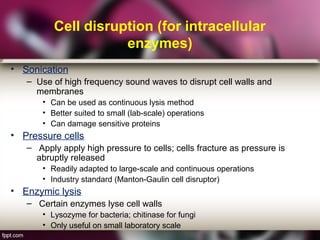

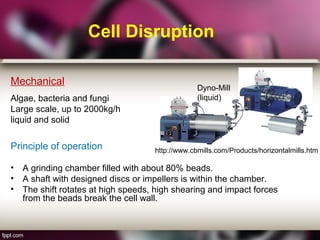

The document discusses various methods for recovering and purifying fermentation products. It describes how extraction is used to separate products from cells, including mechanical methods like homogenization and non-mechanical methods like solvent extraction. Purification techniques covered include precipitation, centrifugation, filtration, chromatography, electrophoresis, crystallization and drying which are used to separate and purify products based on properties like size, charge and solubility. The level of purification depends on the intended use of the product.