry reasonably solid feeds.