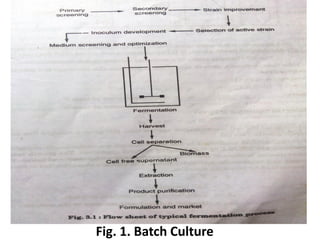

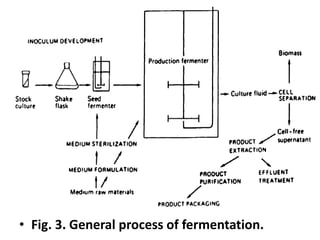

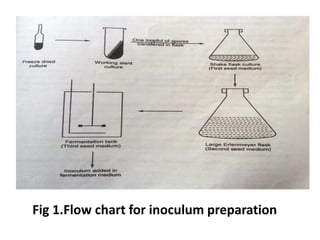

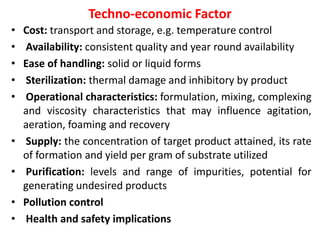

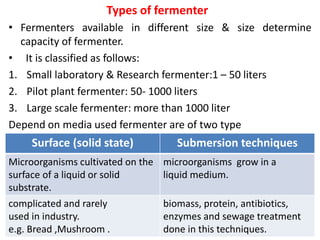

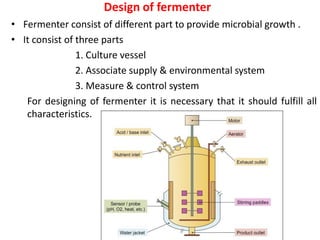

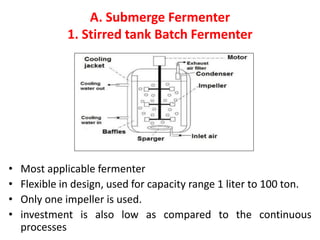

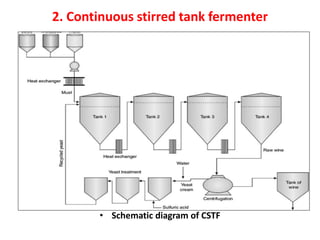

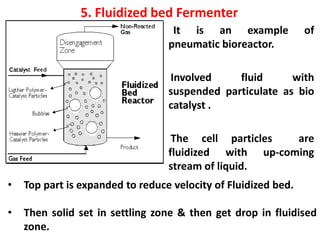

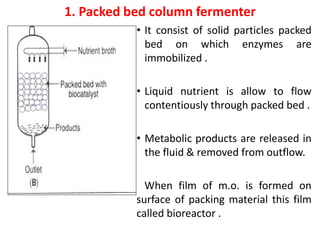

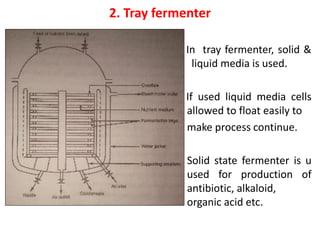

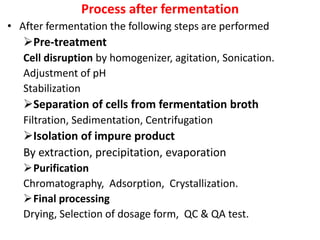

This document discusses fermentation and the fermentation process. It defines fermentation as the process of growing microorganisms in a nutrient medium while maintaining physical and chemical conditions to convert the nutrients into a desired product. It describes different types of fermenters used including submerged and surface fermenters. Key factors for fermentation are also outlined such as pure culture, sterilized medium, inoculum development, production fermenter, and equipment for processes like medium drawing, cell separation, product collection and purification.