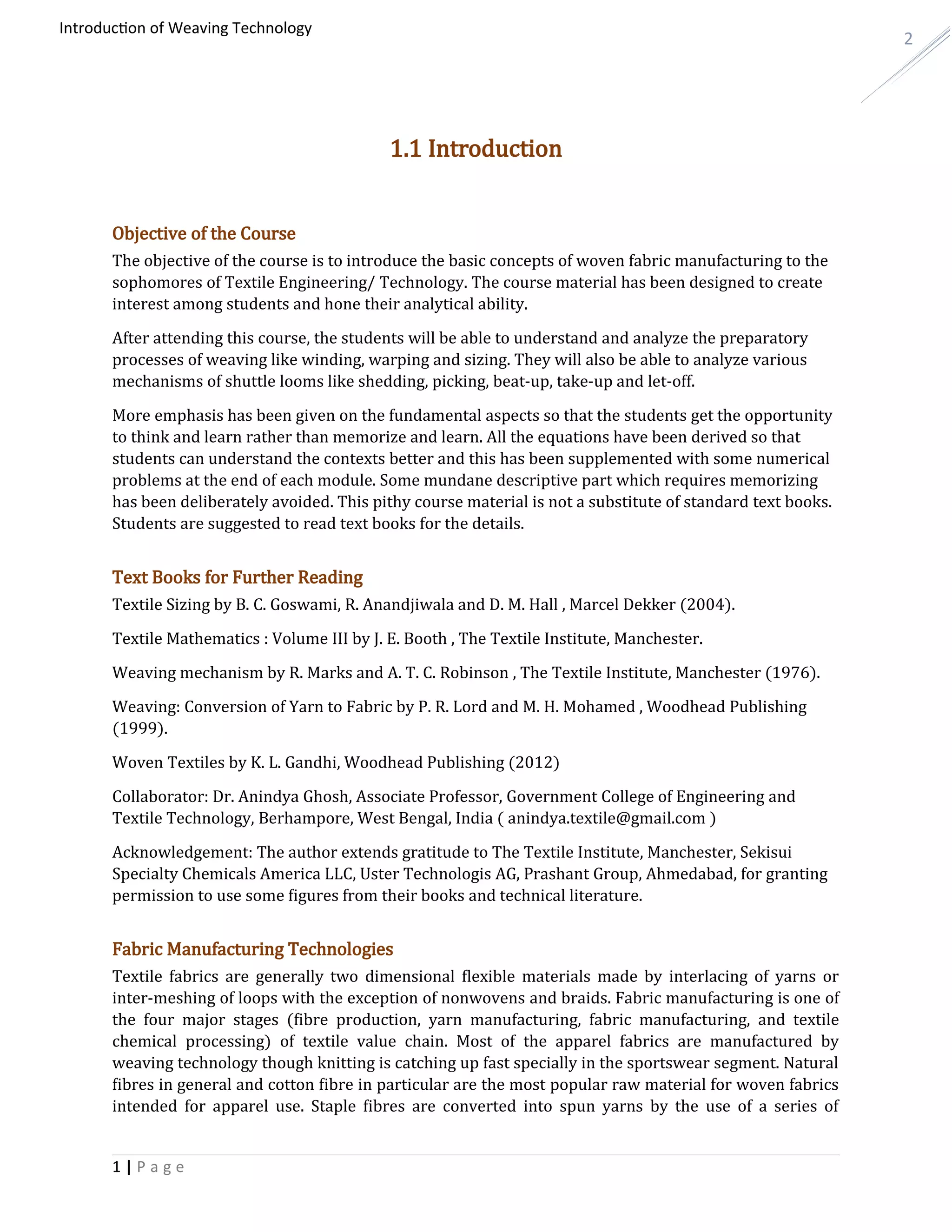

The document introduces a course on weaving technology aimed at textile engineering students, focusing on the manufacturing processes of woven fabrics. It covers yarn preparation, loom operations, and the various types of looms used, emphasizing analytical understanding rather than memorization. Additionally, it outlines properties and classifications of fabrics, as well as essential definitions related to woven textiles.