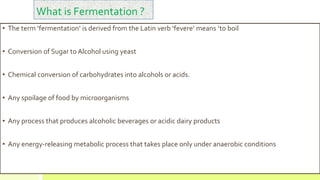

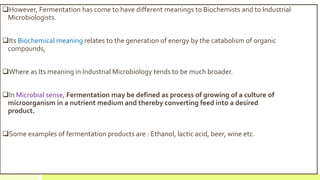

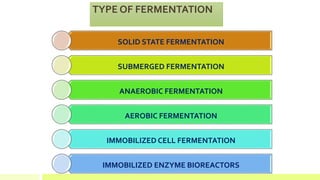

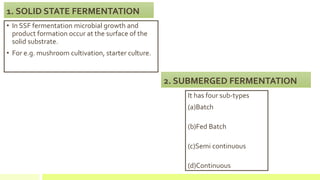

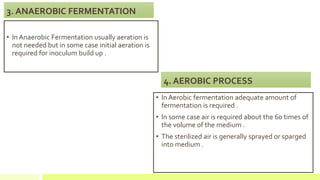

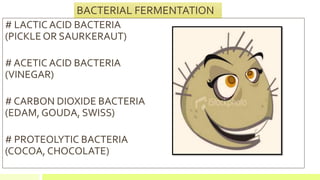

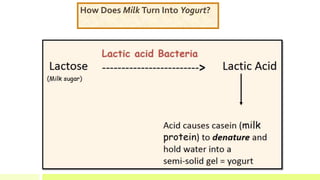

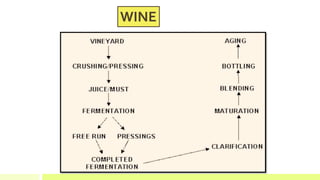

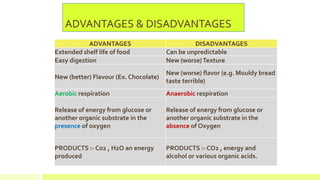

Fermentation is defined as the conversion of carbohydrates like sugars and starches into alcohol and acids through the metabolic process of microorganisms like yeast and bacteria under anaerobic conditions. There are several types of fermentation including solid state fermentation, submerged fermentation, anaerobic fermentation, and aerobic fermentation. Key factors that affect fermentation include temperature, pH, oxygen levels, and nutrients available to the microorganisms. Common examples of fermentation products include yogurt, wine, beer, and bread.