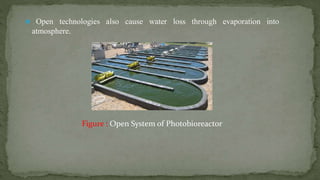

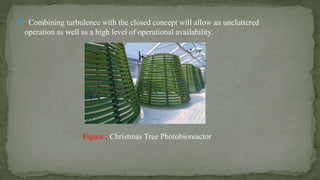

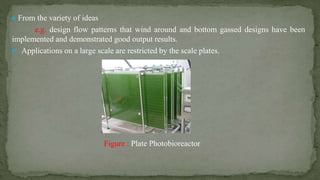

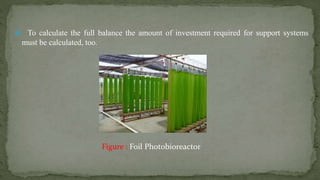

This document defines a photobioreactor as a device that uses solar light to transform organic material into biomass. It discusses open and closed photobioreactor systems. Open systems include raceway ponds, which have lower costs but less control over conditions. Closed systems have reduced risks but higher costs. The document then describes five types of closed photobioreactors: tubular, Christmas tree, plate, horizontal, and foil designs. It notes advantages and disadvantages of different designs.