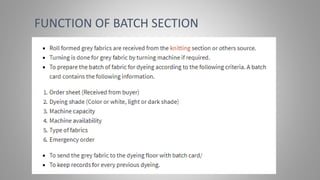

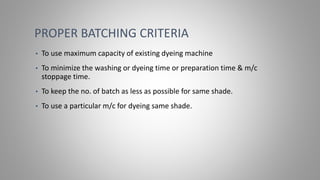

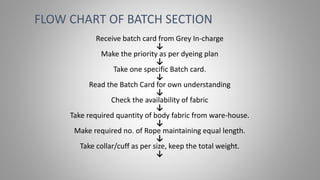

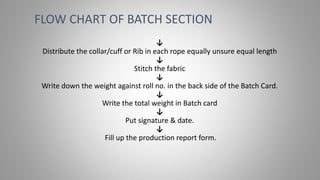

The document discusses the batch section process in dyeing fabrics. The batch section prepares fabrics to be dyed by grouping them into batches based on criteria like dyeing machine capacity, minimizing preparation time, and keeping batches for the same shade together. The batching manager plans initial batches considering these criteria. The batch section receives this plan and may adjust it based on machine conditions or emergencies. The key steps of batching include receiving fabric cards, prioritizing fabrics, checking availability, weighing and bundling fabrics, and documenting weights on cards before sending fabrics for dyeing.