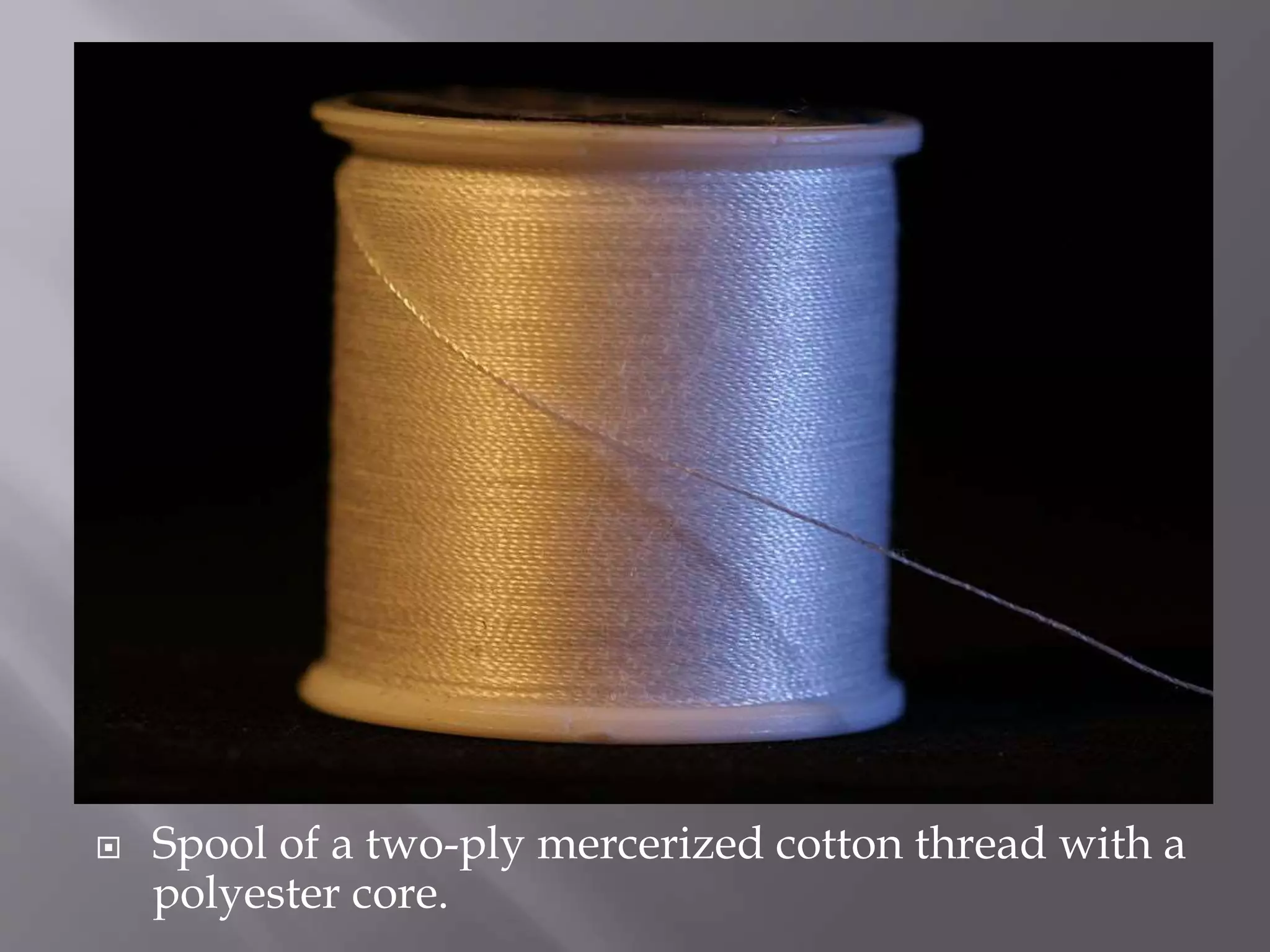

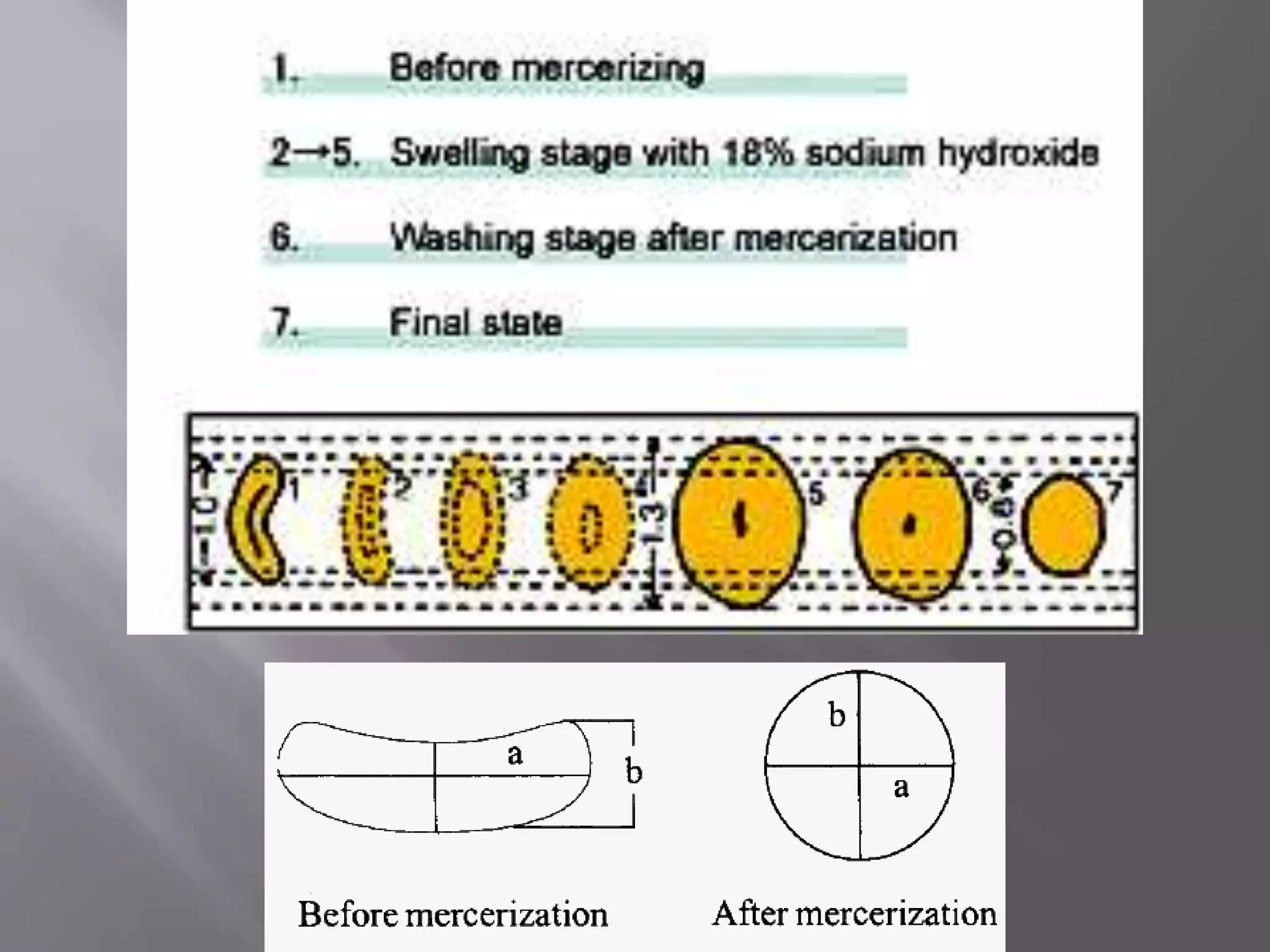

Mercerization is a process that treats cotton fabrics with a cold sodium hydroxide solution. This treatment causes the cotton fibers to swell and gives the fabric an increased luster and strength. John Mercer discovered the process in 1844, though it did not become popular until H.A. Lowe improved it in 1890 by preventing shrinkage during treatment. The modern process involves bathing cotton thread in sodium hydroxide then neutralizing it with an acid. This increases the thread's luster, strength, dye affinity, and mildew resistance. Mercerization results in fiber swelling and morphology changes that allow for more dye absorption and a brighter colored fabric with better color retention after washing.