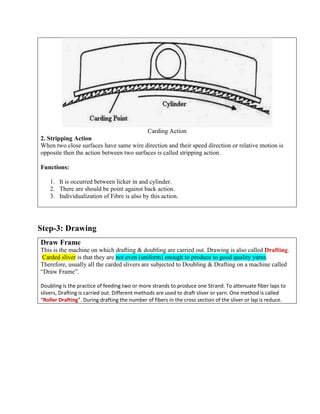

The document discusses the process of cotton yarn spinning from start to finish. It begins with the cotton fiber growing in bolls on the cotton plant. The fibers then undergo various cleaning and preparation processes. The main steps of yarn spinning involve blowroom preparation, carding, drawing, combing (optional), roving, ring spinning, and cone winding. Each step performs important functions like opening, cleaning, drafting, twisting, and winding the fibers into yarns of increasing fineness and uniformity ready for further textile manufacturing. Ring spinning is described as the most common method and produces strong, fine yarns suitable for many applications.